Fuel injection valve

A technology for fuel injection valves and valve seats, which is applied in the direction of fuel injection devices, charging systems, engine components, etc. It can solve the problems of slow flow near the side, slow flow, and inability to effectively impart fuel vortex, so as to promote micro effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The fuel injection valve 1 of the first embodiment will be described.

[0043] [Structure of Fuel Injection Valve]

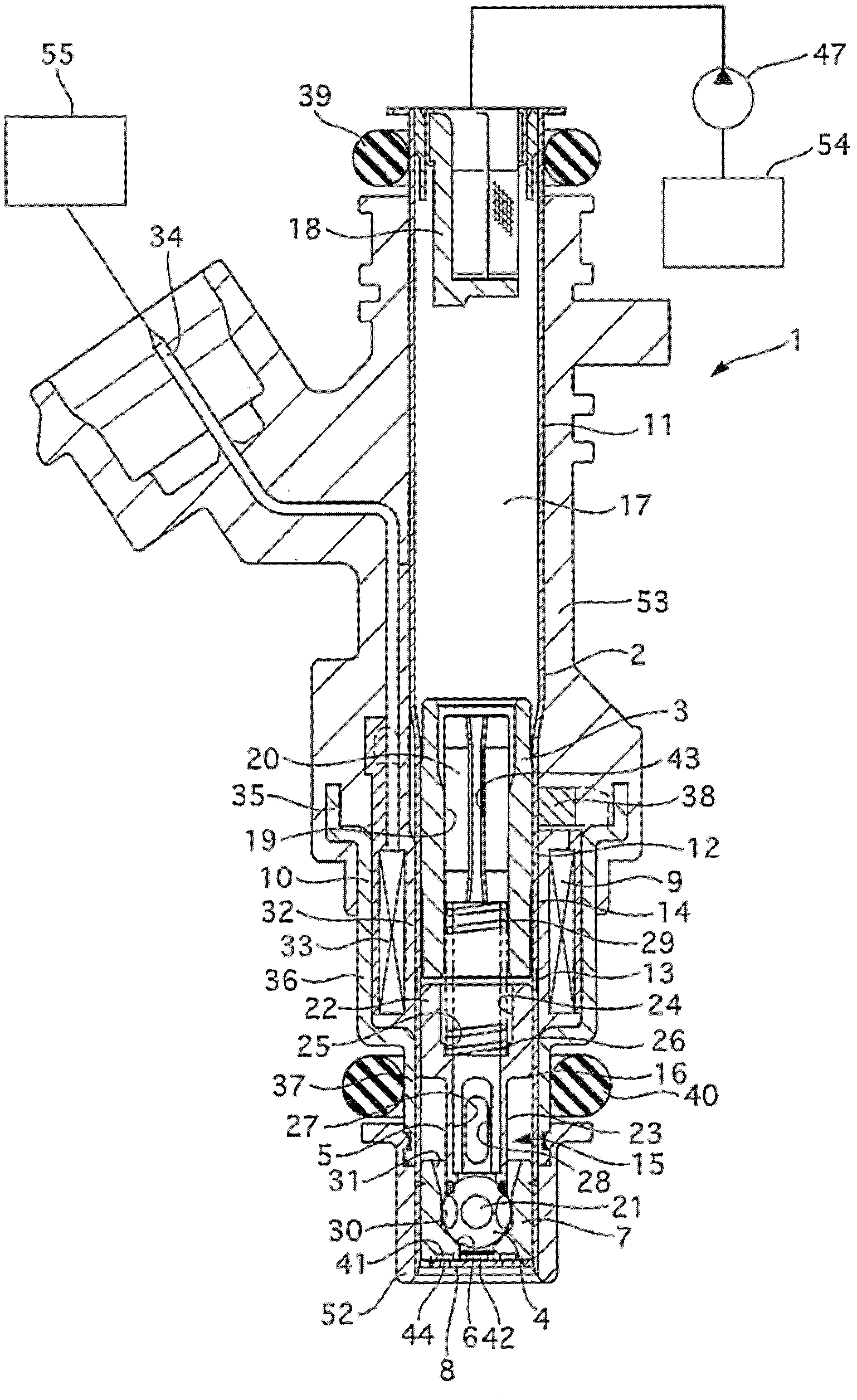

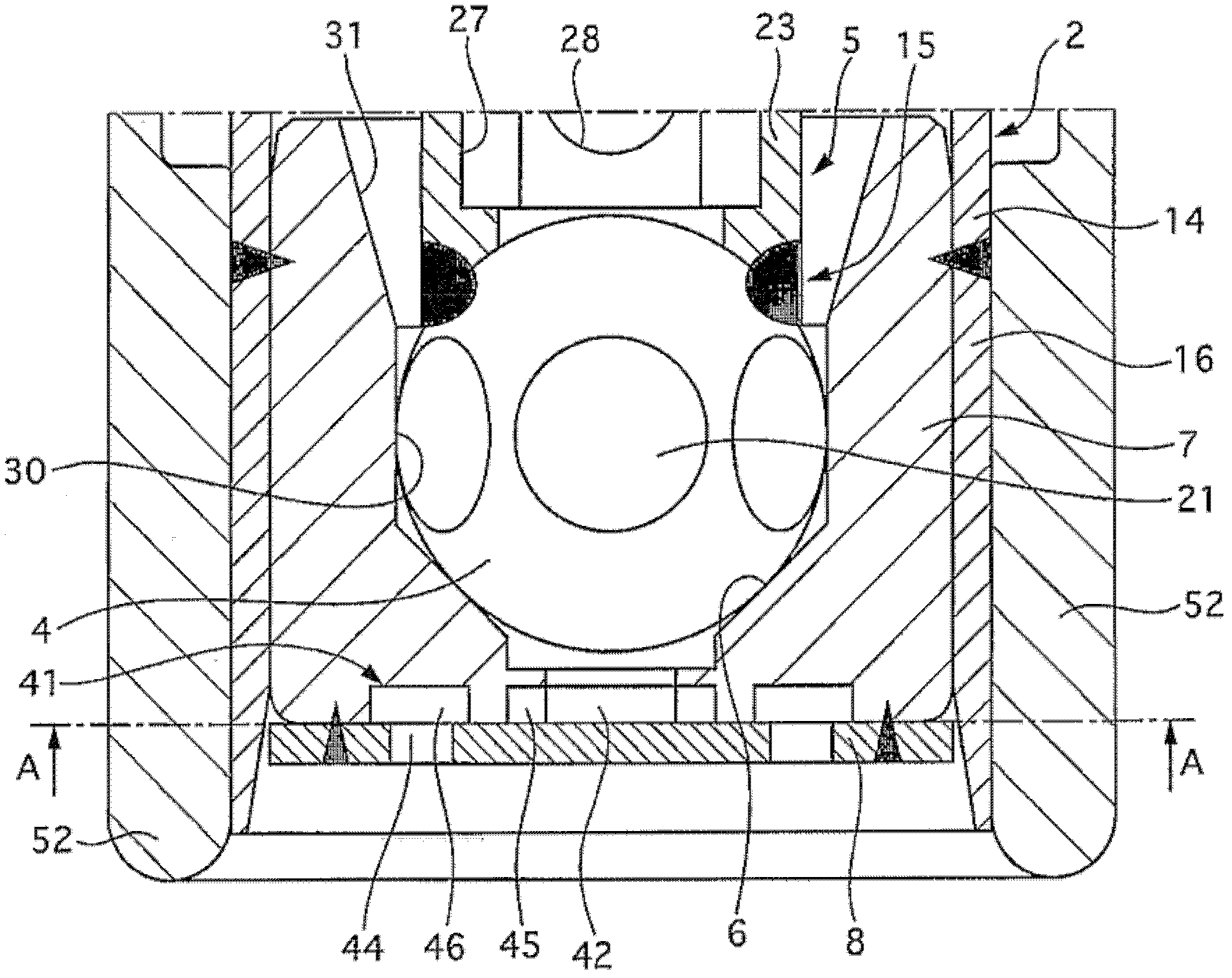

[0044] figure 1 is an axial sectional view of the fuel injection valve 1 . This fuel injection valve 1 is used in an automobile engine and the like.

[0045] The fuel injection valve 1 has: a magnetic cylinder body 2, a core cylinder body 3 housed in the magnetic cylinder body 2, a valve body 4 slidable in the axial direction, a valve shaft 5 integrally formed with the valve body 4, a The valve seat part 7 of the valve seat 6 which is blocked by the valve body 4, the nozzle plate 8 with the injection hole for injecting fuel when the valve is opened, the electromagnetic coil 9 which makes the valve body 4 slide in the valve opening direction when the valve is energized, and the sensor A yoke 10 for a magnetic induction line.

[0046] The magnetic cylinder body 2 is made of, for example, a metal tube formed of a magnetic metal material such as electroma...

