Wireless network monitoring system of welding production workshop

A wireless network and monitoring system technology, applied in signal transmission system, electrical signal transmission system, energy industry, etc., can solve problems such as uncontrollable welding equipment, difficult field wiring, incomplete monitoring of welding parameters, etc., to achieve convenient and quick reset Set and adjust, solve the effect of wiring difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

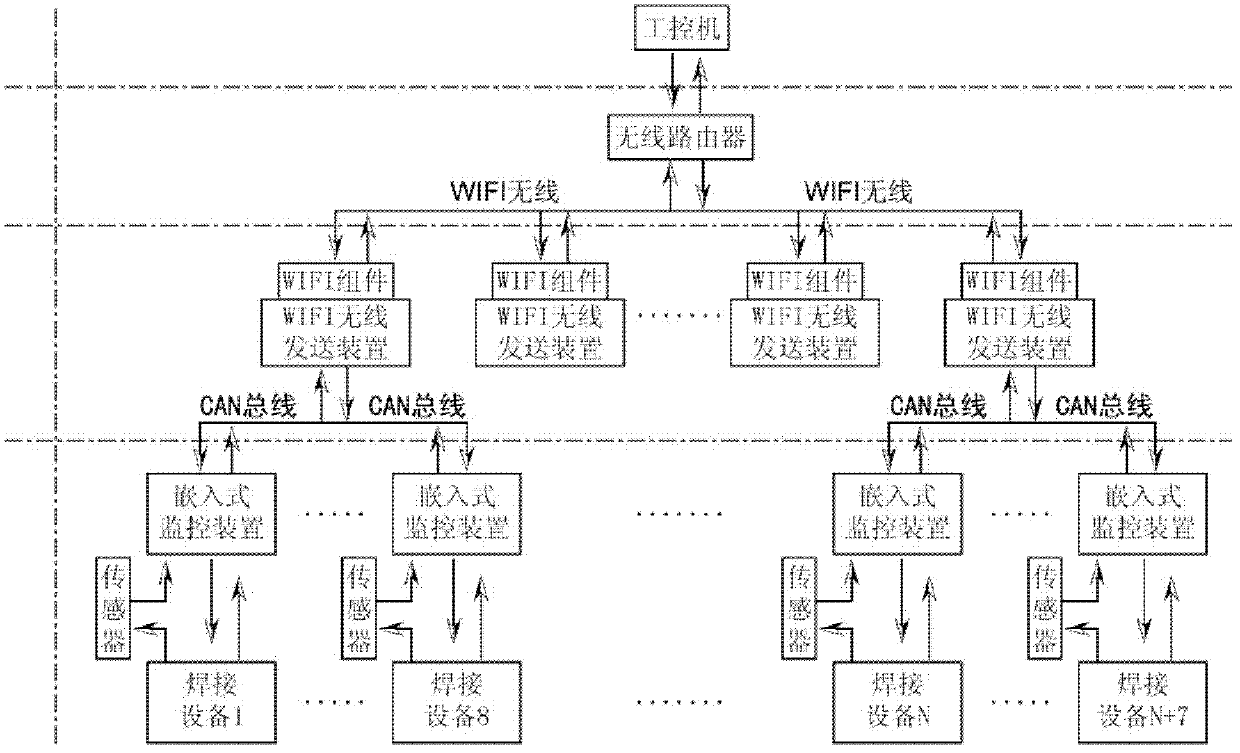

[0038] The technical scheme of the present invention is as figure 1 As shown, in order to achieve the above object, the present invention adopts the following technical solutions: including welding equipment, sensors, embedded monitoring devices, WIFI transmission devices, WIFI components, wireless routers and industrial computers.

[0039] in:

[0040] The sensors include a Hall current sensor, a Hall voltage sensor and a flow meter, which are used to measure the welding current, arc voltage, and gas flow of the welding equipment, and the output terminals of each sensor are connected to the corresponding port of the embedded monitoring device.

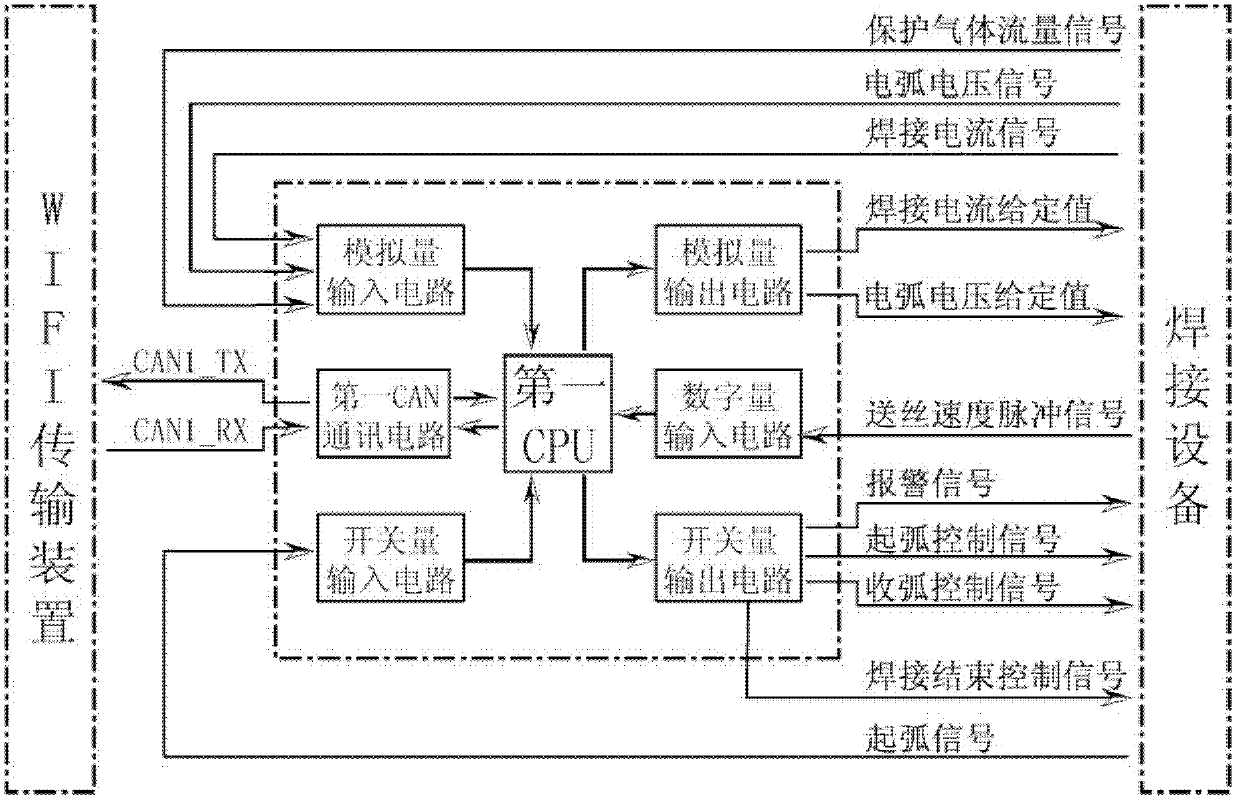

[0041] Embedded monitoring devices such as figure 2 As shown, it is used to monitor the welding current, arc voltage, wire feeding speed, arc starting signal and gas flow of the welding equipment, set the welding current and arc voltage of the welding power supply, and send the arc starting control signal and arc closing to the weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com