Swing-up environment-friendly pit garbage compression station

A garbage compression station and garbage compression technology, which is applied in the directions of garbage conveying, garbage collection, loading/unloading, etc. It can solve the problems of low cleaning and transportation cost, low cost, low lifting weight, etc., and achieve good compression effect and high compression density. , The effect of large lifting weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

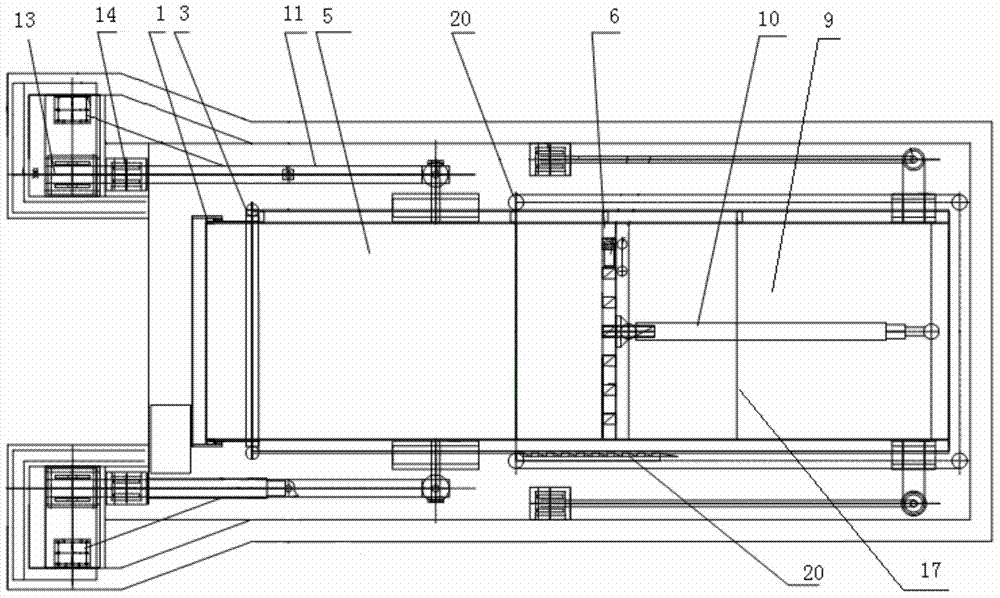

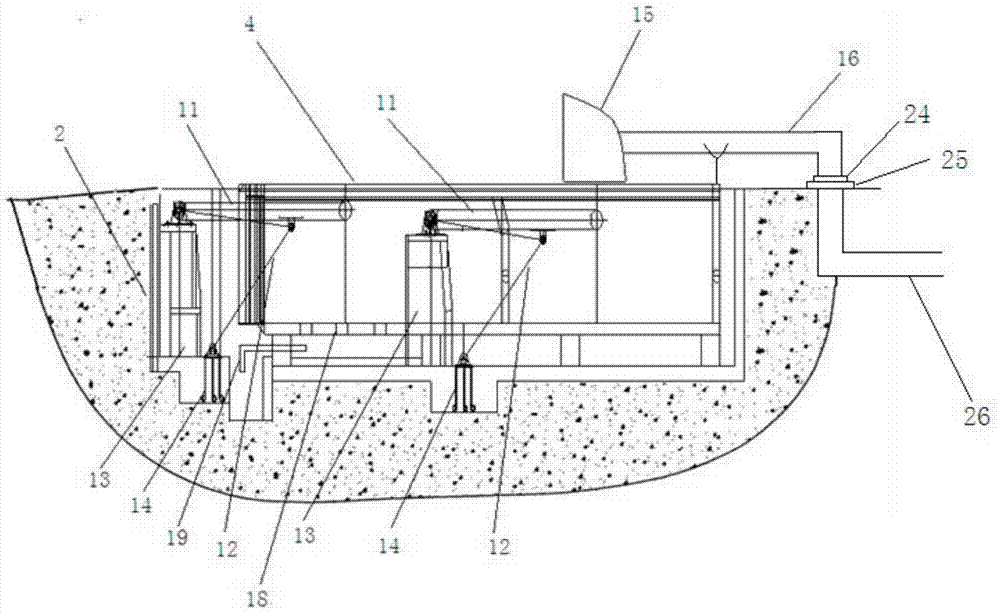

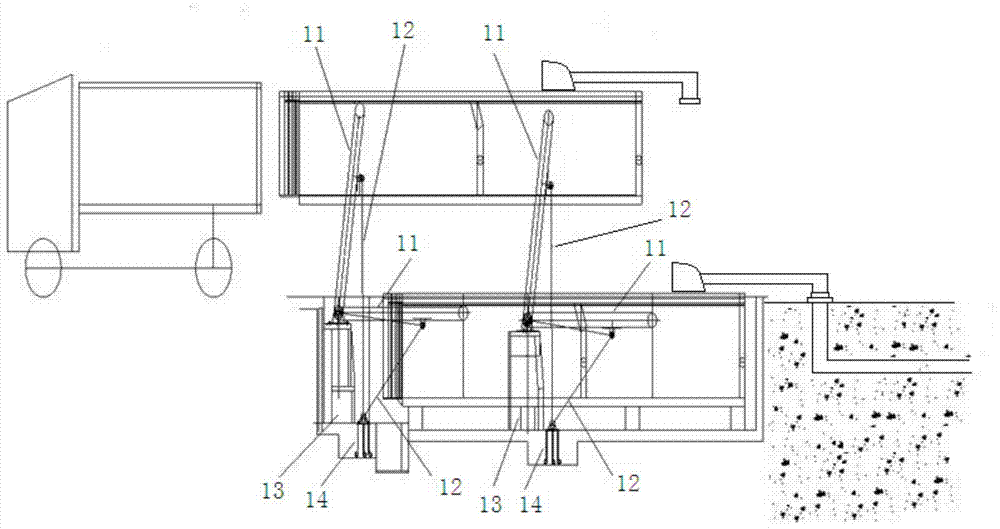

[0032] as attached figure 1 , attached figure 2 As shown, the swing-up type environment-friendly type pit lying garbage compression station of the present embodiment includes the pit 2 and the garbage compression box 4 arranged in the pit 2, the top surface of the garbage compression box 4 is flat with the ground, and the garbage compression The port of the box body 4 is provided with a front door 1 of the pre-press box, and a lifting cylinder 3 for the front door. A pushing plate 6 is arranged behind the front door 4 of the pre-press box, and a compression chamber is formed between the front door 4 and the pushing plate 6 of the pre-press box. 5. The box at the rear of the pusher plate 6 is the pusher cylinder chamber 9, and the middle part of the pusher cylinder chamber 9 is horizontally placed with a multi-stage push cylinder 10, and the pusher plate 6 is hinged on the multi-stage push cylinder 10, the garbage compression box 4 is installed on two groups of lifting mechan...

Embodiment 2

