High-precision coder

A technology of high-precision encoders and coding wheels, which is applied in the direction of instruments, conversion sensor output, measuring devices, etc., can solve the problem that it cannot be lower than a certain value, and achieve the effect of improving the physical resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

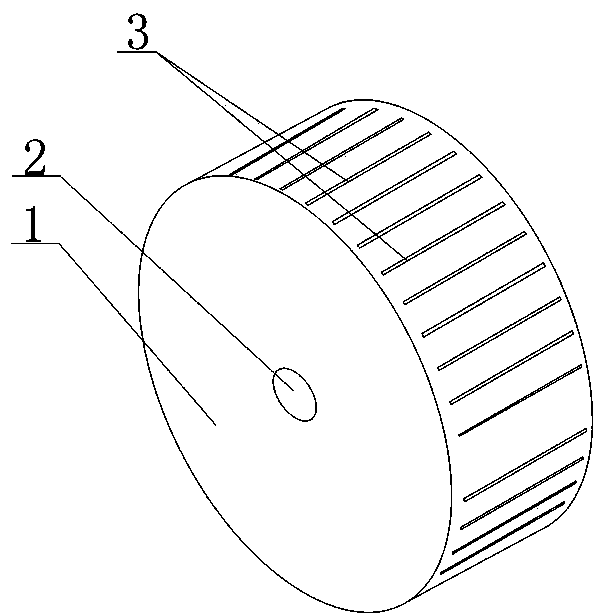

[0023] Such as Figures 1 to 3 As shown, the high-precision code wheel of the present invention includes a code wheel 1. The code wheel 1 is cylindrical, has two disc surfaces and a wheel surface connected between the disc surfaces, and is provided with a code wheel along the center of the disc. The through hole 2 of the axis is provided with as many code bars 3 as possible on the wheel surface. The code bars 3 are in a regular rectangle, and the code bars 3 are parallel to each other. For the wheel surface of the photoelectric encoder code wheel 1, there are Two surface treatment methods: the first one is to use chrome plating, gold plating or silver plating to treat the surface into a bright reflective surface; the second one is to use black matte treatment to form a low reflective surface; The code bar 3 is engraved on the wheel surface of the code wheel 1, and the engraving on the bright reflective surface appears as low-reflection stripes, and the engraving on the low-ref...

Embodiment 2

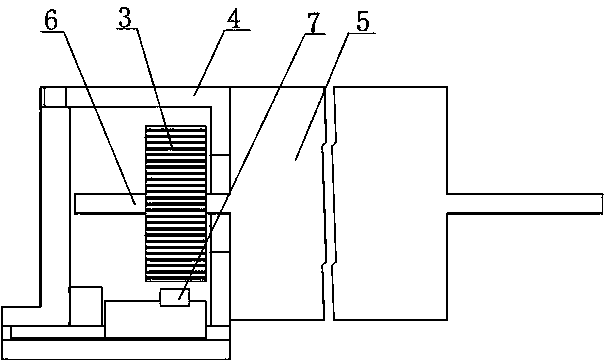

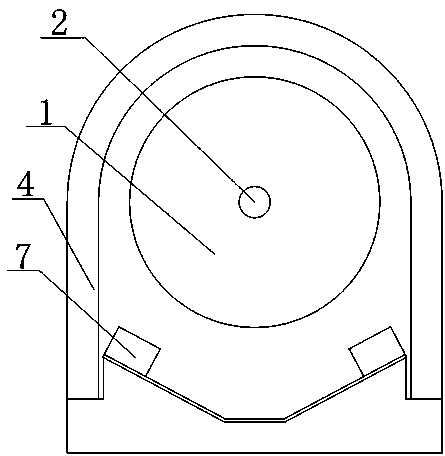

[0025] Such as Figures 4 to 5As shown, the high-precision encoder of the present invention includes a code wheel 1. The code wheel 1 is cylindrical and has two disc surfaces and a wheel surface connected between the disc surfaces. The through hole 2 of the axis is provided with a plurality of code strip rings containing as many code strips 3 as possible on the wheel surface. The code strips 3 are in a regular rectangle, and the code strips 3 are parallel to each other. Any two adjacent code strips The code bar 3 corresponding to the position on the ring is connected as a whole, the distance between the code bar 3 on a single code bar ring is the same, but the distance between the code bar 3 on different code bar rings is not the same, and press from left to The order of the right gradually shrinks. There are two surface treatment methods for the wheel surface of the photoelectric encoder code wheel 1 after polishing: the first method is to use chrome plating, gold plating or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com