Fixed contact

A static contact and cylinder technology, applied in the field of electric equipment accessories, can solve the problems of affecting the safety of high-voltage power distribution, reducing the service life, and easy damage of static contacts, so as to achieve reasonable structure, prolong service life and prevent arcing The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

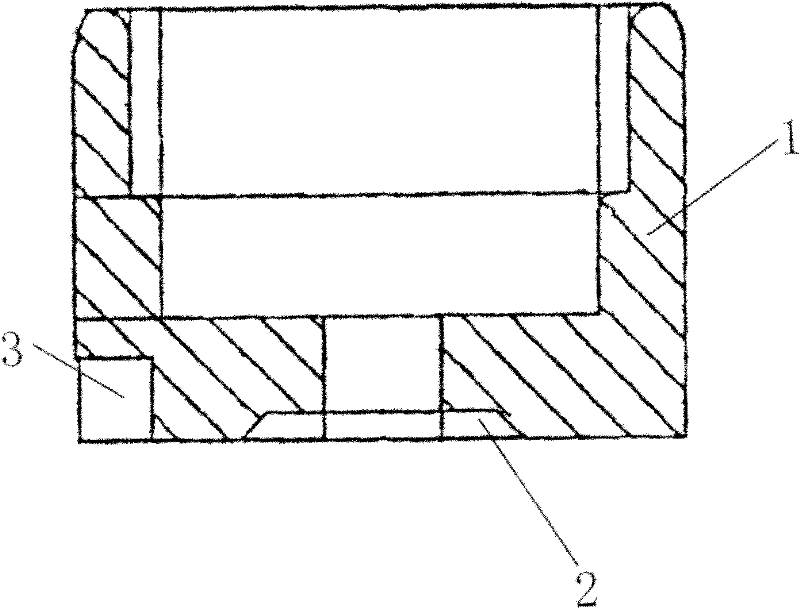

[0013] Embodiment 1: as figure 1 As shown, a static contact includes a hollow cylindrical cylinder 1, the inner wall thickness of the cylinder 1 is divided into three stages from top to bottom in a stepped manner, and the inner and outer sides of the upper edge of the cylinder 1 All are provided with chamfering, and an installation hole 2 communicating with the inner cavity of the cylinder 1 is opened at the bottom of the cylinder 1; a gap 3 is provided outside the bottom of the cylinder 1; the inner wall thickness of the cylinder 1 from top to bottom is 20cm, 31cm, 58cm; on the entire cylinder 1, the cylinder 1 with a wall thickness of 20cm has a height of 32cm and an inner diameter of 89cm; the cylinder 1 with a wall thickness of 31cm has a height of 21cm and an internal diameter of 78cm; the cylinder with a wall thickness of 58cm Body 1 has a height of 22cm and an inner diameter of 21cm; the diameter of mounting hole 2 is 51cm; the chamfer on the outside of the upper edge i...

Embodiment 2

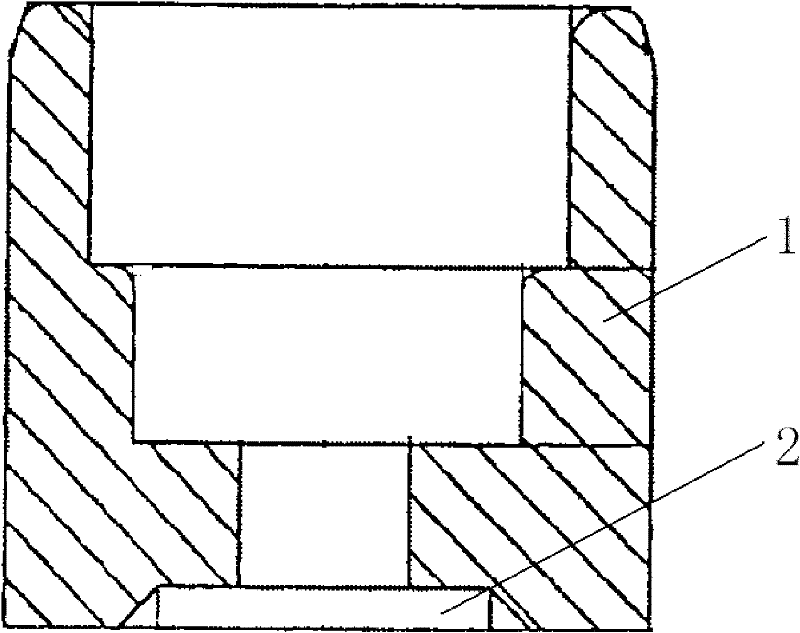

[0014] Embodiment 2: as figure 2 As shown, a static contact includes a hollow cylindrical cylinder 1, the inner wall thickness of the cylinder 1 is divided into three stages from top to bottom in a stepped manner, and the inner wall thickness of the cylinder 1 is divided into three stages, from From top to bottom, they are 20cm, 31cm, and 88cm; on the entire cylinder 1, the cylinder 1 with a wall thickness of 20cm has a height of 32cm and an inner diameter of 59cm; the cylinder 1 with a wall thickness of 31cm has a height of 21cm and an inner diameter of 48cm; The cylinder 1 with a thickness of 58cm has a height of 22cm and an inner diameter of 21cm; the diameter of the installation hole 2 is 51cm; the chamfer on the outside of the upper edge is 15°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com