Brewing assembly for an automatic hot-drink machine

A technology for vending machines and brewing rooms, which is applied in applications, home appliances, kitchen appliances, etc., and can solve problems such as difficulty for users to remove containers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

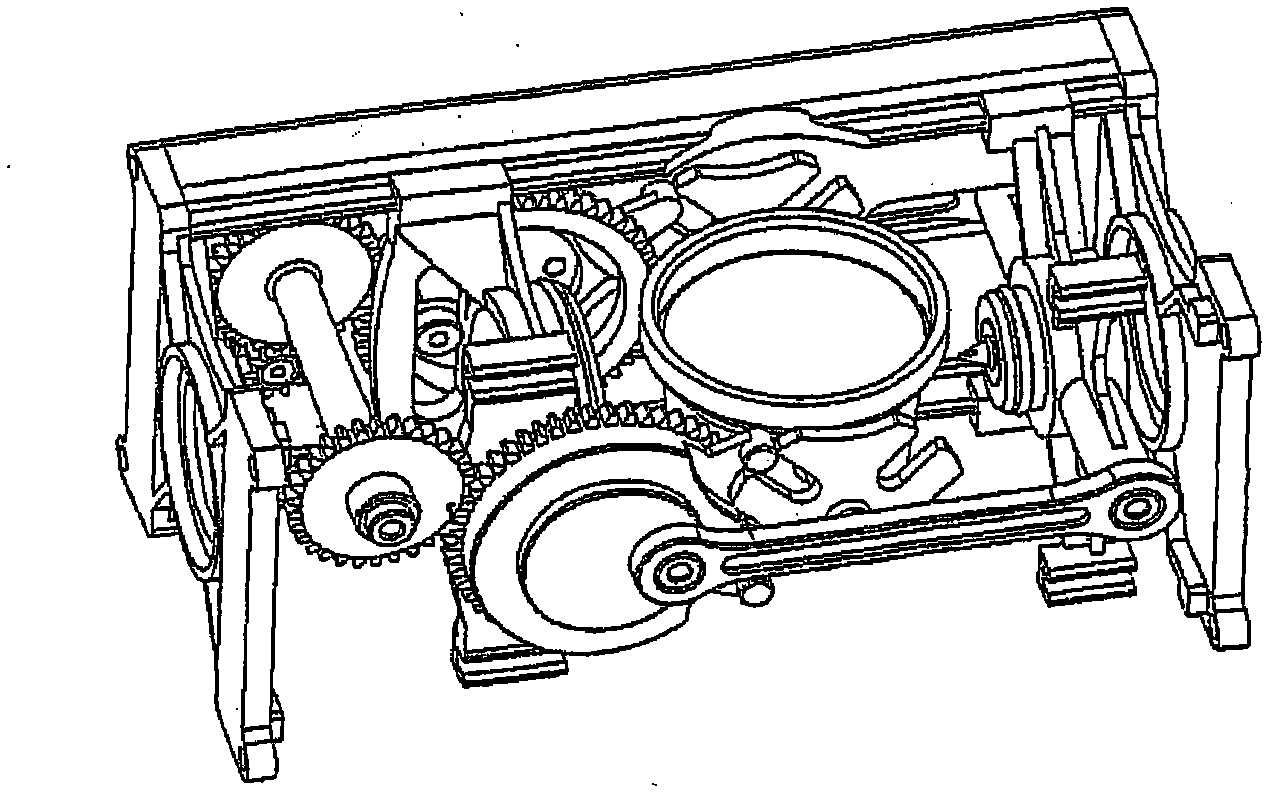

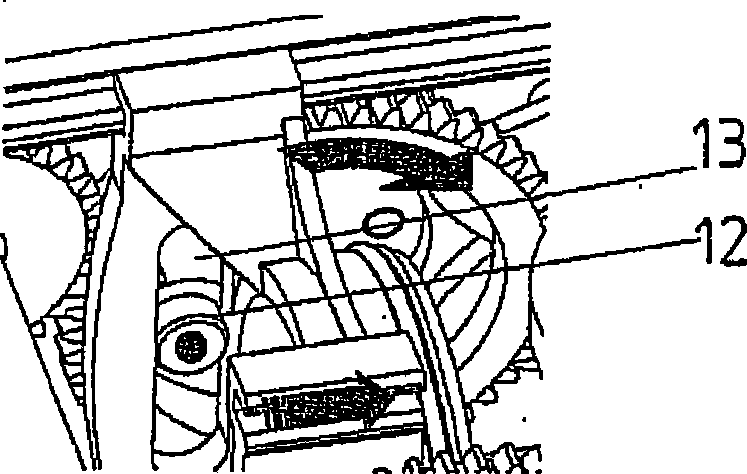

[0017] In order to simplify the handling of the beverage containers in the vending machine for the consumer, the design of the brewing unit of the vending machine includes an automatic container ejection device in a compact configuration. The design is mechanical and in the example a stepper motor is provided as drive.

