Water resistor for load test in generator and generator load testing device

A load test and generator technology, applied in the field of water resistance, can solve the problems affecting the stability of the load cylinder load, water vaporization, load drift, etc., and achieve the effect of maintaining the load without sudden change and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

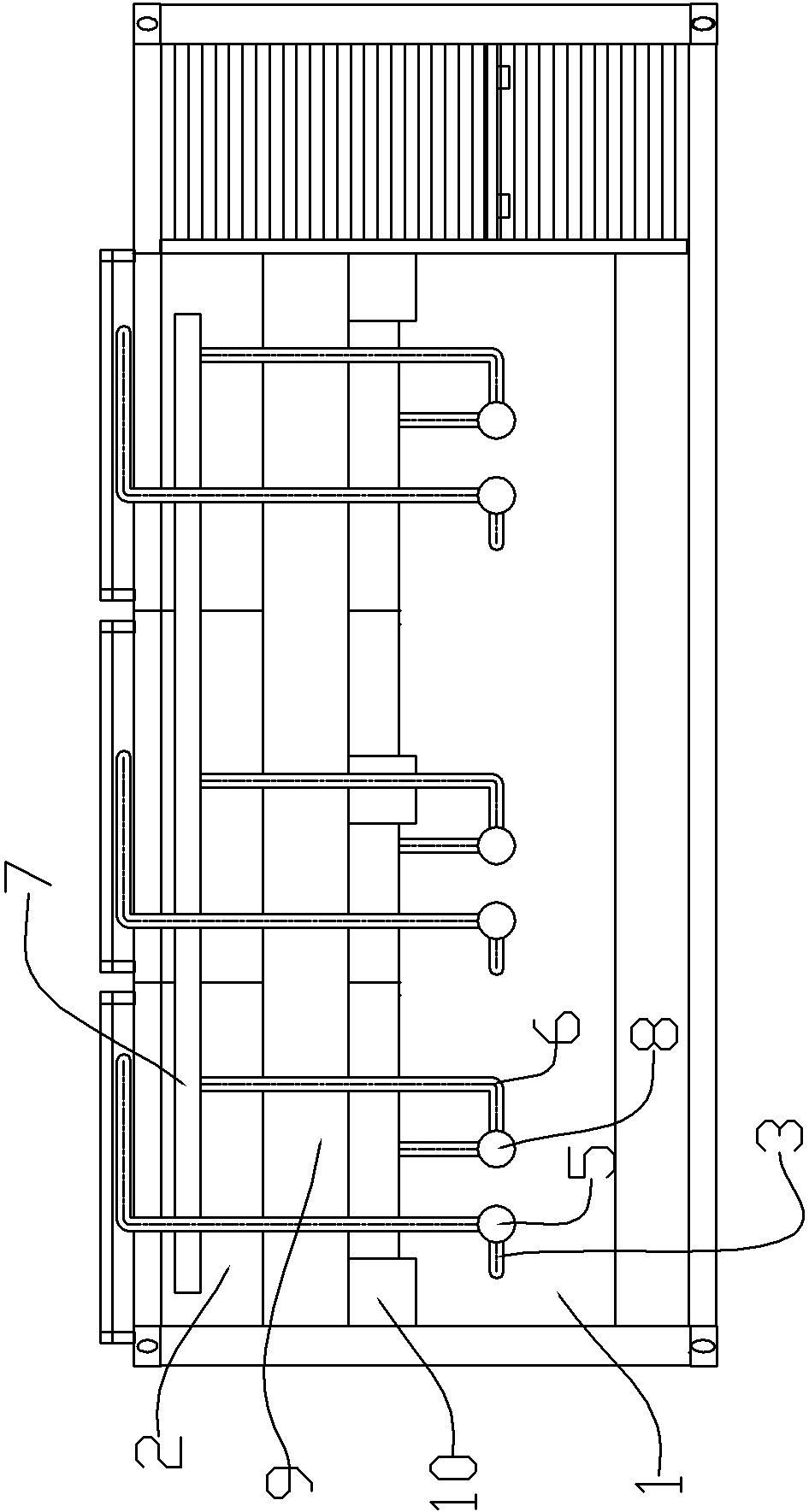

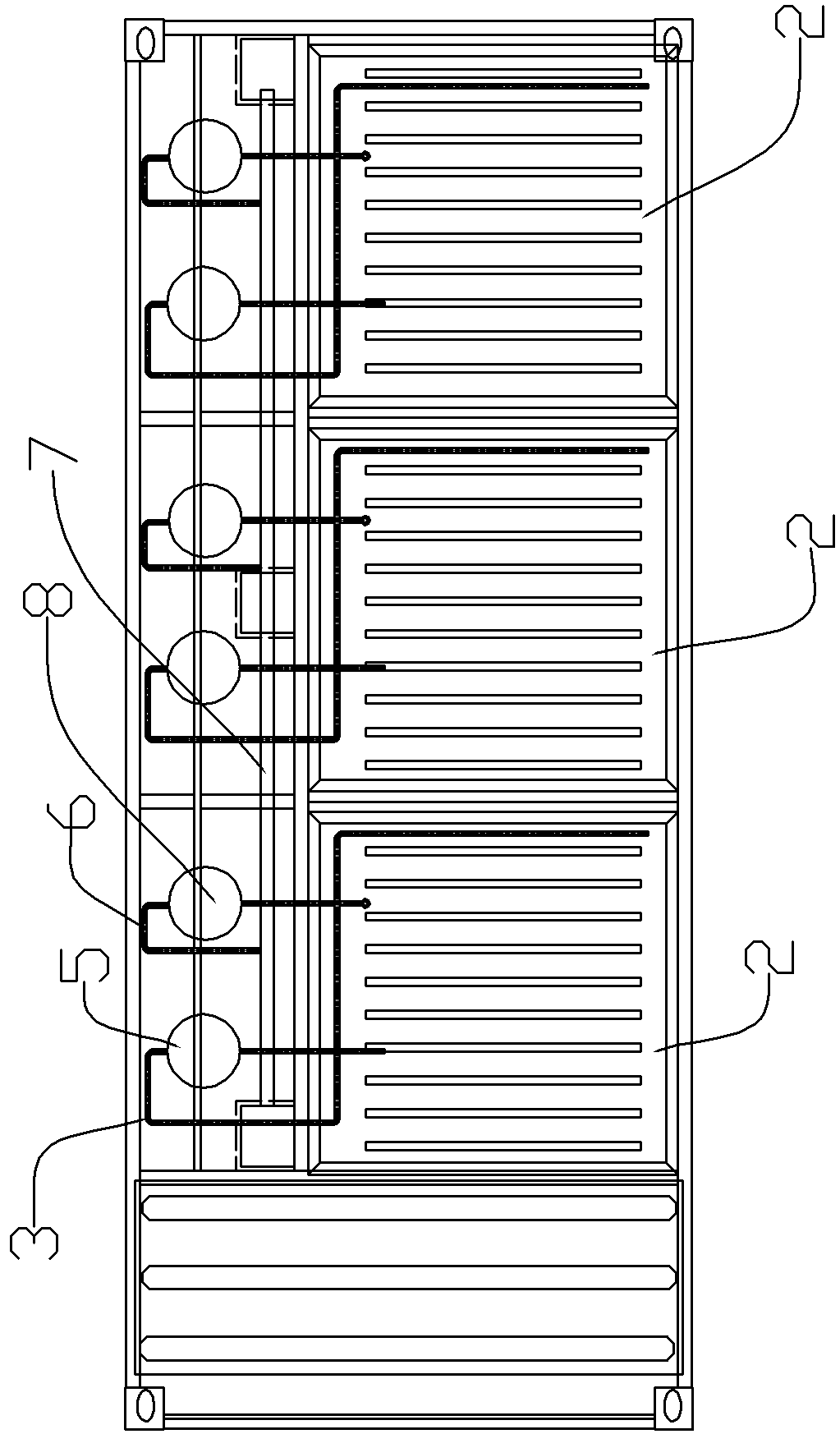

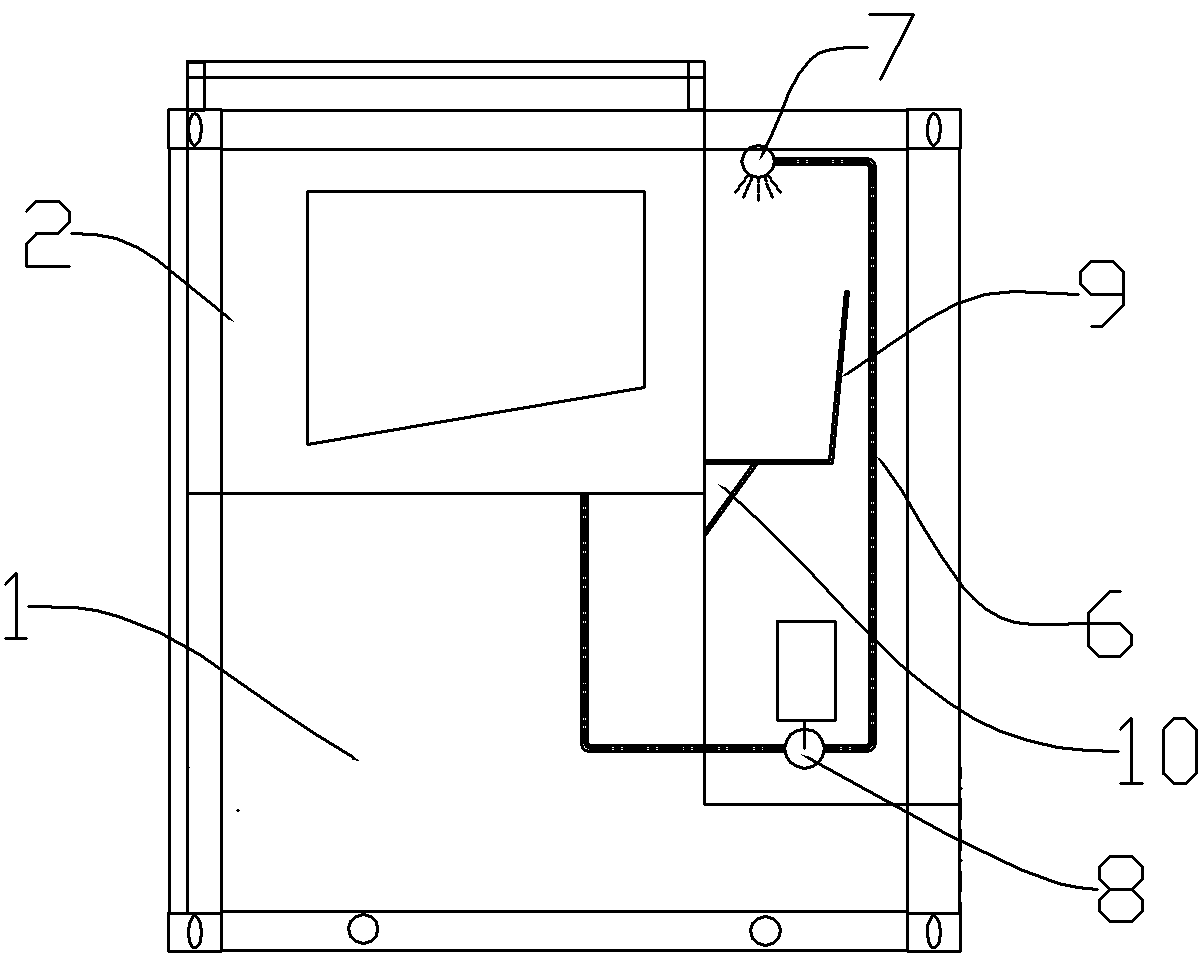

[0015] A water resistance for generator load tests such as figure 1 , figure 2 , image 3 , Figure 4 , including the water storage tank 1 at the bottom and the working water tank 2 with multiple electrode plates inserted above the water storage tank, the water inlet pipe 3 of the working water tank is connected to the water storage tank 1, and the water supply pump that pumps water from the water storage tank into the working water tank is installed on the water inlet pipe 5; the outlet pipe 6 of the working water tank is connected to the spray pipe 7, and the water pump 8 in the working water tank is installed on the outlet pipe to go out to the water discharge pump 8 in the spray pipe. The water receiving basin 9 of water content, the bottom of the water receiving basin communicates with the water storage tank 1 through the return water channel 10 again.

[0016] In order to control the change of the water level in the working water tank more gently in the test, the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com