Fuse

A fuse and housing technology, applied in the field of fuses, can solve problems such as arc phenomenon, danger of use, breakage, etc., and achieve the effect of avoiding arc phenomenon and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

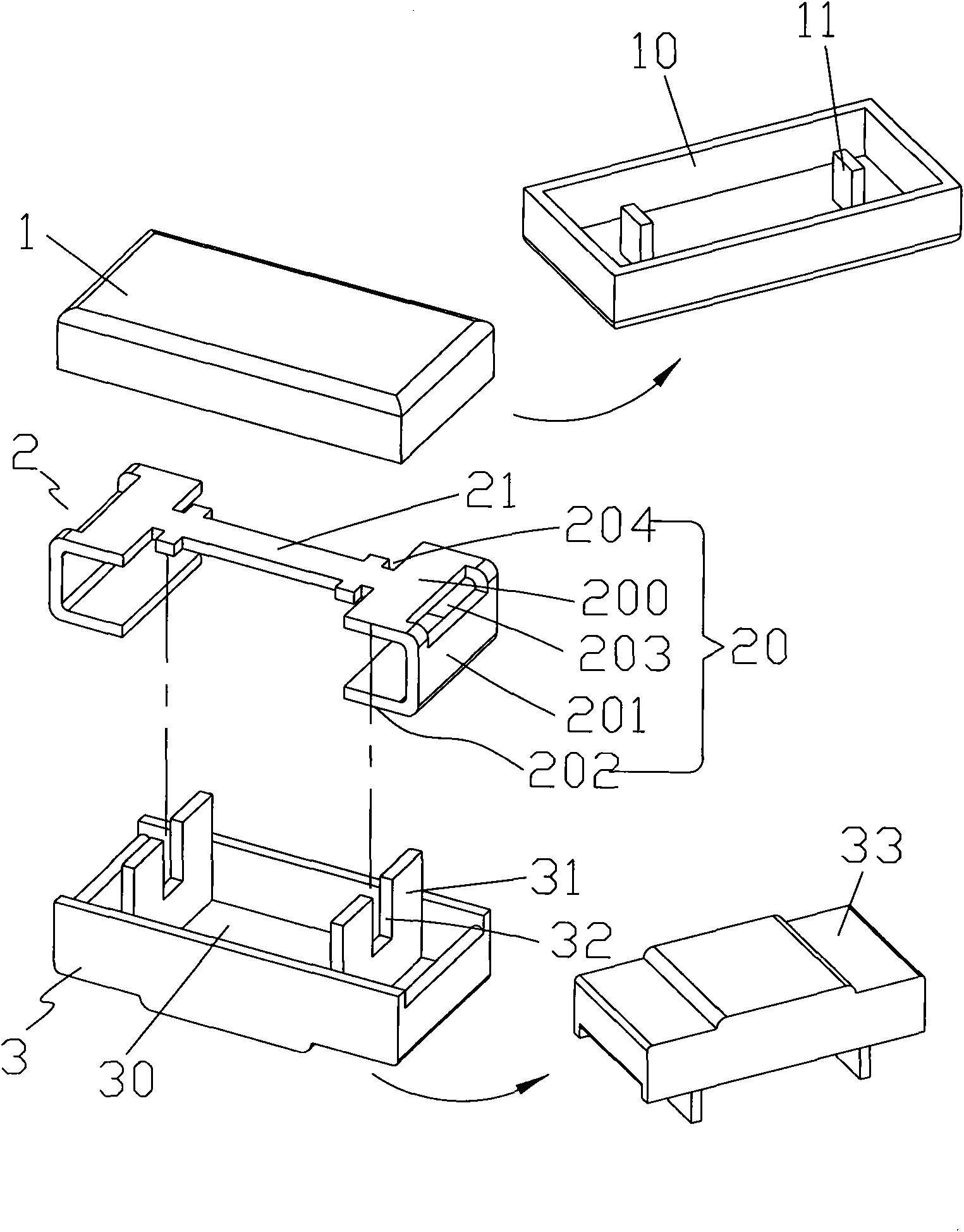

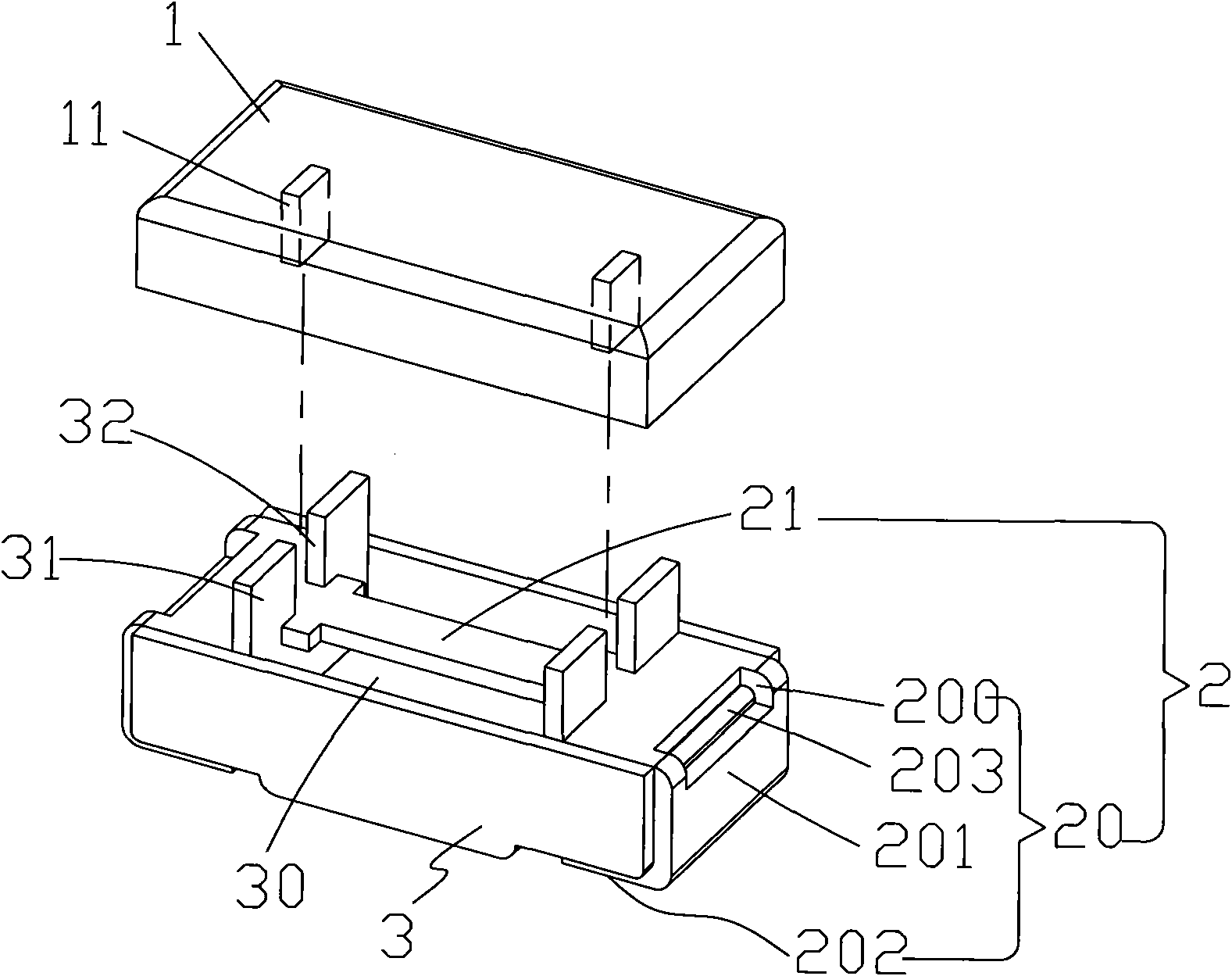

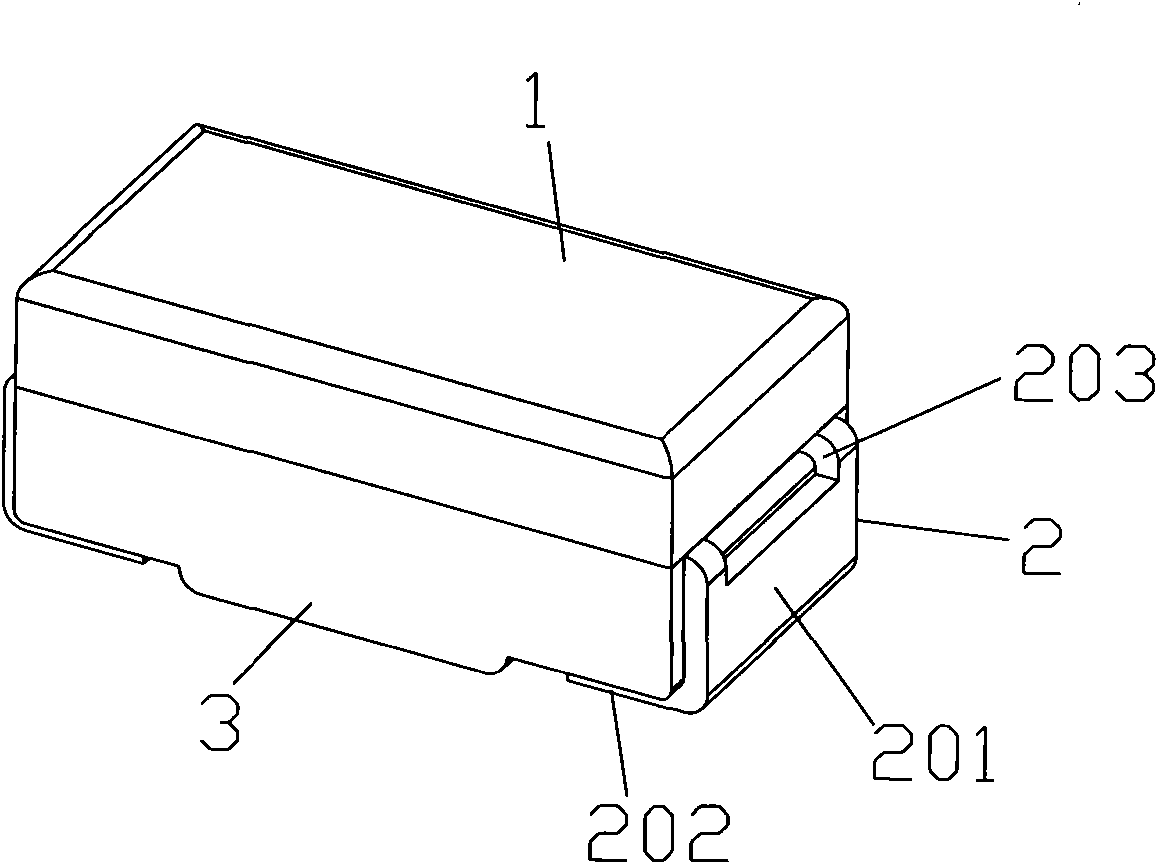

[0030] Please cooperate with reference figure 1 As shown, the first embodiment of the fuse of the present invention has a first housing 1 , a disconnecting device 2 and a second housing 3 .

[0031] One side of the first casing 1 has a first accommodating groove 10 , and there are two pressing columns 11 in the first accommodating groove 10 , and the pressing columns 11 are opposite to each other.

[0032] The disconnecting device 2 has two electrodes 20 and a fuse portion 21. Each electrode 20 has a first sheet 200, a side sheet 201 and a second sheet 202. One side of the first sheet 200 and the side sheet 201 are connected to each other, and a gap 203 is formed between the junction of the first sheet 200 and the side sheet 201, the other side of the side sheet 201 is connected to the second sheet 202, and the other side of the first sheet 200 One side is formed with two opposite locking notches 204 , and each electrode 20 is integrally formed to form an inverted U-shaped st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com