Method for inspecting an austenitic stainless steel weld

A technology for austenitic stainless steel and inspection coils, applied in instruments, measuring devices, material analysis through electromagnetic means, etc., can solve problems such as delta-ferrite errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

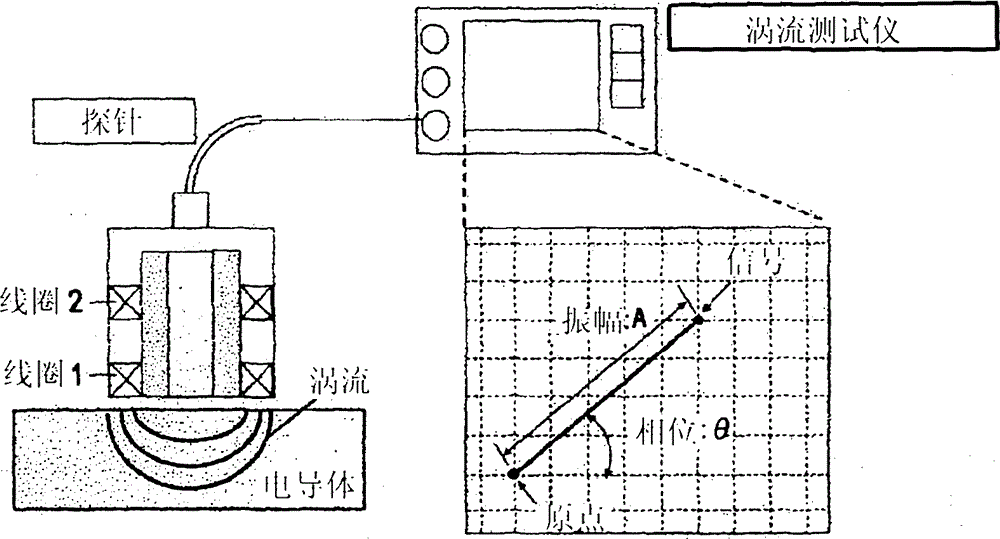

[0048] Use the probe, eddy current tester and recorder as follows. (1) Probe

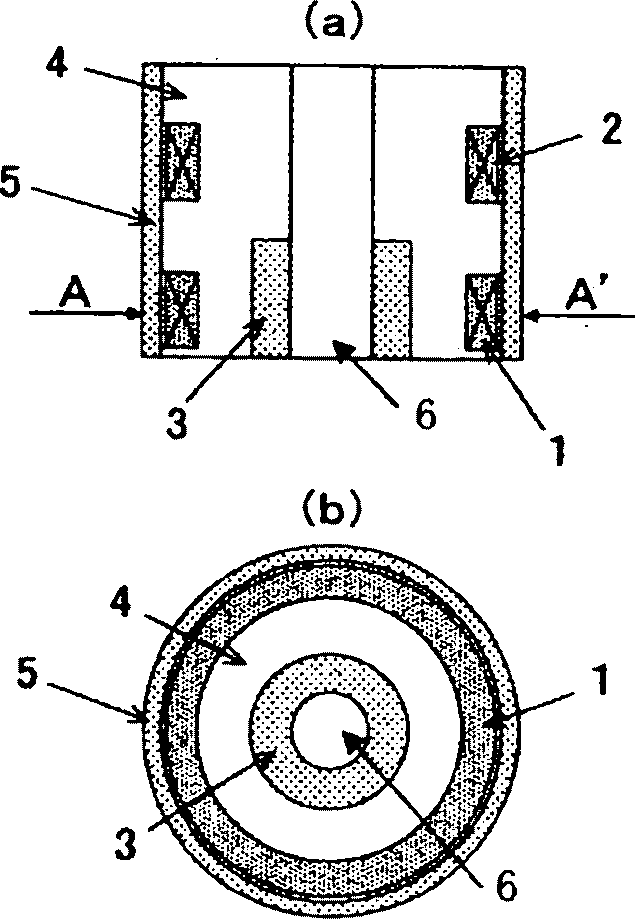

[0049] preparation and use image 3 The same probes shown in . The materials and shapes used are shown below.

[0050] Excitation and inspection coil 1 and balance coil 2: outer diameter 28mm x inner diameter 21mm x length 8mm, and copper wire diameter 0.16mm x turns 500

[0051] Permanent magnet 3: Outer diameter 18mm×inner diameter 12mm×thickness 1.8mm×8 pieces

[0052] Neodymium magnet -32H (manufactured by Sumitomo Special Metals. Co., Ltd.)

[0053] Magnetic flux density of the magnetic field formed by this permanent magnet: about 0.5 Tesla

[0054] Spool: polyacetal copolymer (manufactured by Polyplastics Co., Ltd.)

[0055] Magnetic Shield: Carbon Steel

[0056] Shell: polyacetal copolymer

[0057] Adhesive for fixing: Acrylic Adhesive Hard (Made by DENKI KAGAKU KOGYO KABUSHIKI KAISHA)

[0058] (2) Eddy current tester:

[0059] Eddy Current Tester MiniPhasec (manufactured by GE ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com