Method and device for quickly testing low temperature torque and similar viscosity of oil

A low-temperature, grease technology, applied in the field of testing, can solve the problems of high test cost, inability to detect the low-temperature performance of grease, long test period, etc., and achieve the effect of easy implementation, fast detection method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

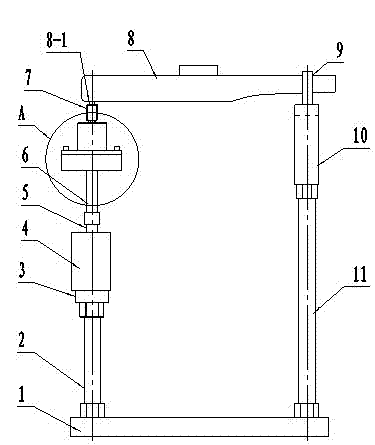

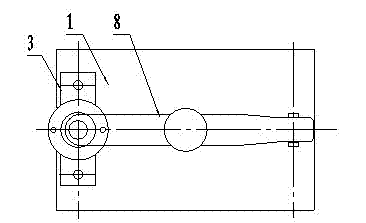

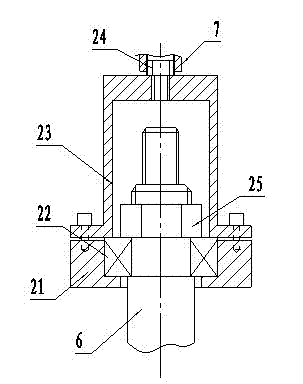

[0039] Embodiment 1, rapid test grease low temperature torque: see figure 1 , image 3, select a qualified D204 type single row radial ball bearing that has been cleaned and dried as the carrier bearing, fill the gap between the inner and outer rings of the carrier bearing with the grease to be tested, and then select the low temperature torque test component to place the carrier bearing 22 is put into the carrier bearing seat 21, the rotating shaft 6 is installed, and the gland 23 is fixed with the carrier bearing seat; the upper end of the gland is screwed into the connecting screw 24. After the preparations are done, put the assembled low-temperature torque test assembly into the low-temperature test chamber, set the temperature of the low-temperature chamber to -30±0.5°C, and keep the temperature for 2 hours after reaching the set temperature; take out the low-temperature torque test Assemblies, quickly connect the motor output shaft 5 with the rotating shaft 6, and then ...

Embodiment 2

[0040] Embodiment 2, quick test grease similar viscosity at low temperature: see Figure 4 , Image 6 , select low temperature similar viscosity test components, clean and dry the flange 31 with the groove 32, add the grease with similar viscosity to be tested in the groove, it is required to be filled and solid, no empty parts are allowed, and the end face is used The scraper is scraped flat; the flange is installed on the rotating shaft 6, and the fastening nut 25 is locked; the setting needle supporting bearing 36 and the setting needle supporting bearing seat 35 are installed on the upper end of the rotating shaft in sequence, and the setting needle supporting bearing is locked, and then The connection arm of the setting needle is fixed on the supporting bearing seat 35 by the connecting screw 24, the depth of the annular groove is 10 mm, the width is 10 mm, the diameter of the setting needle is 3 mm, and the depth of the setting needle probing into the annular groove is 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com