Method for producing hyperfine texture decorative metal plate and hyperfine texture decorative metal plate

A metal plate, ultra-fine technology, applied in the preparation method of ultra-fine texture decorative metal plate and the field of metal plate, can solve the problems of variable pattern effect, high ornamental value, low cost of metal plate, etc., and achieve high ornamental value and low cost Effects of low cost and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] The present invention proposes a manufacturing method of using a soft mold to directly emboss a metal plate to obtain an ultra-fine texture decorative metal plate. This method can realize the manufacture of ultra-fine texture with a three-dimensional touch, and the raw materials used are non-toxic and pollution-free, solving the problem of many problems existing in the prior art. Specifically,

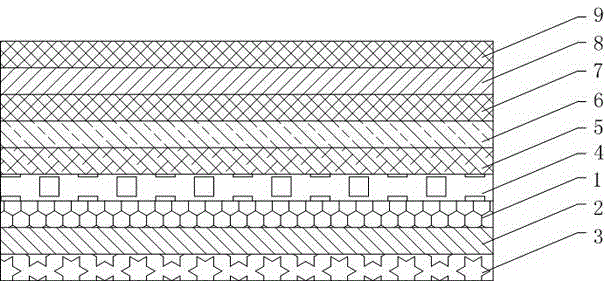

[0043] refer to figure 1 As shown, this embodiment is an ultra-fine texture decorative metal plate, including a substrate 1, a chemical treatment layer 2 and a back paint layer 3 are sequentially provided on the lower surface of the substrate 1, and the chemical treatment layer is sequentially provided on the upper surface of the substrate 1 from bottom to top. Layer 4, base coat 5, middle coat 6, printing pattern layer 7, embossing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com