Electric planer

An electric planer, the technology on the other side, applied in the direction of manual planing, processing machines for manufacturing flat surfaces, wood processing appliances, etc., can solve the problems of complex structure, low adaptability, etc. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

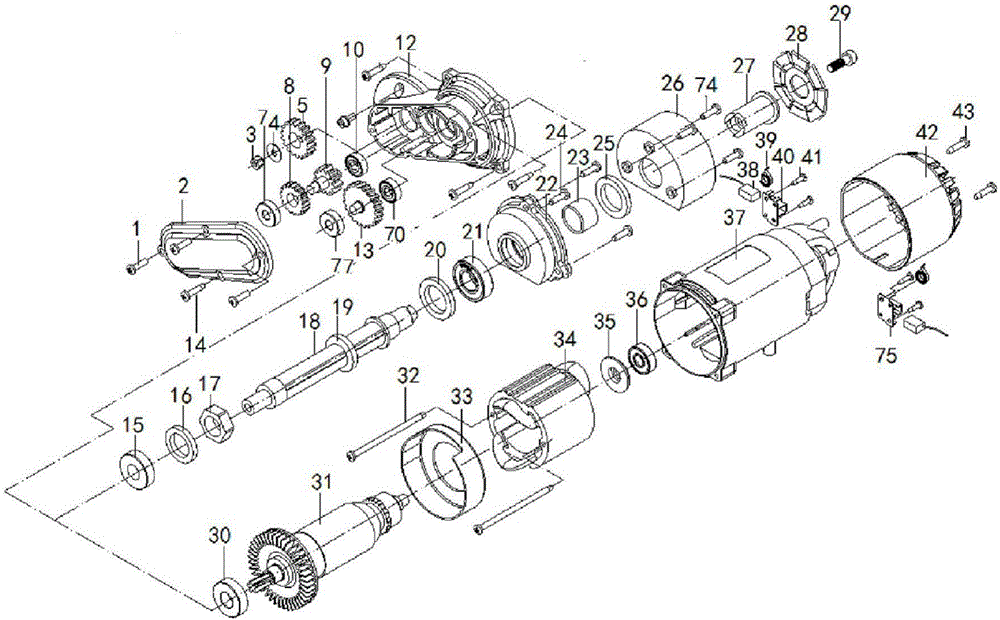

[0031] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, an electric planer, the front cover 2 is connected to the gear box 12 through the cross pan head screw 1 and the cross pan head self-tapping screw 14, and the secondary cutter shaft gear 5 is connected to the gear box 12 through the nut 3 and the gasket 4. The inner cavity is connected, one side of the middle pinion 9 is connected with the first bearing 7 and the middle plate tooth 8, the other side of the middle pinion 9 is connected with the second bearing 10, and the outer circumferences of the second bearing 10 and the fourth bearing 70 are respectively connected The inner cavity of the gear box 12, the outer circumferences of the first bearing 7 and the third bearing 77 are respectively connected to the inner cavity of the front cover 2, one side of the first-stage large gear 13 is connected to the third bearing 77, and the other side of the f...