[0036] The structure of this embodiment is the same as that of Embodiment 1, except that the garbage compression box 4 of this embodiment is installed on three groups of lifting mechanisms. When the length of the garbage compression box 4 is longer or the weight of the lift is larger, three groups of lifting mechanisms can provide greater lift to lift the garbage compression box 4 from the pit 2, and the lifting mechanism can also be used according to The weight of the box that needs to be lifted is set in multiple groups, which is flexible and convenient, and the lifting is stable and the lifting weight is large.

Embodiment 3

[0038] as attached Figure 4 , attached Figure 5 , attached Figure 6 , attached Figure 7 As shown, the structure of this embodiment is the same as that of Embodiment 1, the difference is that the pusher plate of this embodiment includes an outer plate 8, an inner plate 7 and an oil cylinder support plate 23, and the outer plate 8, inner plate 7 and oil cylinder support plate 23 Distributed sequentially, a booster pin 22 is arranged between the outer plate 8 and the inner plate 7, and the booster pin 22 is fixed on the inner plate 7, and round holes are distributed on the outer plate 8, and the outer plate 8 is distributed with The position of the round hole matches the position of the booster pin 22 on the inner plate 7, the inner plate 7 is connected to the big end of the multi-stage push cylinder 10, and the cylinder support plate 23 is set behind the inner plate 7 and fixed on the multi-stage On the push cylinder 10 , a booster cylinder 21 is arranged between the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com