Novel automobile speed change joystick

A shift lever and lever technology, applied in vehicle parts, control devices, transportation and packaging, etc., can solve the problems of shortening the service life of the shift control mechanism, frequent lever movement, easy damage and failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

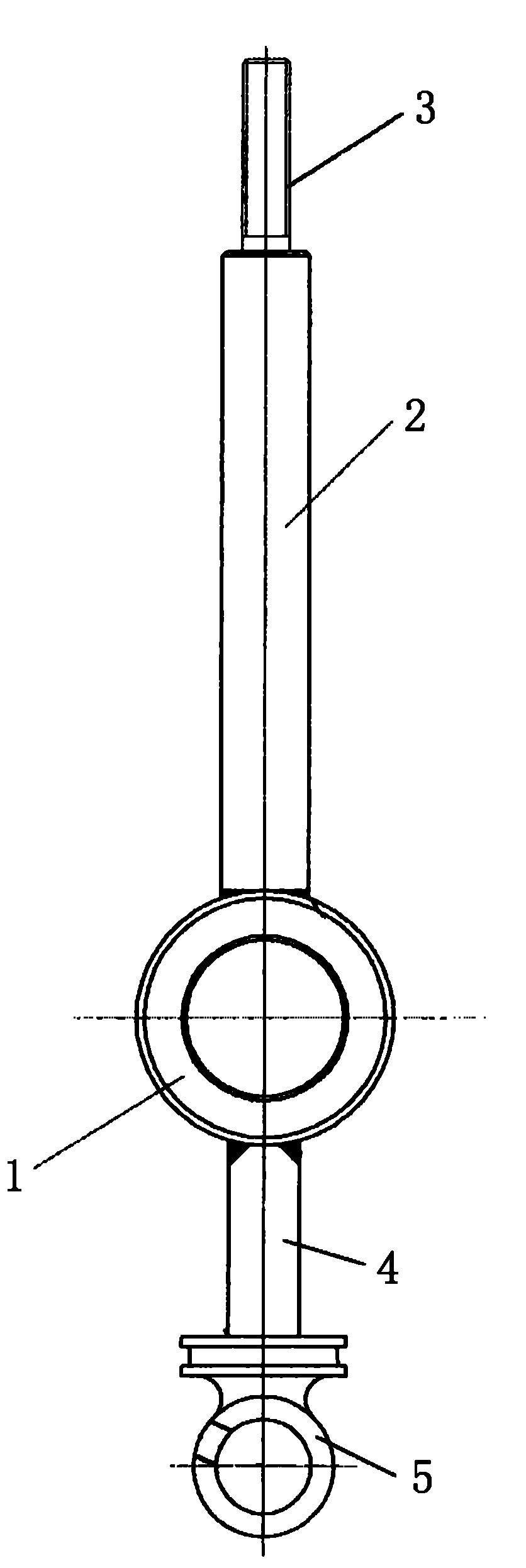

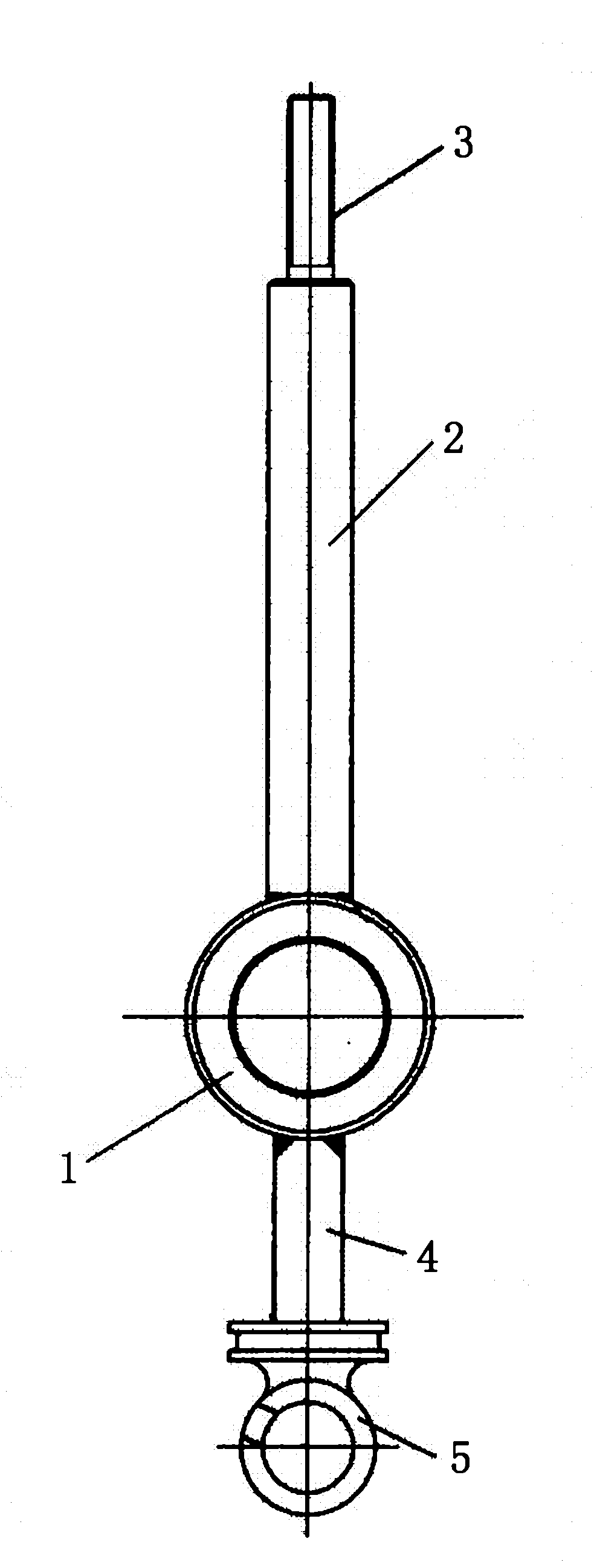

[0008] Such as figure 1 As shown, the present invention is connected with a joystick 2 on the upper side of the bearing fixed sleeve 1, and a connecting bolt 3 is arranged on the upper end of the joystick 2, and the fixed shaft 4 is arranged on the lower side of the bearing fixed sleeve 1, and the bearing fixed sleeve 1 , The joystick 2 and the fixed shaft 4 are on the same axis, and the coupling sleeve 5 is located at the lower end of the fixed shaft 4 . Through the above arrangement, ball bearings are inlaid in the bearing fixing sleeve 1 of the present invention, and the coupling sleeve 5 is connected with the transmission telescopic rod of the automobile, so that the automobile transmission becomes light and flexible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com