Double drive end effector for plug seedling pot transplanting system

An end-effector and dual-drive technology, which is applied in transplanting machinery, applications, agriculture, etc., can solve the problems that affect the success rate of pot transplanting and the function of the end effector is not good enough, so as to reduce incomplete separation and improve the success of pot transplanting rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

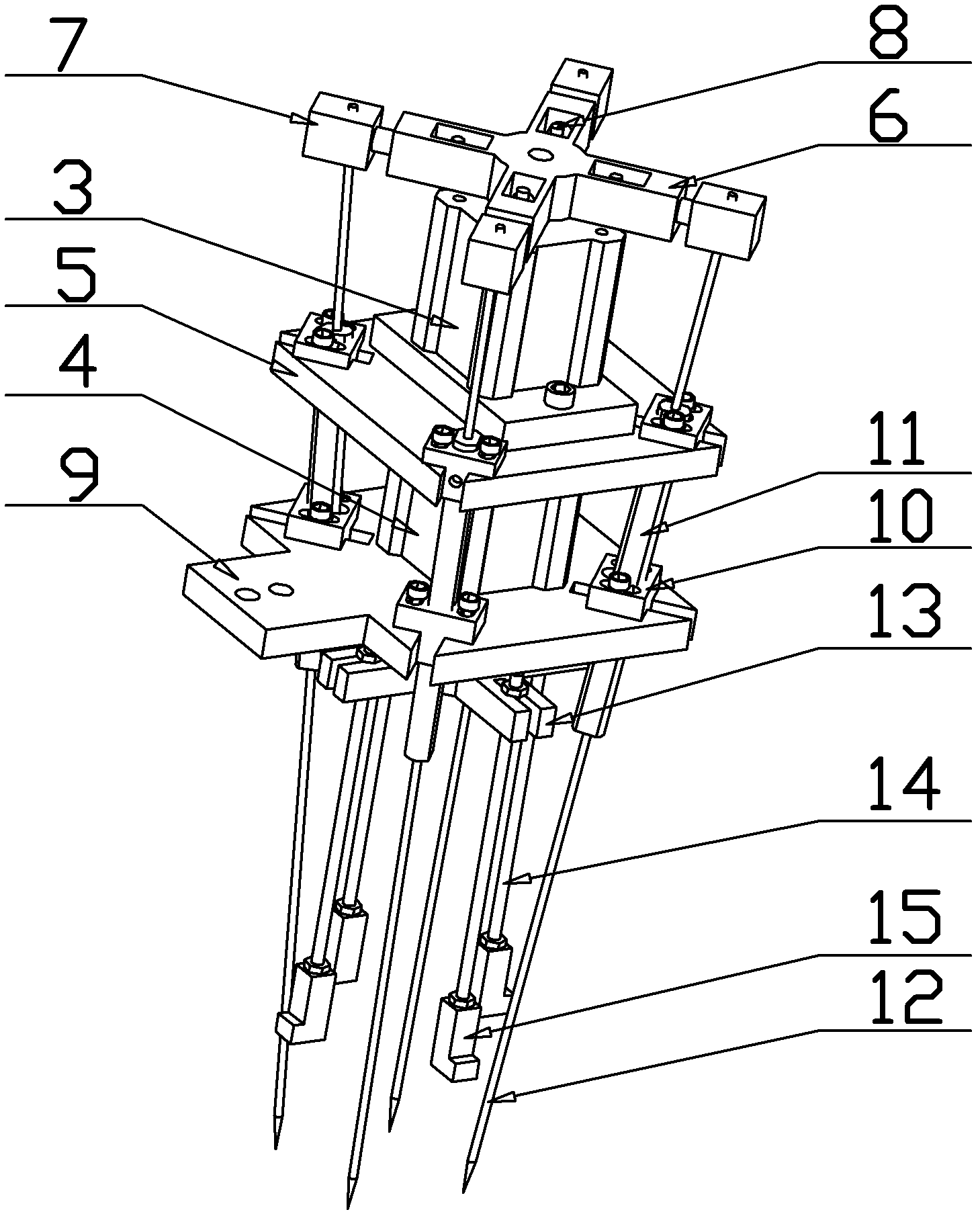

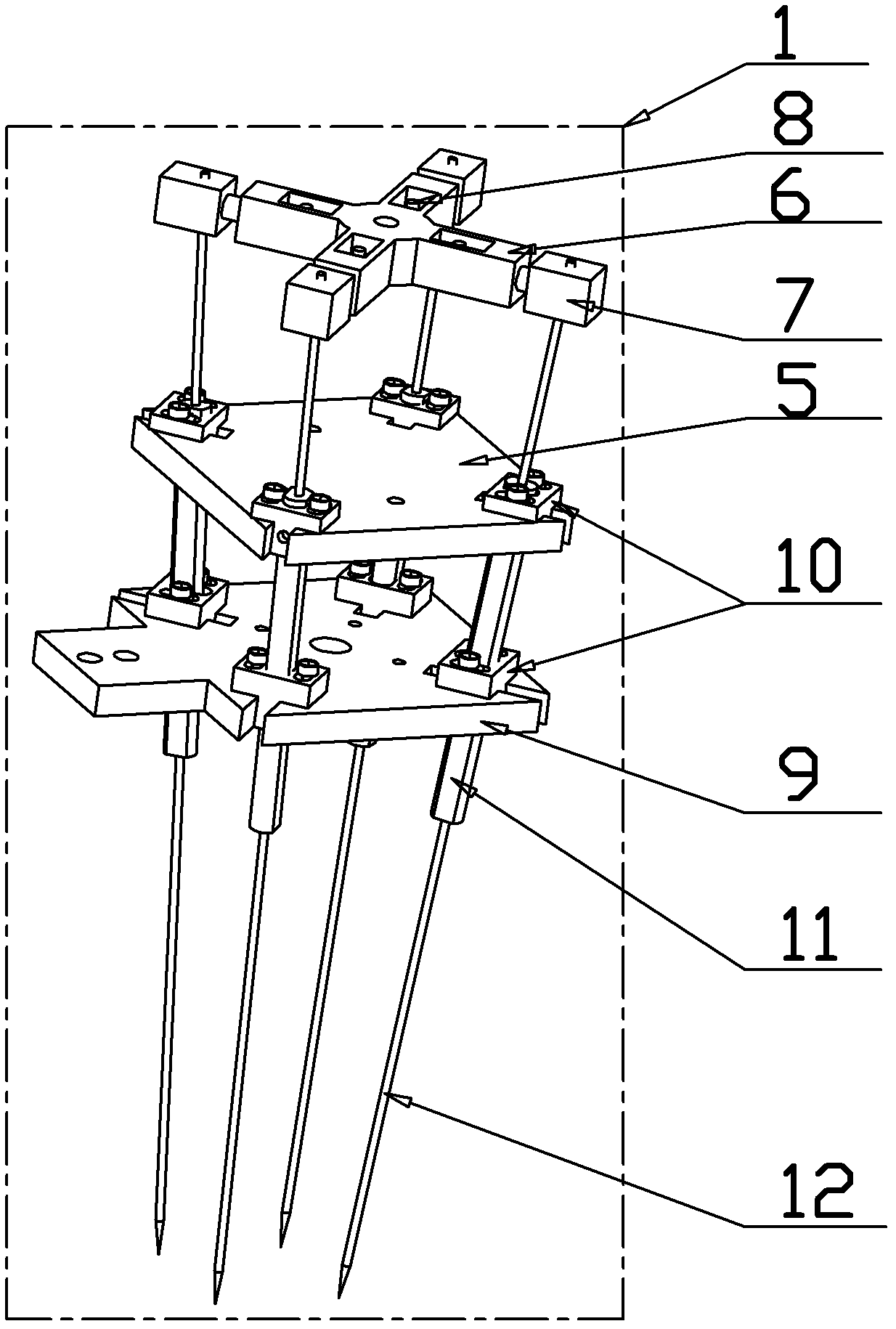

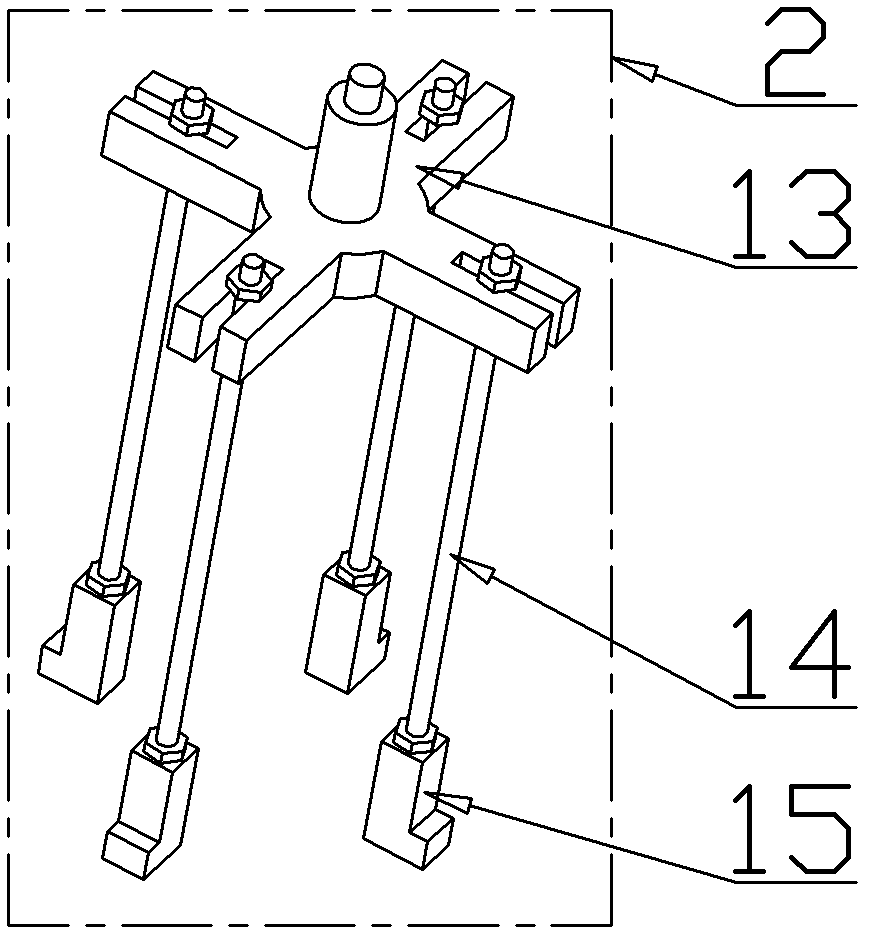

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the present invention includes a seedling-taking executive part 1, a seedling-picking executive part 2, a seedling-picking cylinder 3 and a seedling-picking cylinder 4; On the top, the cylinder rod of the seedling-taking cylinder 3 faces up and is fixed with the center hole of the variable-distance cross force frame 6, and the seedling-taking needle fixing member 7 is inserted into the four arms of the variable-distance cross force frame 6 and locked with pins 8 respectively. , the seedling-taking needle fixing part 7 forms sliding fit respectively with the 6 four arms of the variable-pitch cross force frame; Go down and pass through the seedling-picking cylinder fixed plate 9 and connect with the central rod of the seedling-picking executive part 2; Get the seedling cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com