[0018] In detail:

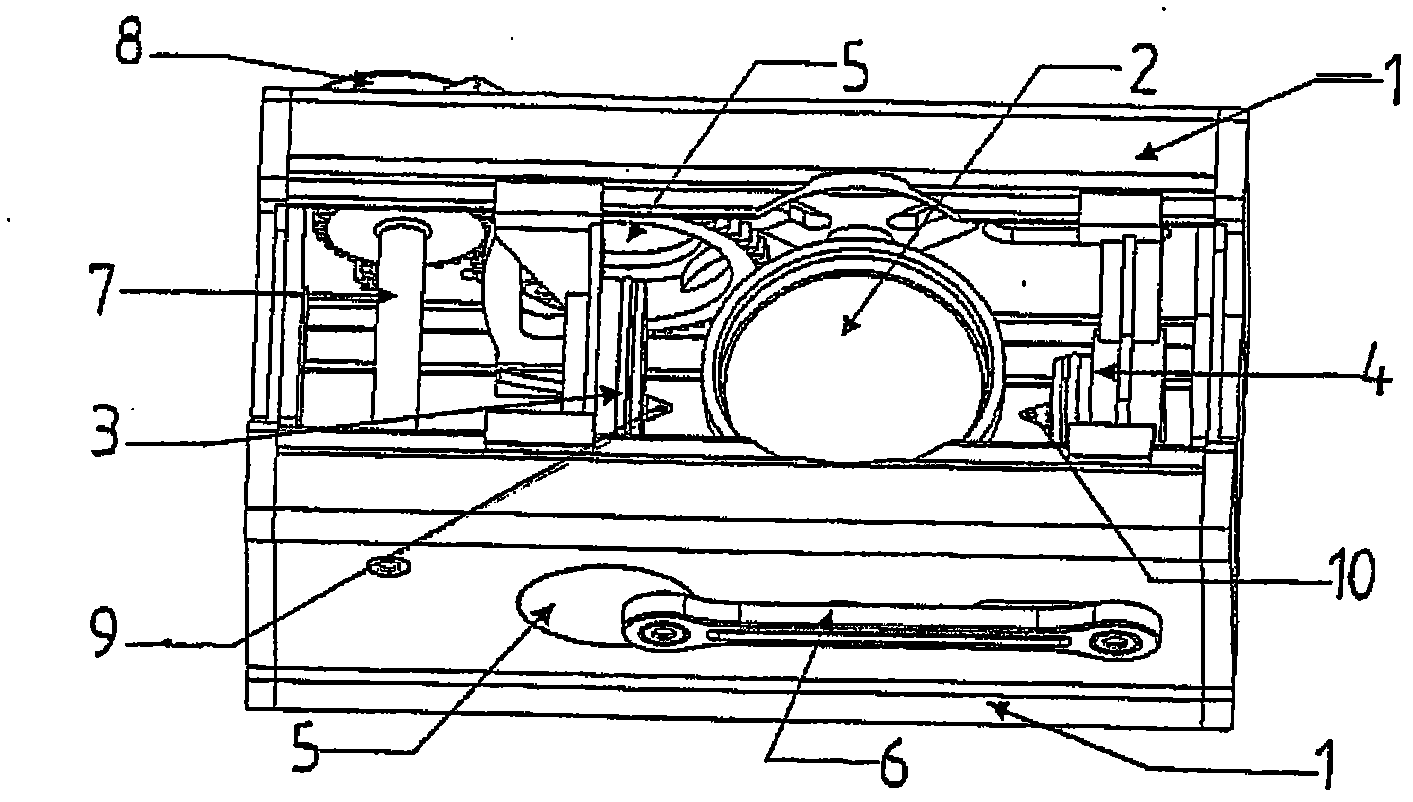

[0019] exist figure 1 , the basic elements of the brewing unit are shown. It comprises a housing 1 which, so to speak, forms or houses a brewing unit and completely encloses a brewing chamber. On the housing, indirectly rotatably mounted a container holder 2 which receives a beverage container during brewing. Further, closing parts are also provided, ie a first closing part 3 movable in the longitudinal direction of the central axis of the brewing chamber and a second closing part 4 movable in the same direction. This movement is achieved by means of two crank wheels 5 aligned coaxially with each other and connected to two connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com