Magnetic printing equipment and magnetic printing method

A magnetic printing and equipment technology, which is applied in the direction of printing, printing, printing machines, etc. for the production of special types of printed matter, can solve the problem of single pattern effect and achieve the effect of variable pattern effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

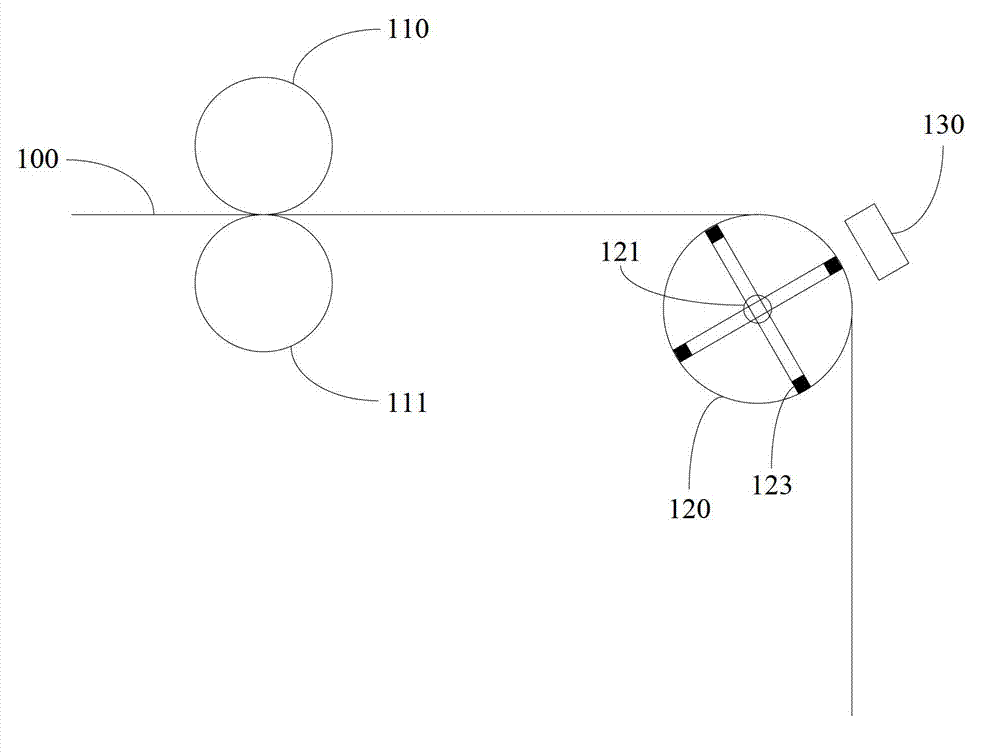

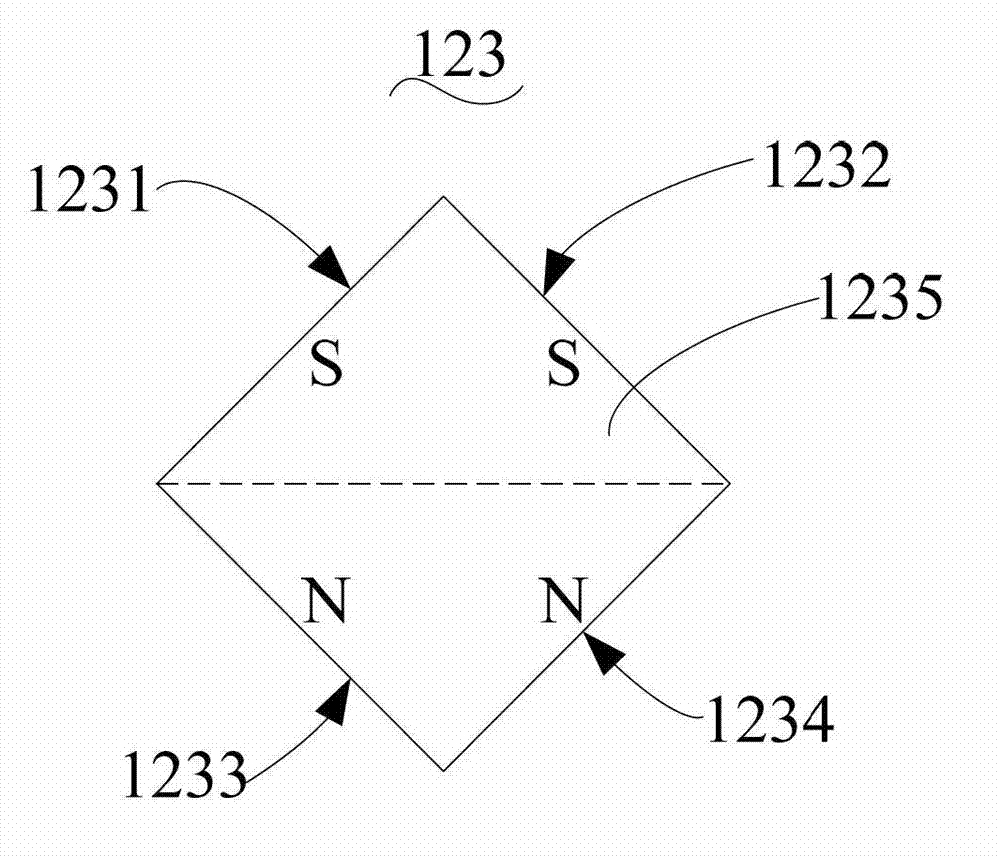

[0026] See figure 2 , figure 2 is a structural schematic diagram of the magnetic printing device of the first embodiment of the present invention. In this embodiment, the magnetic printing equipment is a roll-type continuous printing equipment, including printing devices 110 , 111 , a magnetic orientation device 123 , a curing device 130 and a conveying device 120 .

[0027] In this embodiment, the transfer device 120 transfers the printed matter substrate 100 through the printing devices 110 , 111 , the magnetic orientation device 123 and the curing device 130 . The printing devices 110 and 111 are respectively arranged in a cylindrical shape, and then can apply magnetic ink on the printed matter substrate 100 to be printed in a roll printing manner to form a magnetic ink layer (not shown). The printed matter substrate 100 can be flexible materials such as paper, cardboard, film and plastic that need to be magnetically printed. The magnetic ink layer contains magnetic pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com