End effector of a plug seedling pot transplanting system

An end effector and plug seedling technology, which is applied in the field of end effectors of plug seedling transplanting systems, can solve the problems of complex structure, limited types of transplanted crops and plug tray specifications, and achieves the effect of avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

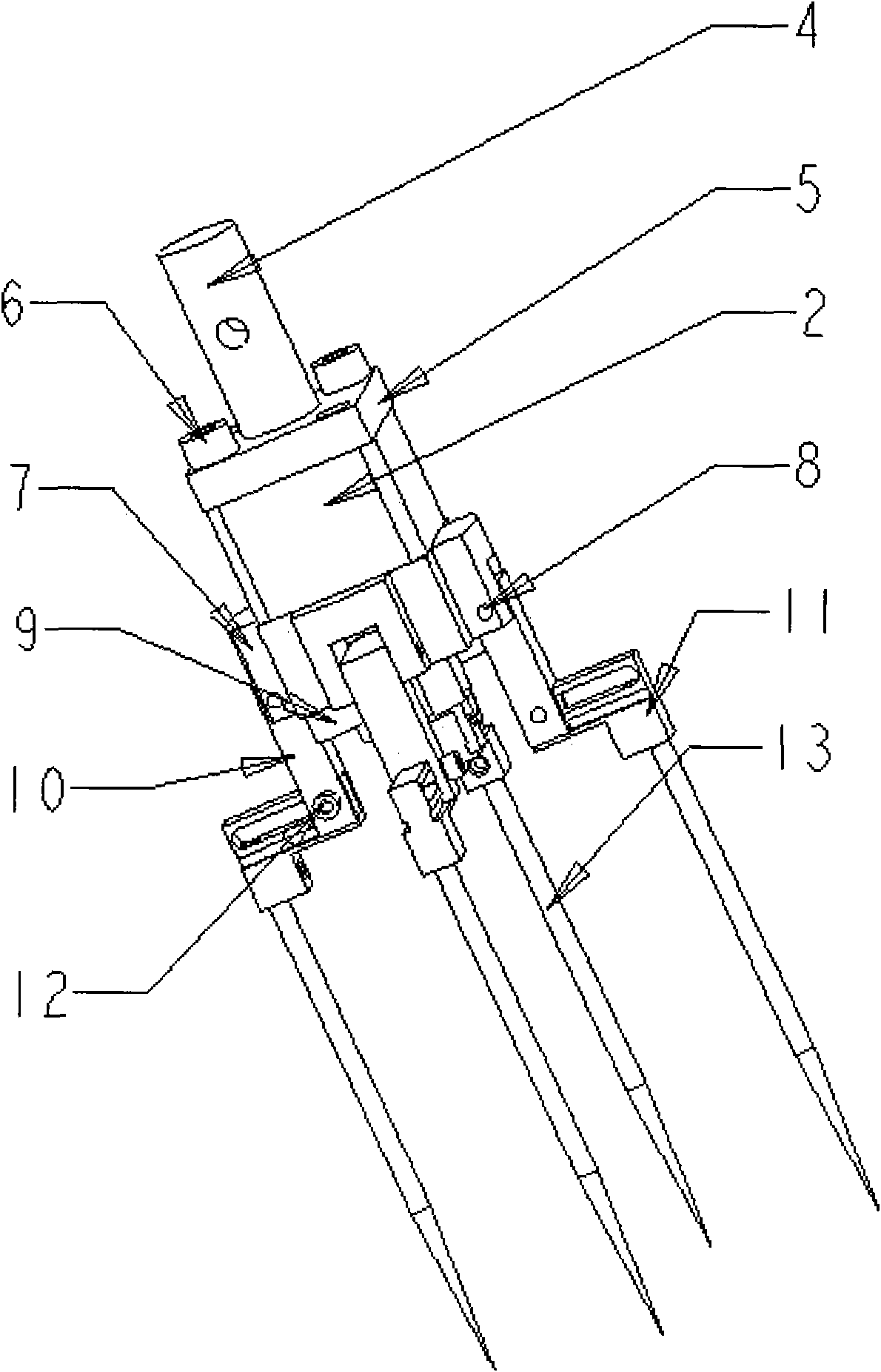

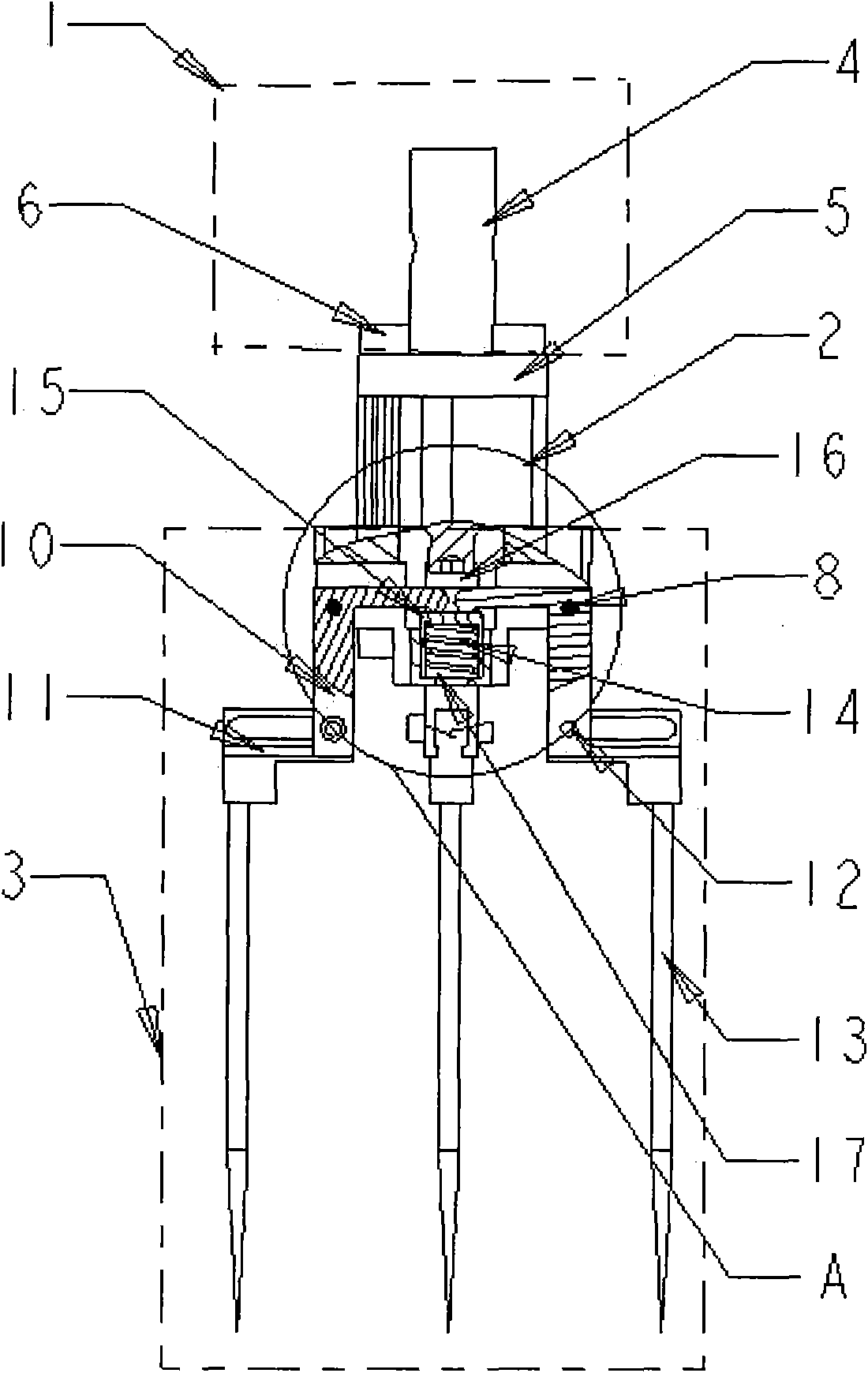

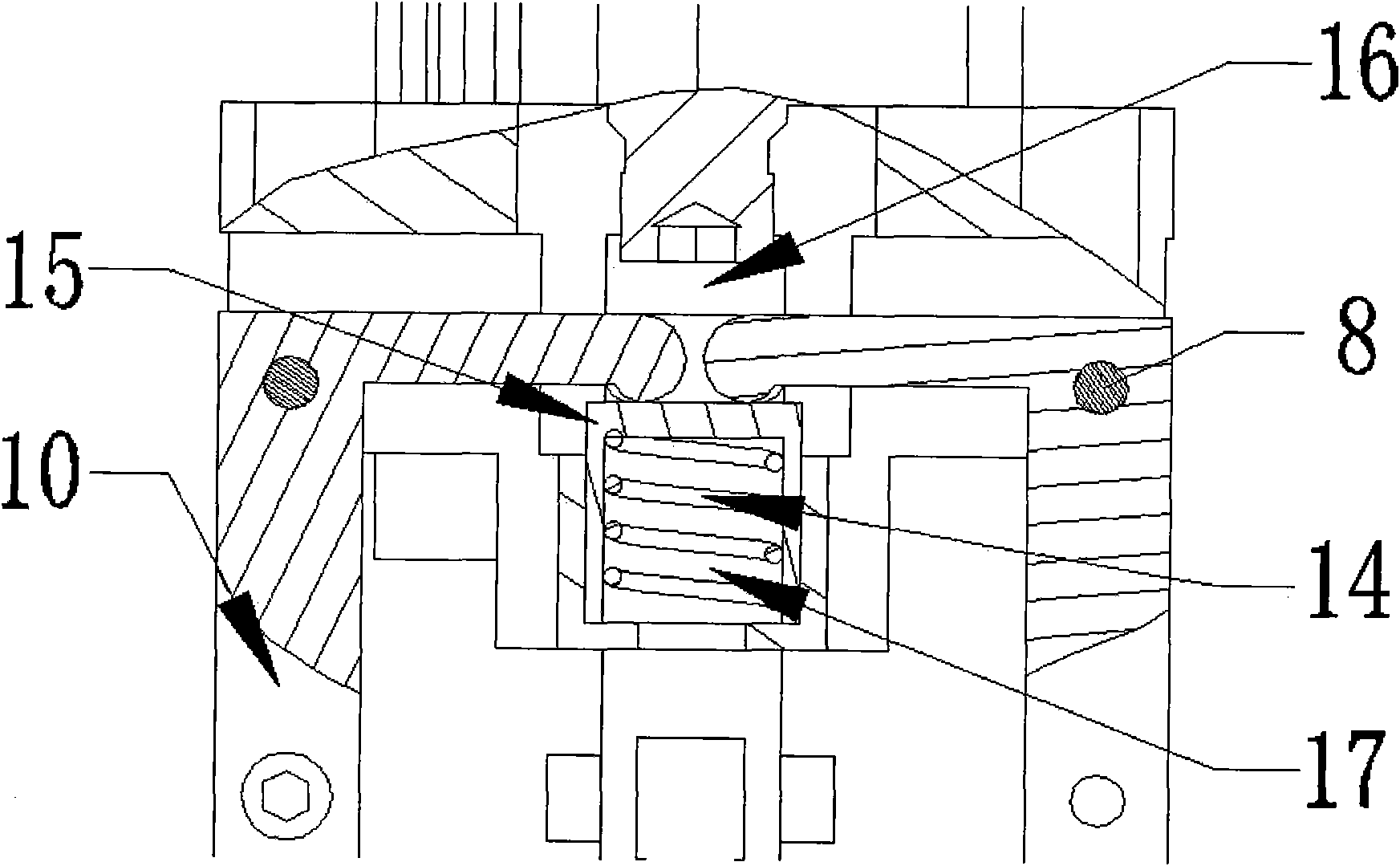

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the present invention includes an end effector connection part 1, a linear cylinder 2 and a grasping execution part 3; the upper end surface of the linear cylinder 2 is connected with the connecting plate 5 of the end effector connection part 1, and the lower end surface of the linear cylinder is connected with the grasping The execution body frame 7 of the execution part 3 is connected. The end effector connecting part 1: includes a connecting rod 4 and a connecting plate 5; the connecting rod 4 is installed in the center of the connecting plate 5. Grab the execution part 3: including the execution body frame 7, four inverted L-shaped rocker arms 10, the same number of inverted L-shaped finger connecting sliders 11 as the inverted L-shaped rocker arms 10, two or four needle fingers 13. The return spring 14 and the spring pressing block 15; the center of the actuator frame 7 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com