Cleaner

A vacuum cleaner and filter technology, applied in the direction of vacuum cleaners, cleaning filter devices, cleaning equipment, etc., can solve problems such as reduced suction, clogged suction units, abnormalities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

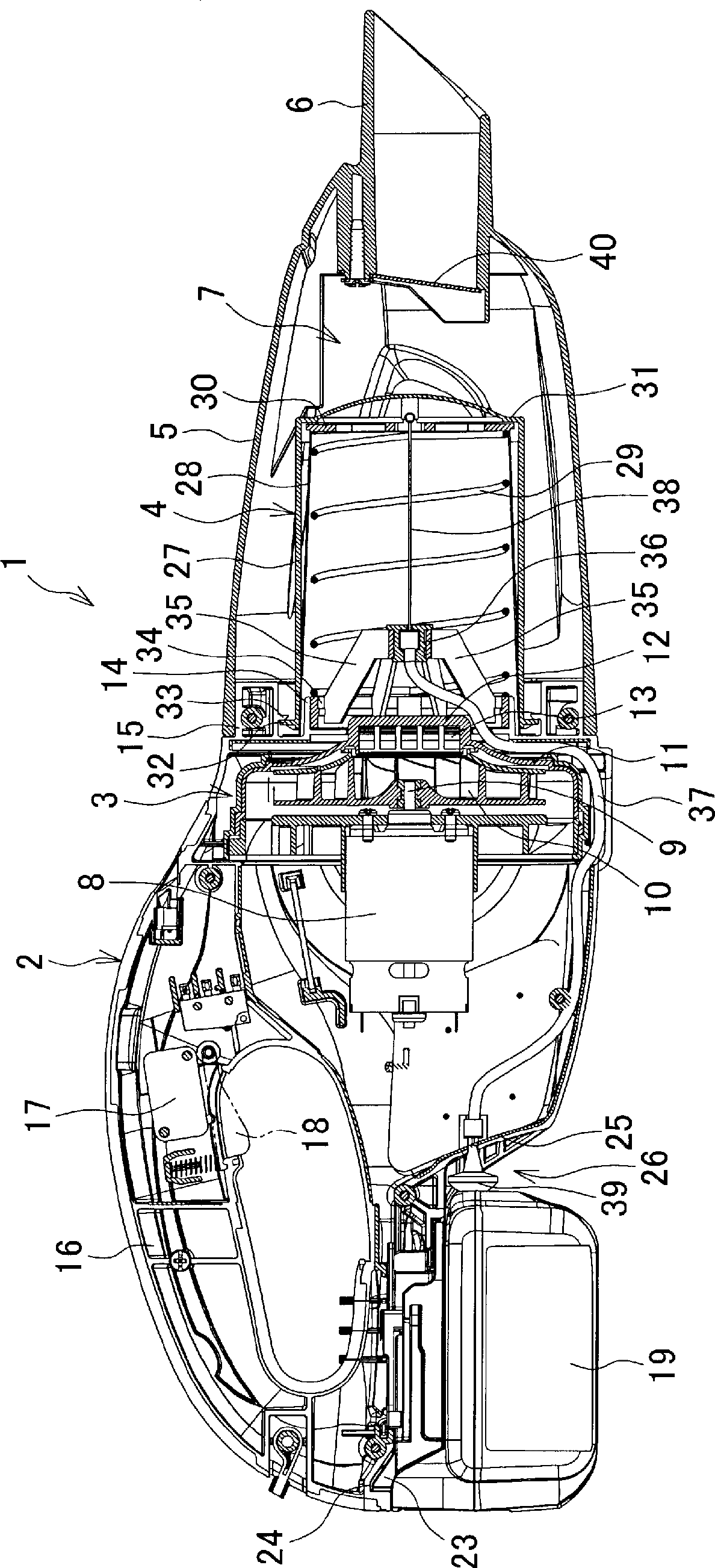

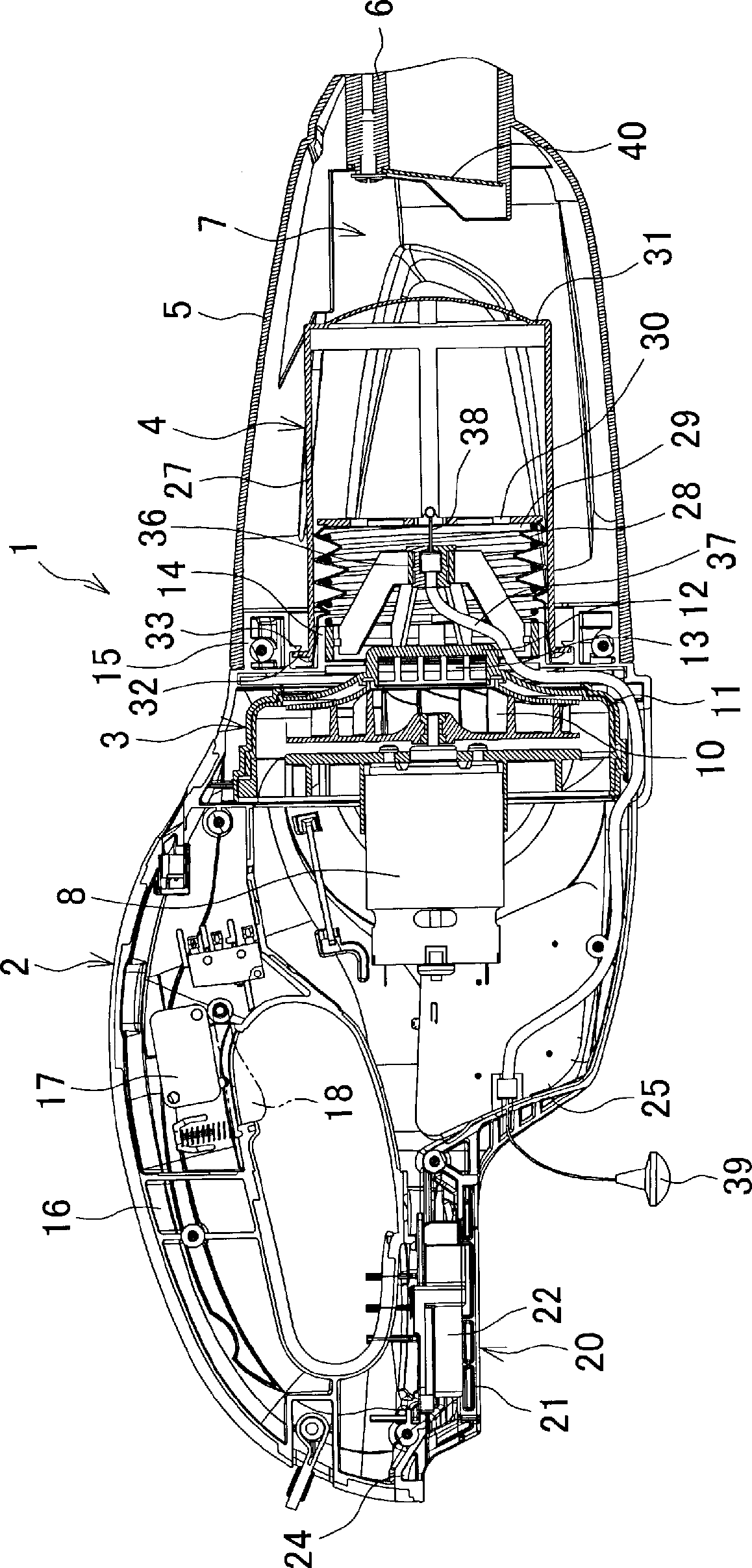

[0015] Embodiments of the present invention will be described below based on the drawings.

[0016] figure 1 It is a longitudinal sectional view of a rechargeable vacuum cleaner (hereinafter referred to as "vacuum cleaner"). The vacuum cleaner 1 accommodates the suction unit 3, and the front surface (referred to as figure 1 The right side is the front) the main body casing 2 of the filter unit 4 protrudes, and the capsule-shaped front side casing 5 is installed. The front side casing 5 has a cylindrical suction port 6 at the front end and forms a dust collection chamber inside. 7.

[0017] The suction unit 3 is formed so that the suction fan 10 fixed to the output shaft 9 of the motor 8 is covered with a cover 11, and the central part 12 of the cover 11 protrudes forward from the center of the front surface of the main body case 2 to form a suction port. 13. On the front surface of the main body casing 2, an inner ring 14 coaxially surrounding the central portion 12 and prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com