Luminescence module

A light-emitting module and light source technology, applied in optics, light guides, electric light sources, etc., can solve the problems of material cost, uneven light output on the light-emitting surface, etc., and achieve the effect of improving linear bright lines and uniform light-emitting brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

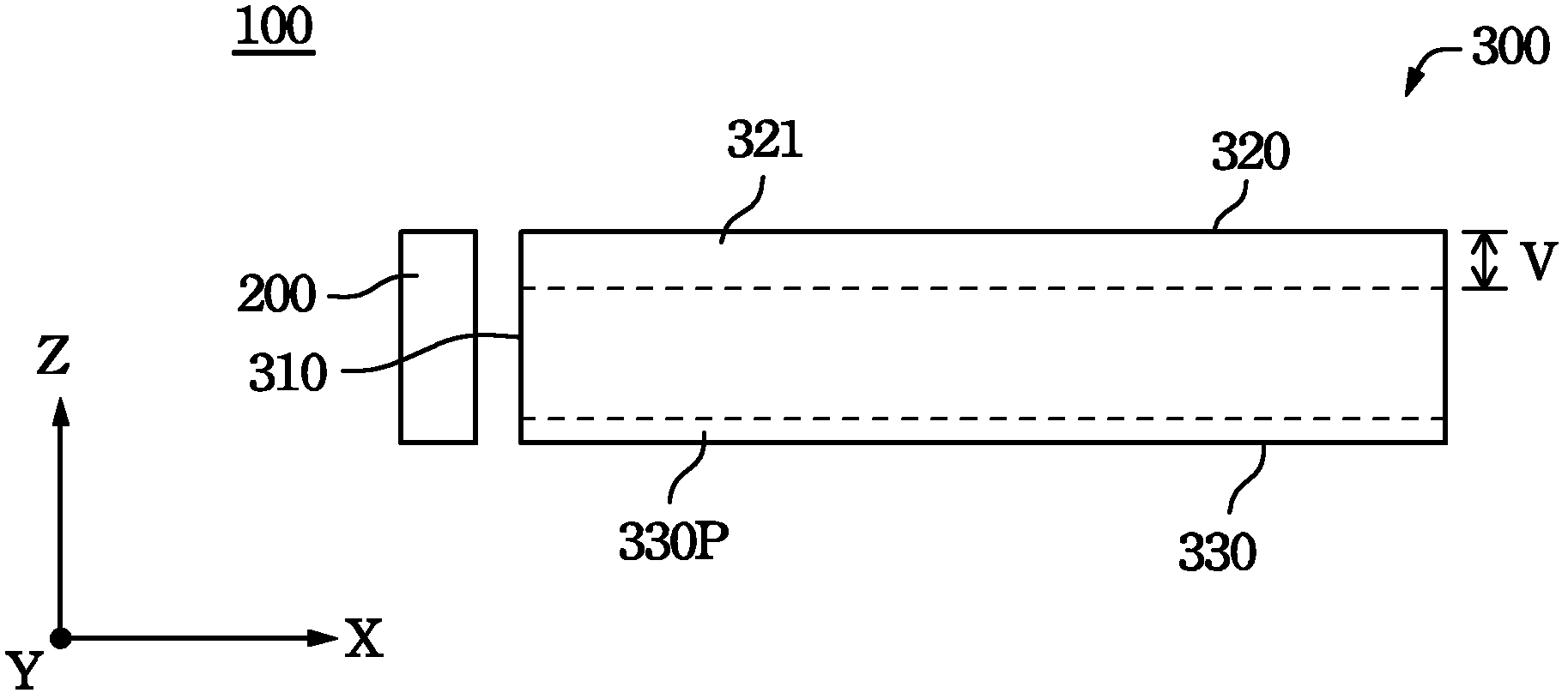

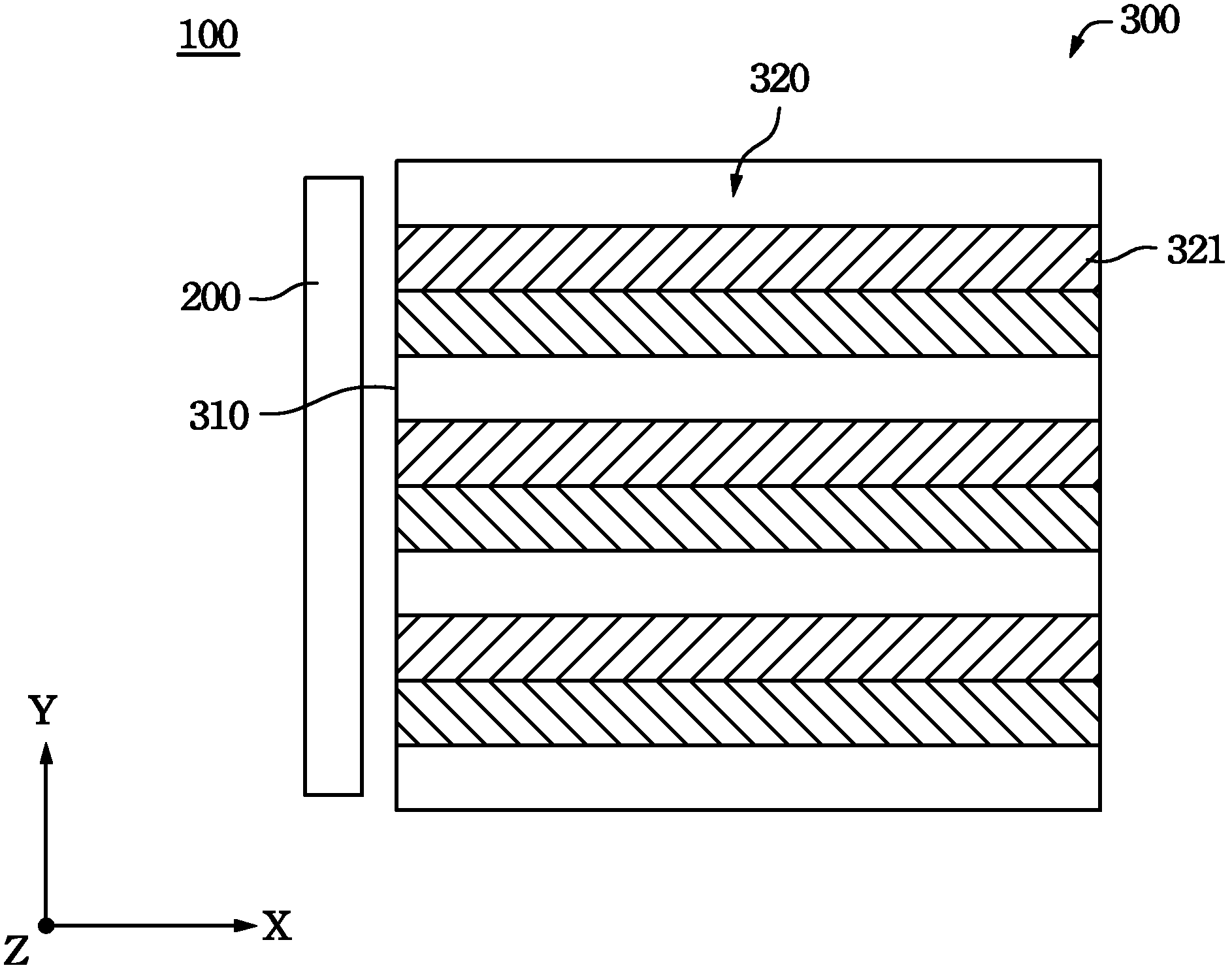

