Automobile door board with locking mechanism

A locking mechanism and a car panel technology, which is applied to the field of vehicle car panels, can solve the problems of complex structure of the locking mechanism, large space occupation, increased vehicle weight and manufacturing cost, etc., and achieves the effects of light weight, material saving and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

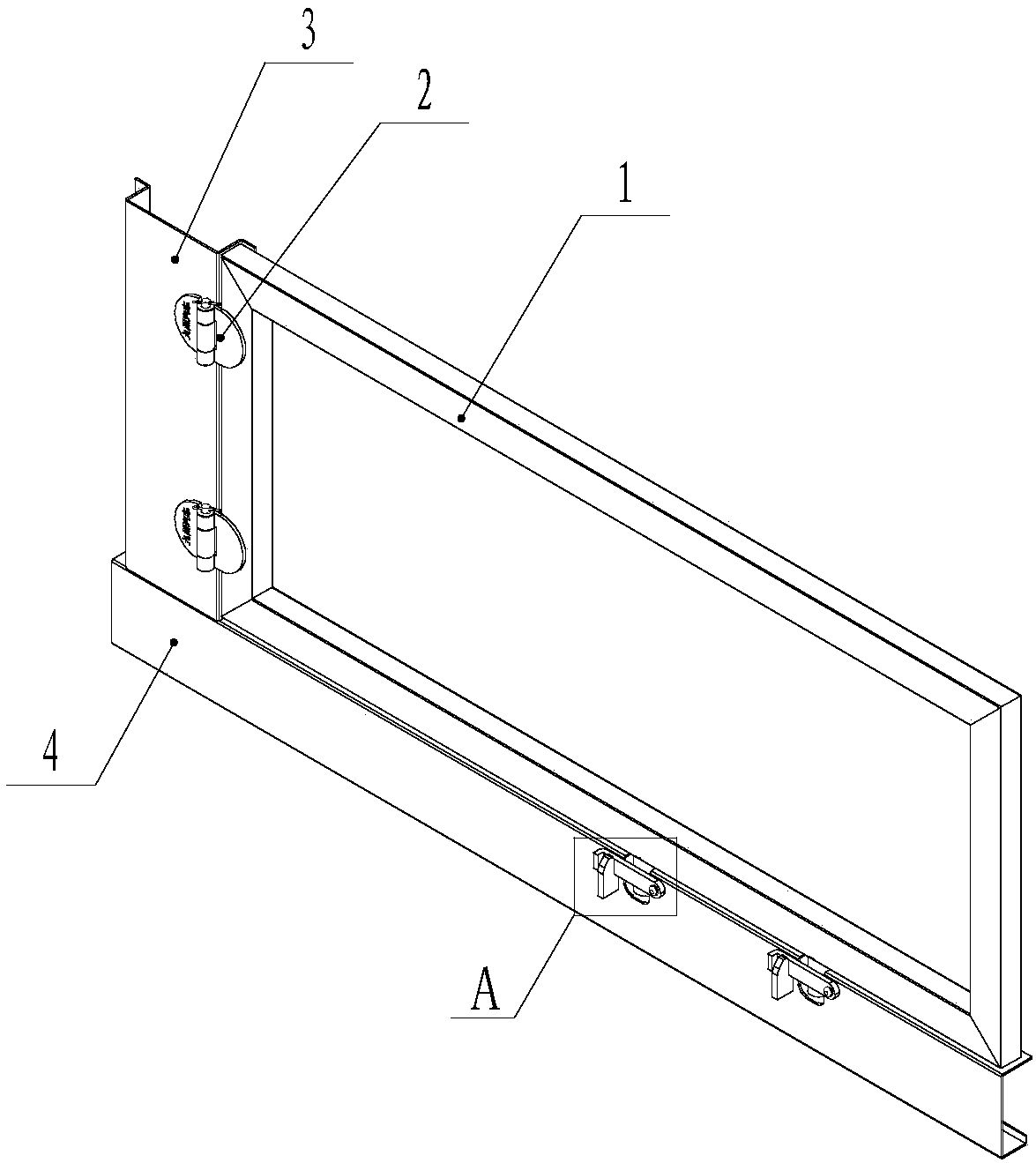

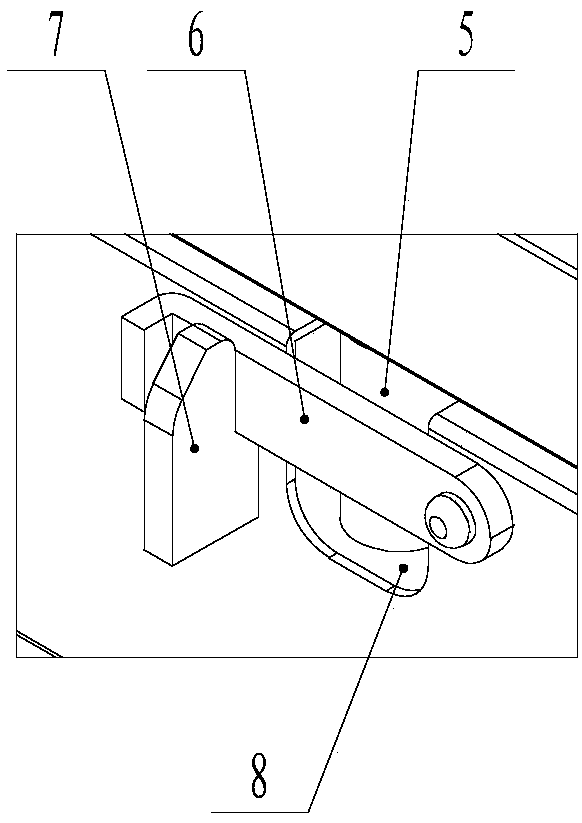

[0023] Such as figure 1 , figure 2 As shown, the vehicle panel provided with the locking mechanism according to the embodiment of the present invention includes a panel 1, a column 3 and a side beam 4, one end of the panel 1 is connected to the column 3 through a hinge 2, and the panel 1 is connected to the column 3 through a hinge 2. The bottom of the board 1 is provided with at least one set of downwardly protruding lock heads 5. As shown in the figure, there are two sets of lock heads 5. Increasing the number of lock heads 5 can effectively increase the connection strength of the locking mechanism. A lock groove 8 corresponding to the lock head 5 is provided, and the lock head 5 is embedded in the lock groove 8 when the compartment plate 1 is closed. The cooperation of the lock groove 8 is sufficient, and the lock head 5 can break away from the lock groove 8 when the compartment panel 1 is opened, and the side beam 4 is also provided with a lock buckle for limiting the lo...