Embodiment 2

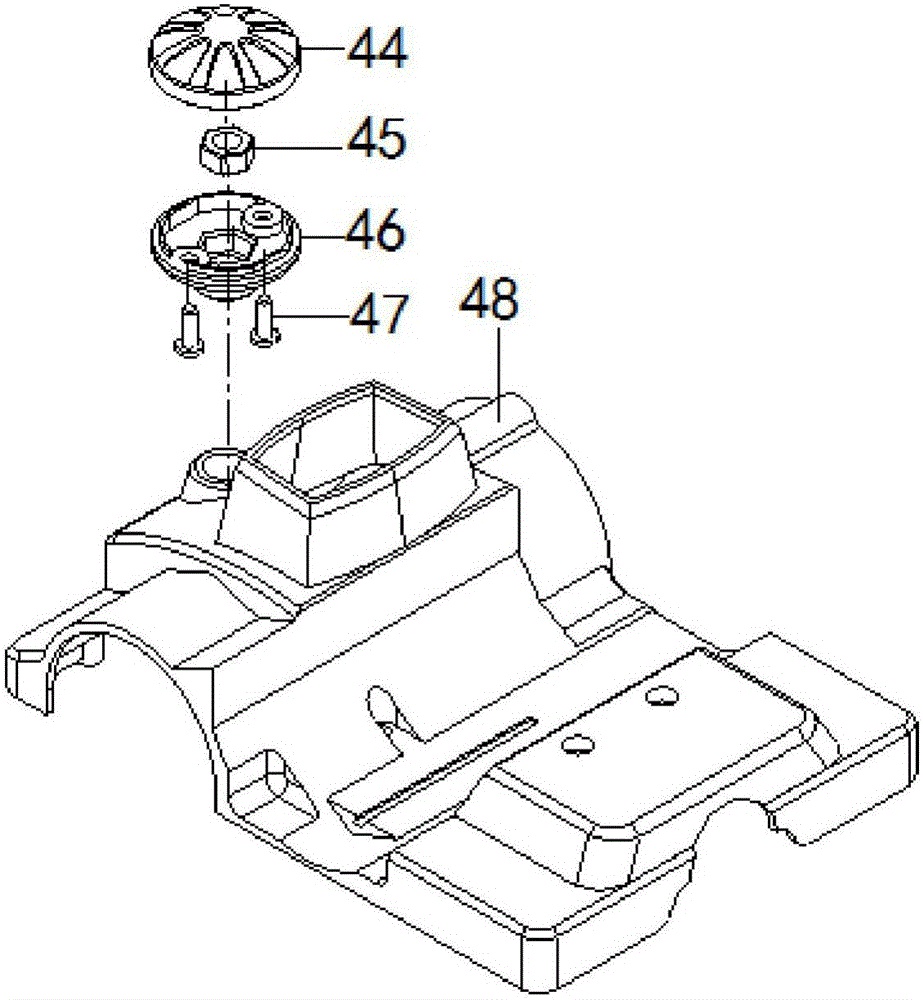

[0033] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 As shown, an electric planer, the adjustable structure of the bottom plate adopts double springs and single screws to expand and contract, and the rear screw is used for positioning, which makes the adjustment more balanced, and the adjustment size is enlarged. Changing the original single spring positioning balance is easy to fail.

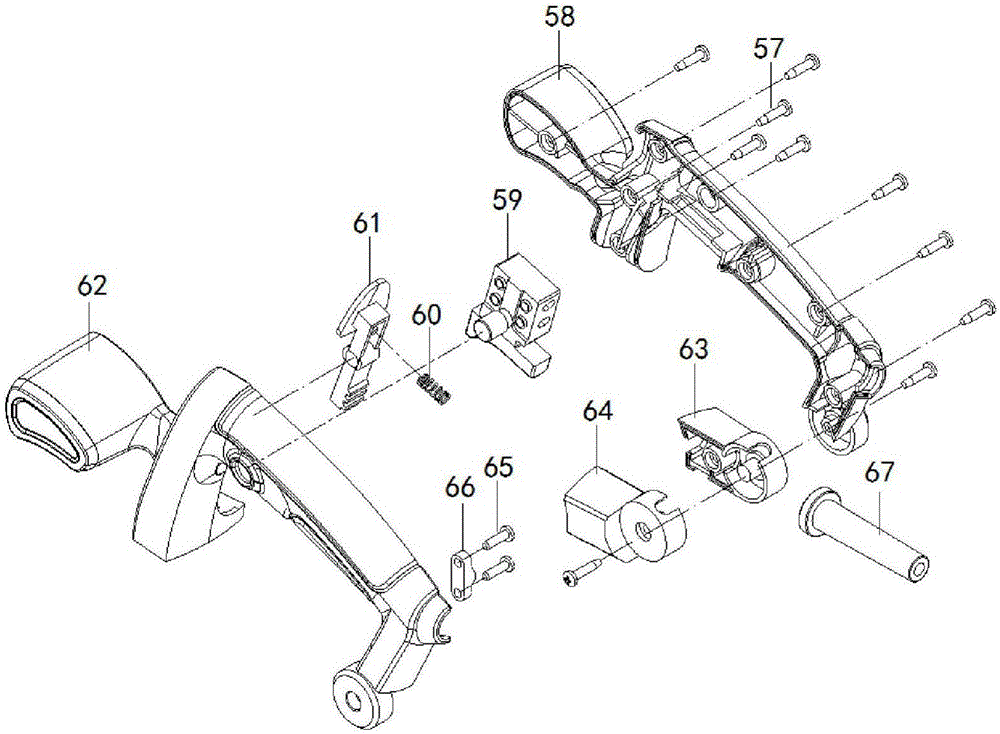

[0034] like Figure 9 , Figure 10 As shown, the cutter shaft 18 is connected to the wall scraping tool, the rust removal tool and the irregularly dislocated special-shaped knife, and the wall scraping tool is an irregularly dislocated special-shaped knife 80; Figure 11 As shown, the derusting tool adopts a circular wire structure; Figure 12 As shown, the irregularly dislocated special-shaped knife is adopted, and the outer circumference of the knife holder 82 of the irregularly dislocated special-shaped knife...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com