Magnetic printing mother set, preparation method thereof and preparation equipment

A technology of magnetic printing and manufacturing method, applied in the directions of printing plate preparation, printing, printing plate, etc., can solve the problems such as the inability of the magnetic printing master to produce the combination of magnets and the inability to obtain the effect of optically variable patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

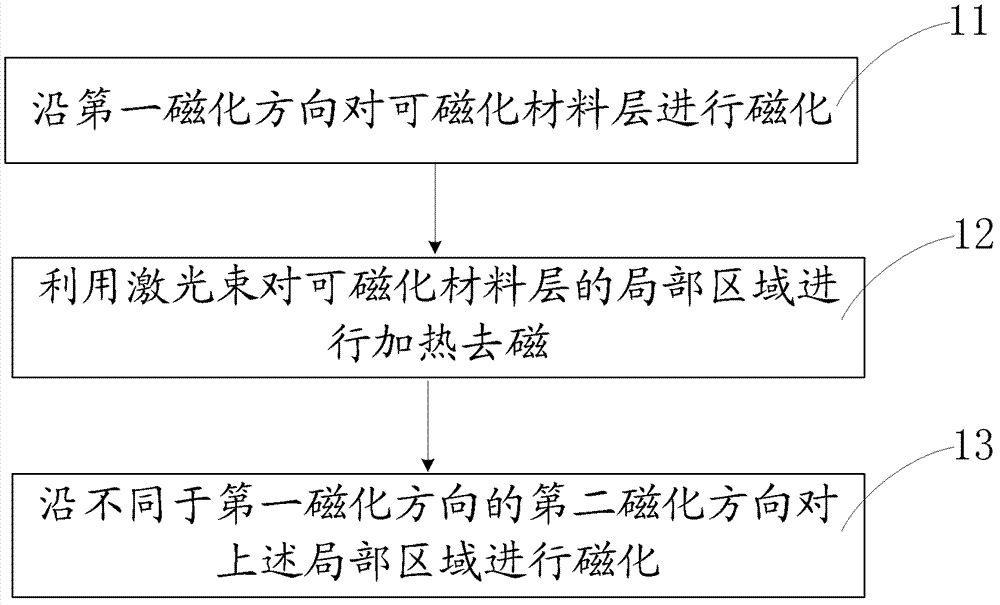

[0017] See figure 1 and Figure 2a-2e , figure 1 is a flowchart of a method for manufacturing a magnetic printing master according to a first embodiment of the present invention, Figure 2a-2e yes figure 1 Schematic representation of the different steps of the fabrication method shown. Such as figure 1 and Figure 2a-2e As shown, the manufacturing method of the magnetic printing master in this embodiment includes the following steps.

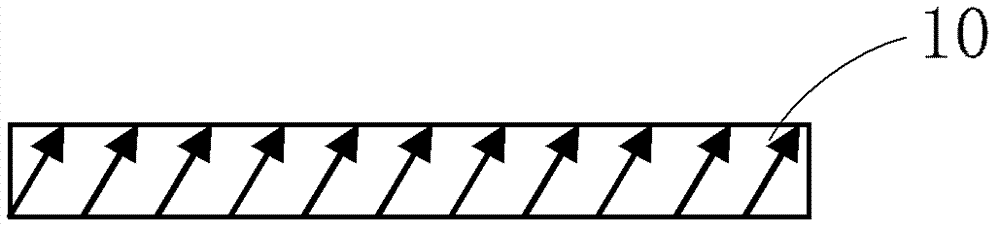

[0018] In step 11, as in Figure 2a As shown, the first magnetic field is used to magnetize the magnetizable material layer 10 along the first magnetization direction, and then a magnetic field in the same direction as the first magnetization direction is formed in the magnetizable material layer 10 .

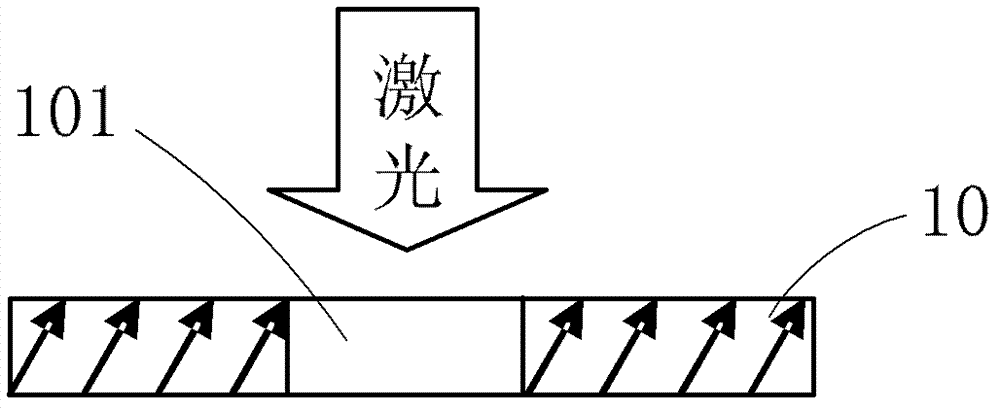

[0019] In step 12, as in Figure 2b As shown, a local region 101 of the magnetizable material layer 10 is heated and demagnetized by a laser beam. Specifically, the local region 101 of the magnetizable material layer 10 is heated to abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com