High-speed visual positioning device and method applied to substrate

A visual positioning and visual device technology, which is applied in the direction of using optical devices, measuring devices, lighting devices, etc., can solve the problems of non-positioning, skewed board, and large variation of manual board operation efficiency, so as to improve the accuracy and artificial intelligence. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention proposes a high-speed visual positioning device and method suitable for substrates, which can be used to quickly move substrates, such as strip-shaped modules of light-emitting diodes, to solve the problem that traditional machines cannot be used for strip-shaped light-emitting diodes. Shaped modules, so the production unit can be manufactured for the purpose of improving production efficiency.

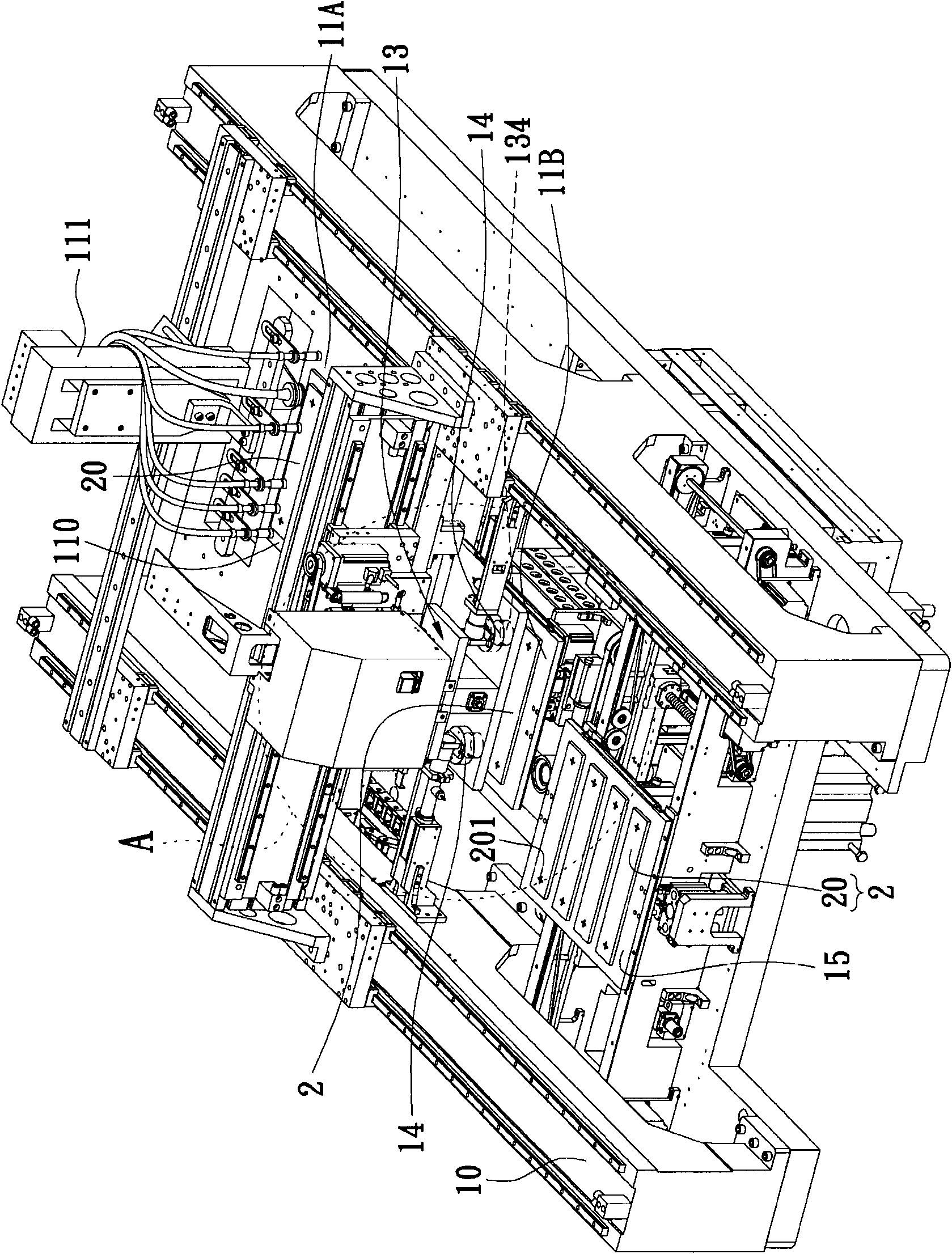

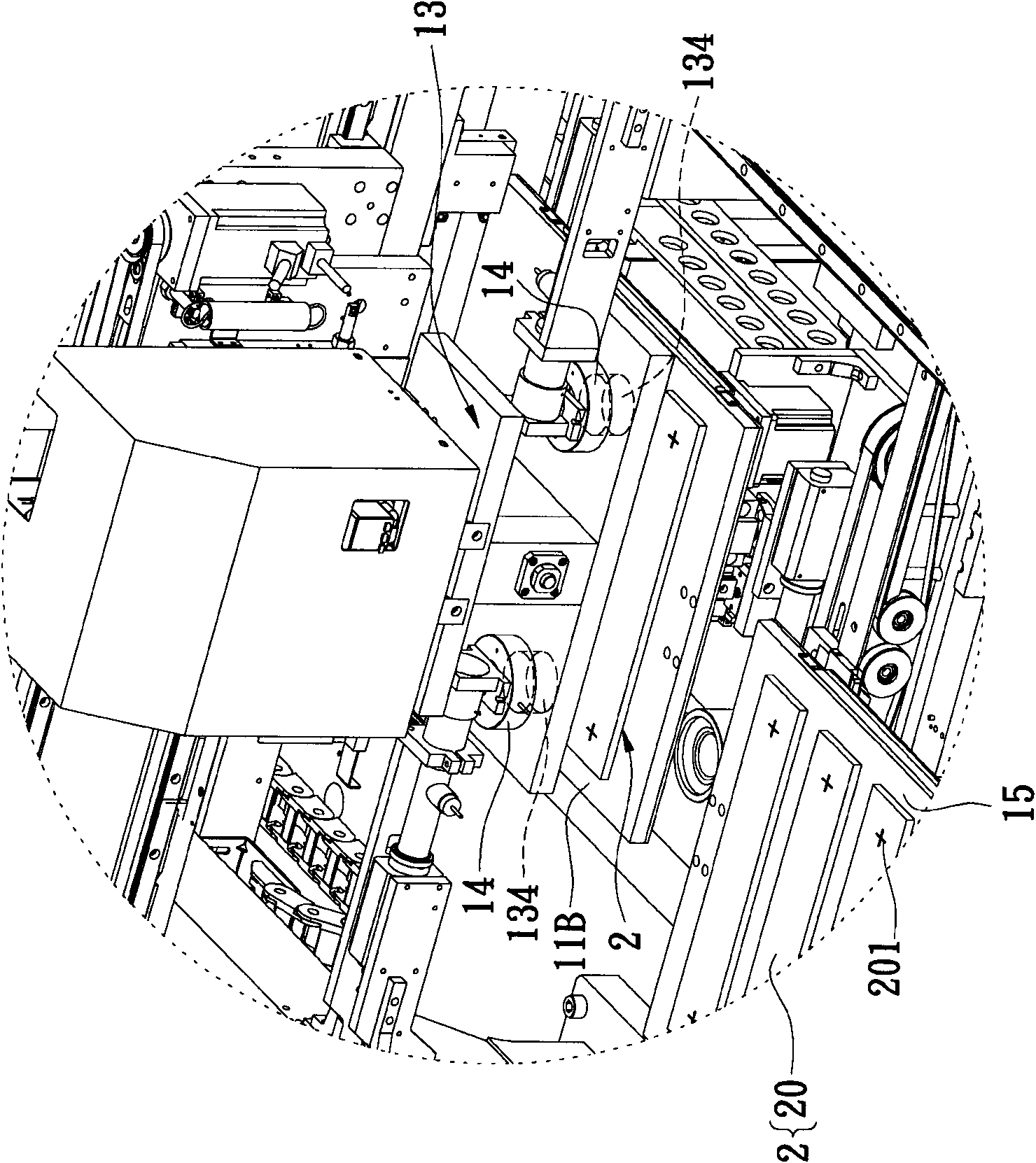

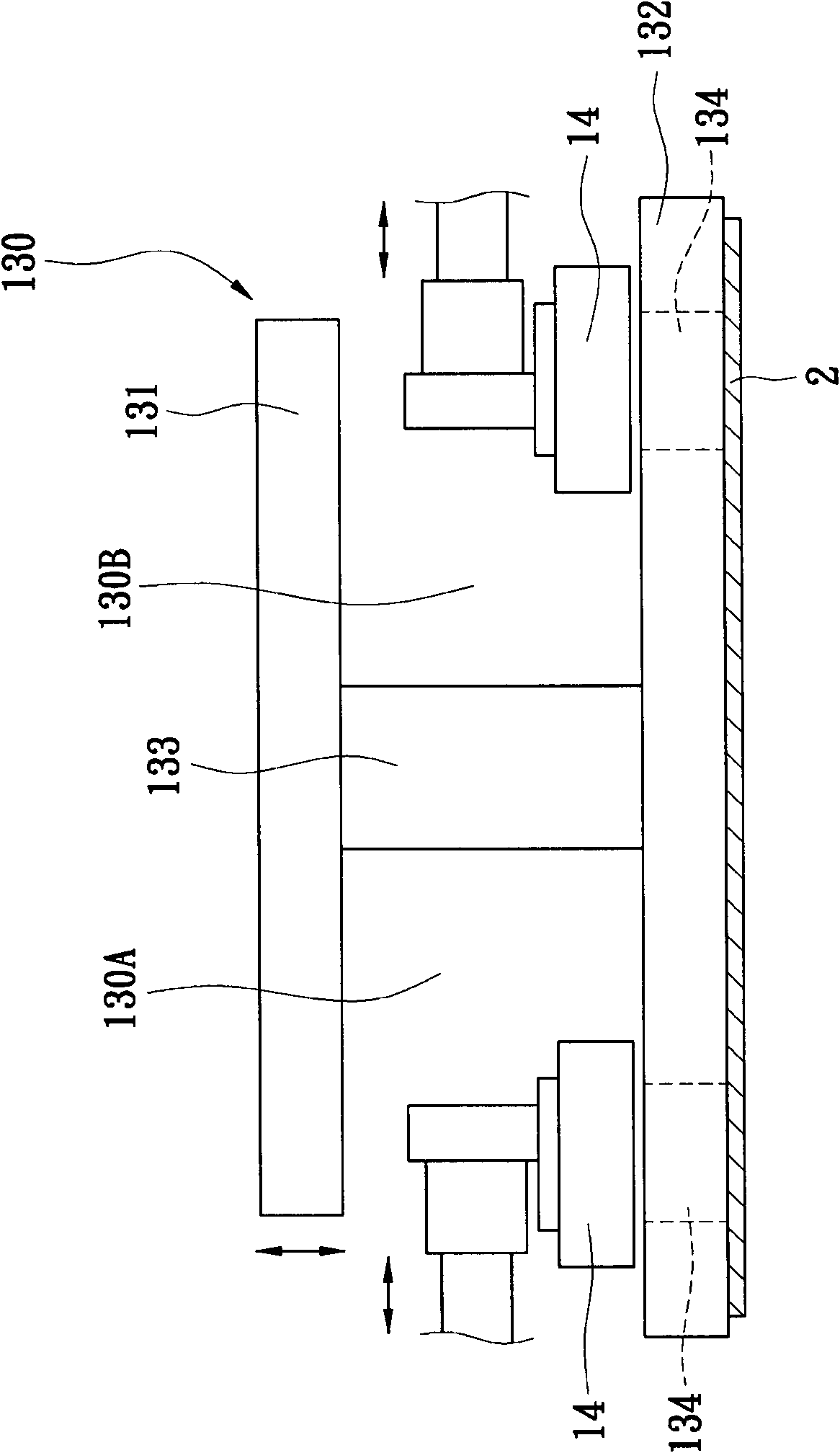

[0034] First, see Figure 1 to Figure 1B As shown, the visual positioning device of the present invention includes: a frame body 10, a temporary storage area 11A located on the frame body 10, a positioning area (also known as a material retrieval area) 11B located on the frame body 10, a moving Positioning device 13, at least two visual devices 14 arranged on the frame body and a carrier plate 15 placed on the frame body 10, and the function of the visual positioning device is to place a plurality of substrates, such as strips of light emitting diodes Mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com