Wiring structure of induction layer

A wiring structure and sensing layer technology, which is applied in the field of wiring structure of a single-layer sensing layer, can solve the problems of difficult detection of touch edge coordinates and small edge sensing area, and achieve the effects of easy edge coordinates, easy detection, and increased sensing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

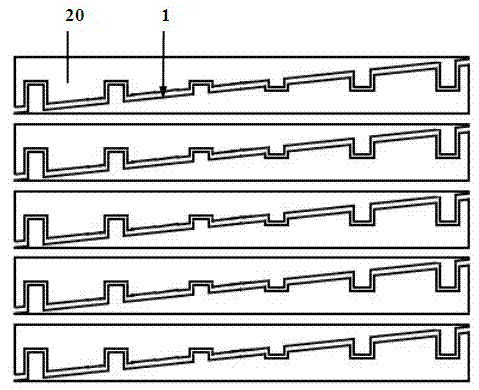

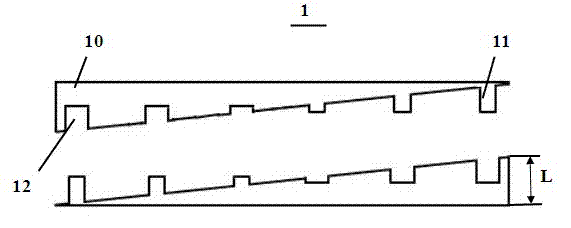

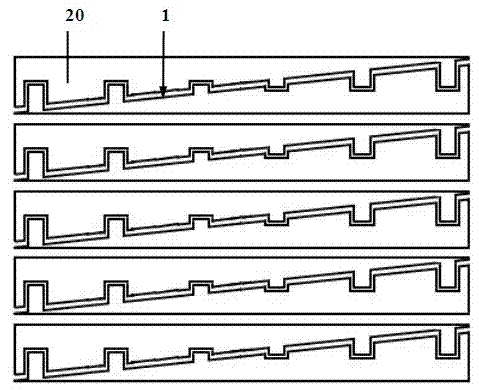

[0011] Please refer to figure 1 and figure 2 , the wiring structure of the sensing layer involved in the present invention, the sensing layer includes a plurality of vertically arranged touch electrode groups 1, and the touch electrode group 1 includes two opposing touch electrodes 20, that is, one of the touch electrodes 20 is rotated 180 degrees clockwise relative to the other touch electrode 20 . The opposite edges of the two touch electrodes 20 in the touch electrode group 1 are facing edges.

[0012] The touch electrode 20 includes a main body 10 , the longitudinal width L of the main body 10 gradually decreases from one end to the other end, and the shape of the main body 10 may be a triangle, a trapezoid or other figures whose longitudinal width gradually decreases from one end to the other end. The main body 10 is provided with at least one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com