Structure for suppressing flow vibration of instrumentation guide tube

一种计量仪器、振动抑制的技术,应用在流动振动抑制构造领域,能够解决磨损等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

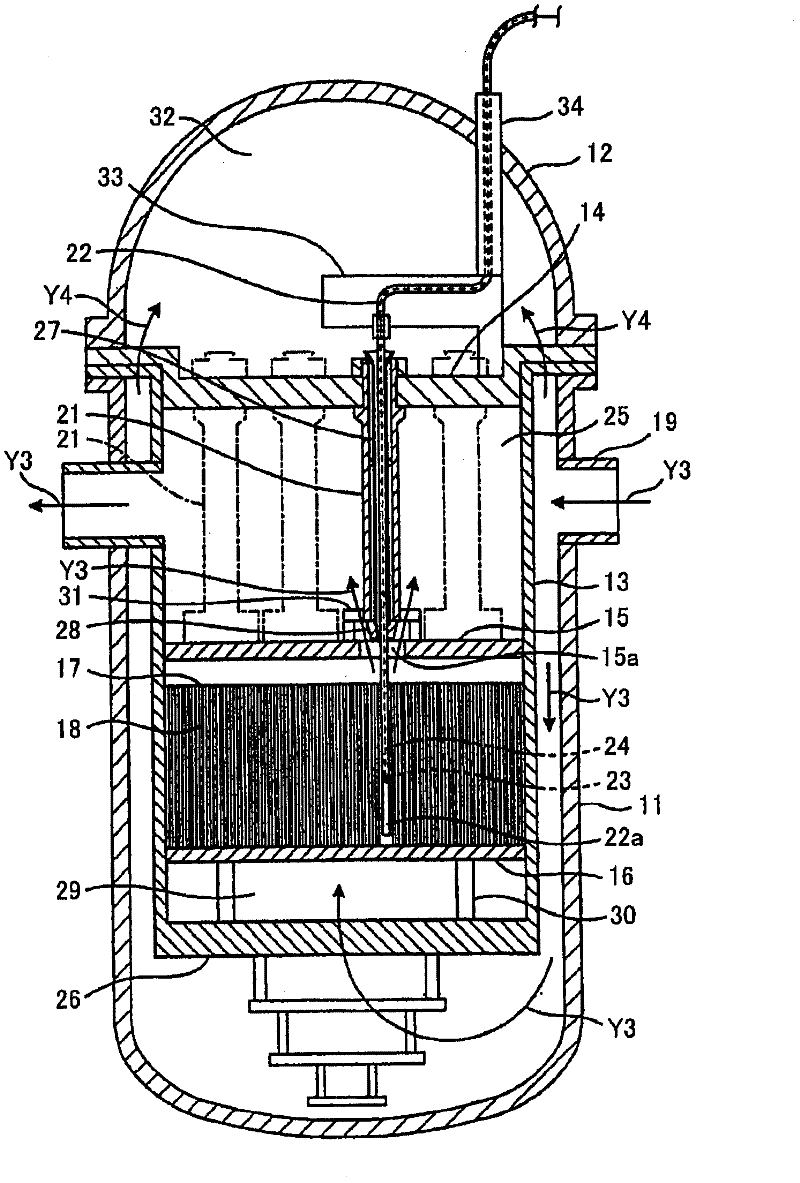

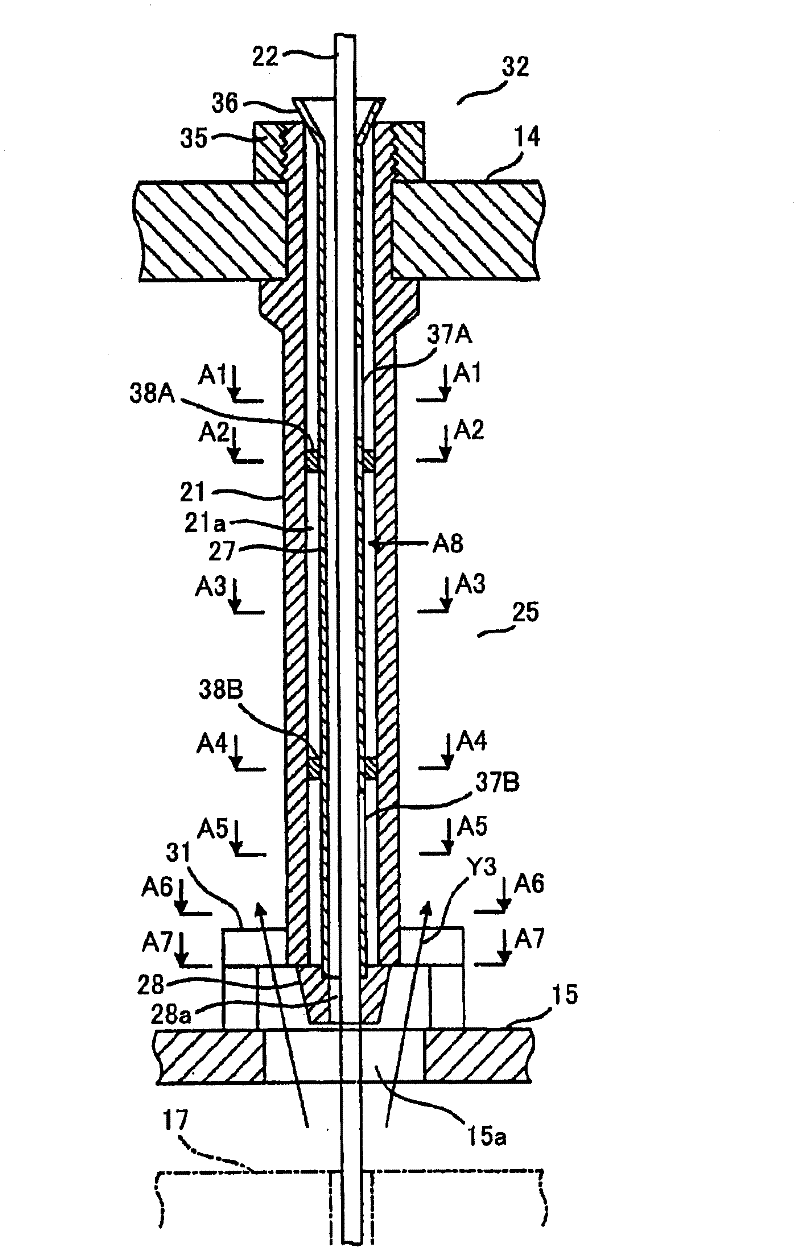

[0271]Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. The present invention is suitable for a PWR (pressurized water reactor) type reactor, but the application target of the present invention is not limited thereto, and the present invention can also be applied to a BWR (boiling water reactor) type reactor.

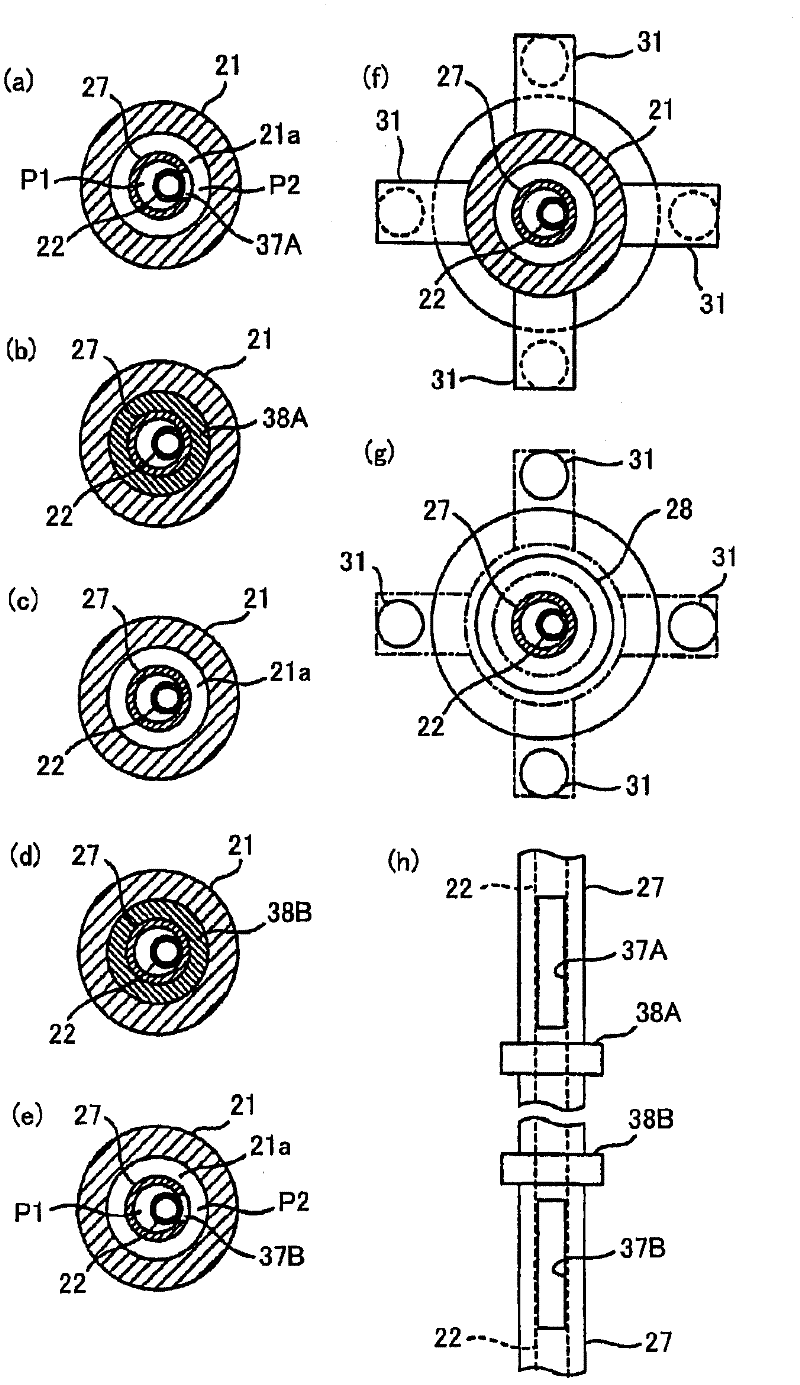

[0272] figure 1 It is a schematic cross-sectional view showing the internal structure of a PWR reactor vessel equipped with a flow vibration suppression structure of a gauge conduit according to a first embodiment of the present invention, figure 2 From figure 1 An enlarged cross-sectional view showing the flow vibration suppressing structure of the above-mentioned measuring instrument conduit extracted. in addition, image 3 (a) is figure 2 The A1-A1 line arrow observes the enlarged view of the section, image 3 (b) is figure 2 The A2-A2 line arrow observes the enlarged view of the section, image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com