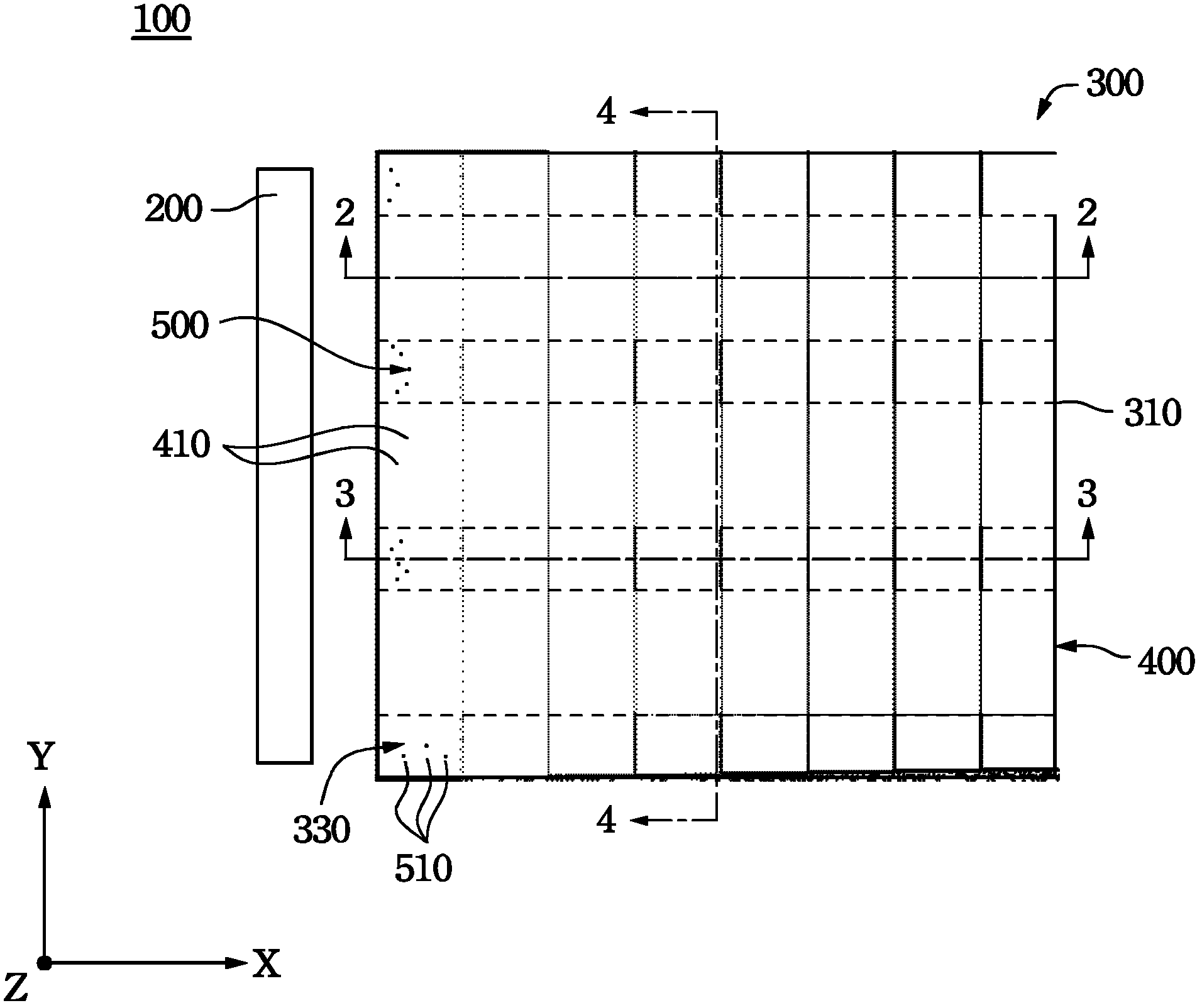

[0046] The light-emitting module provided by the present invention includes a first light source and a light guide plate. The light guide plate includes a first light-incident surface, a light-emitting surface, a reflective surface, a plurality of first microstructure dot groups and a second microstructure dot group. The light-emitting surface includes a plurality of linear three-dimensional units arranged in parallel and spaced apart on the light-emitting surface. The reflecting surface and the light emitting surface are opposite to each other. The first light incident surface is between the light exit surface and the reflective surface, and the first light source emits light toward the first light incident surface. The first microstructure dot group is respectively fully located in one of the vertical projection positions of the linear three-dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com