Radial jitter detector for shaft

A detector and shaft radial technology, applied in the field of shaft workpiece radial runout detection equipment, can solve the problems of scrap, large error range, waste of resources, etc., and achieve the effect of wide measurement range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

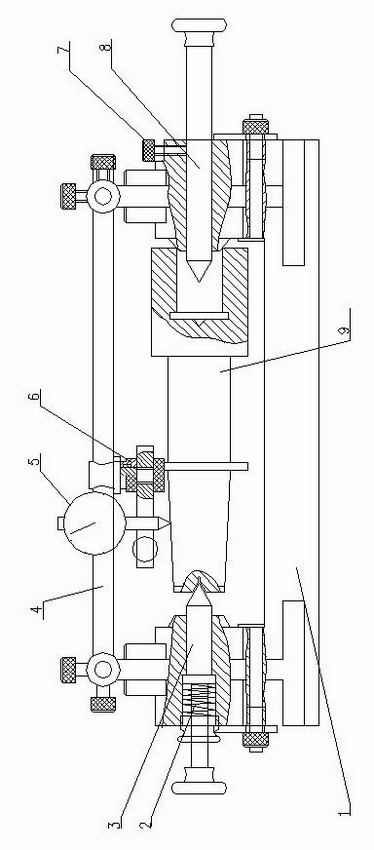

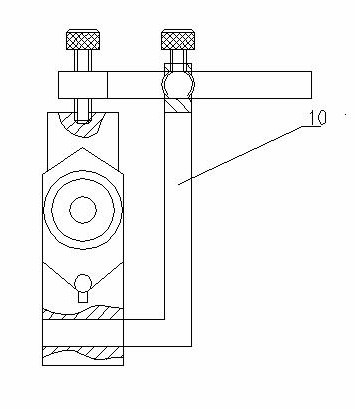

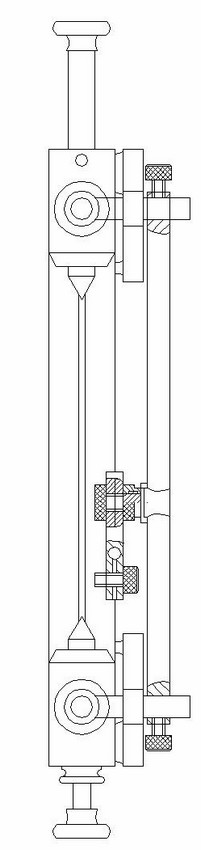

[0015] In order to further understand the shaft radial runout detector, combined with the accompanying drawings, the description is as follows:

[0016] Shaft radial runout detector, which mainly includes: sliding bearing guide rail, first adjustable center point, dial indicator, meter frame and second adjustable center point, the first adjustable center point and the second adjustable center point are respectively tangent to the guide rail , the first adjustable top has a built-in spring, the first adjustable top and the second adjustable top are fixed on the top fixing frame with fixing bolts, the top fixing frame is fixed on the sliding guide rail, and the beam is fixed on the sliding bearing guide rail through screw nuts , the table frame is suspended on the beam and slides horizontally on the beam, and the dial indicator is suspended on the beam and fixed by the table frame.

[0017] Working principle of the present invention:

[0018] The second adjustable top is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com