Embodiment 2

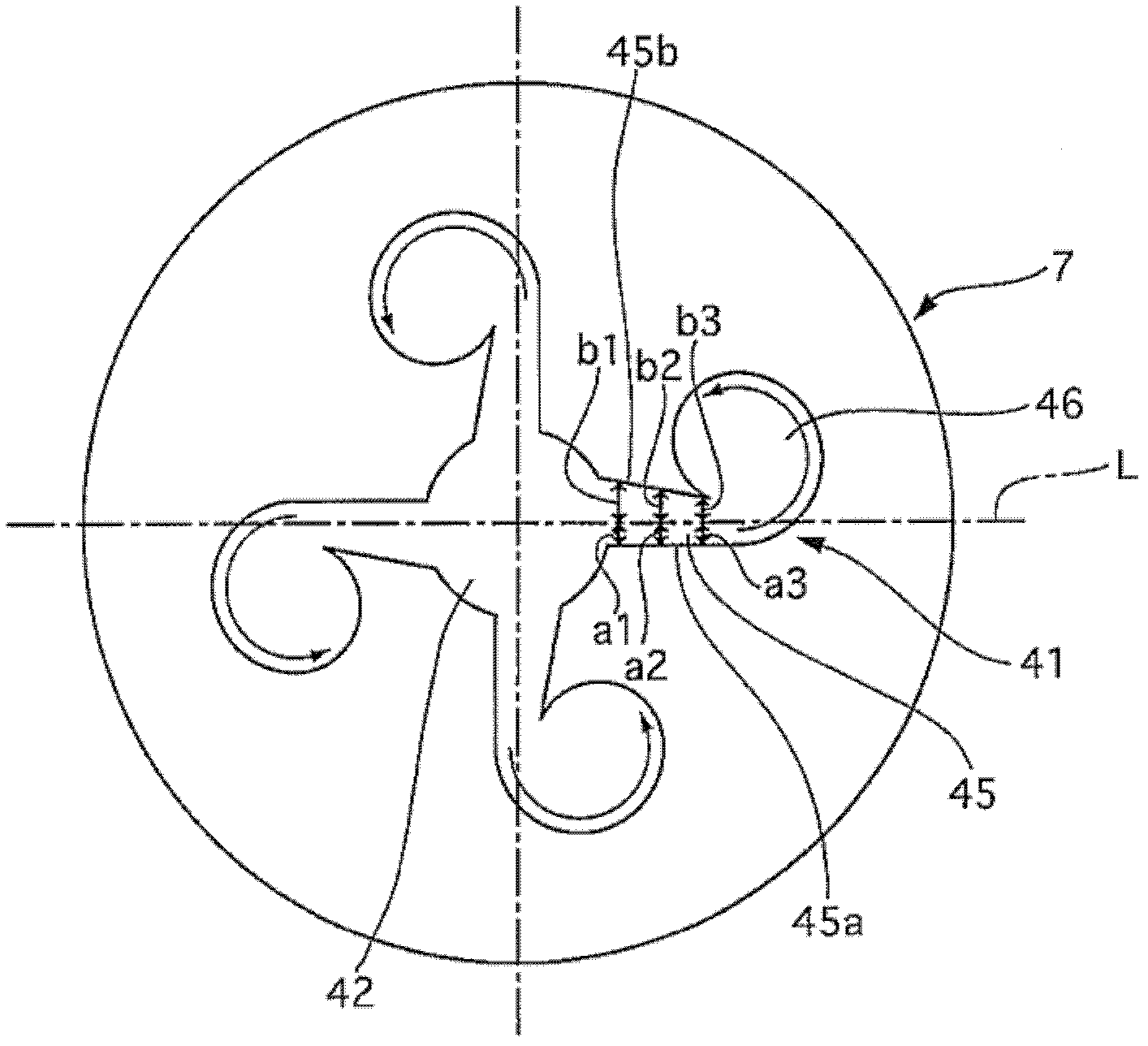

[0095] The fuel injection valve 1 of the second embodiment will be described. The same reference numerals are assigned to the same components as those of the fuel injection valve 1 of the first embodiment, and description thereof will be omitted. The shape of the communication passage 45 of the fuel injection valve 1 of the second embodiment is different from that of the fuel injection valve 1 of the first embodiment.

[0096] [Structure of Vortex Chamber]

[0097] Figure 11 It is a plan view of the valve seat member 7 seen from the other end side. The swirl chamber 41 is composed of a communication path 45 and a swirl imparting chamber 46 . The communication path 45 is formed to extend radially from the central chamber 42 . A swirl imparting chamber 46 is formed at the tip of the radially extending communication path 45 . As far as the swirl imparting chamber 46 is concerned, in Figure 11 In the plan view shown, the side wall is formed in an involute curved shape. Wh...

Embodiment 3

[0115] The fuel injection valve 1 of the third embodiment will be described. The same reference numerals are assigned to the same components as those of the fuel injection valve 1 of the first embodiment, and description thereof will be omitted. The shape of the communication passage 45 of the fuel injection valve 1 of the third embodiment is different from that of the fuel injection valve 1 of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com