Embodiment 2

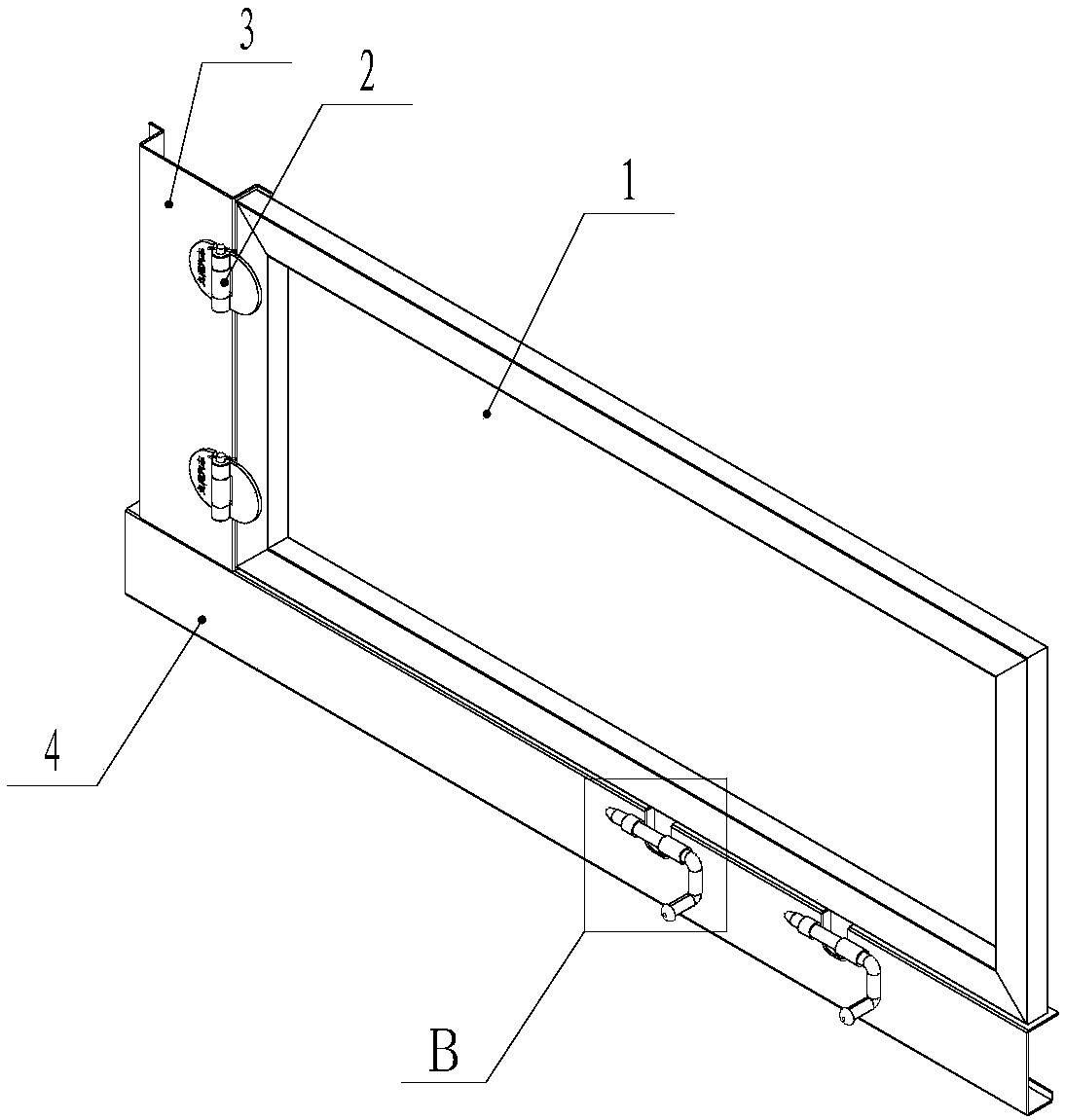

[0026] Such as image 3 , Figure 4 As shown, the vehicle panel provided with the locking mechanism according to the embodiment of the present invention includes a panel 1, a column 3 and a side beam 4, one end of the panel 1 is connected to the column 3 through a hinge 2, and the panel 1 is connected to the column 3 through a hinge 2. The bottom of the board 1 is provided with at least one set of downwardly protruding lock heads 5, and two sets of lock heads 5 are shown in the figure. Increasing the number of lock heads 5 can effectively increase the connection strength of the locking mechanism. A lock groove 8 corresponding to the lock head 5 is provided, and the lock head 5 is embedded in the lock groove 8 when the compartment plate 1 is closed. The cooperation of the lock groove 8 is sufficient, and the lock head 5 can break away from the lock groove 8 when the compartment panel 1 is opened, and the side beam 4 is also provided with a lock buckle for limiting the lock hea...

Embodiment 3

[0029] Such as Figure 5 , Figure 6 As shown, the vehicle panel provided with the locking mechanism according to the embodiment of the present invention includes a panel 1, a column 3 and a side beam 4, one end of the panel 1 is connected to the column 3 through a hinge 2, and the panel 1 is connected to the column 3 through a hinge 2. The bottom of the board 1 is provided with at least one set of downwardly protruding lock heads 5, and two sets of lock heads 5 are shown in the figure. Increasing the number of lock heads 5 can effectively increase the connection strength of the locking mechanism. A lock groove 8 corresponding to the lock head 5 is provided, and the lock head 5 is inserted into the lock groove 8 when the compartment panel 1 is closed. It only needs to cooperate with the lock groove 8. When the compartment panel 1 is opened, the lock head 5 can break away from the lock groove 8, and the side beam 4 is also provided with a lock to limit the lock head 5 from bre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com