Three-ring solid phase spot welding method

A solid phase point and collar technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of weak vertical interface, large welding tool load, low welding efficiency, etc., and can solve the problem of excessive upsetting force. Large, the effect of solving the weak connection problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

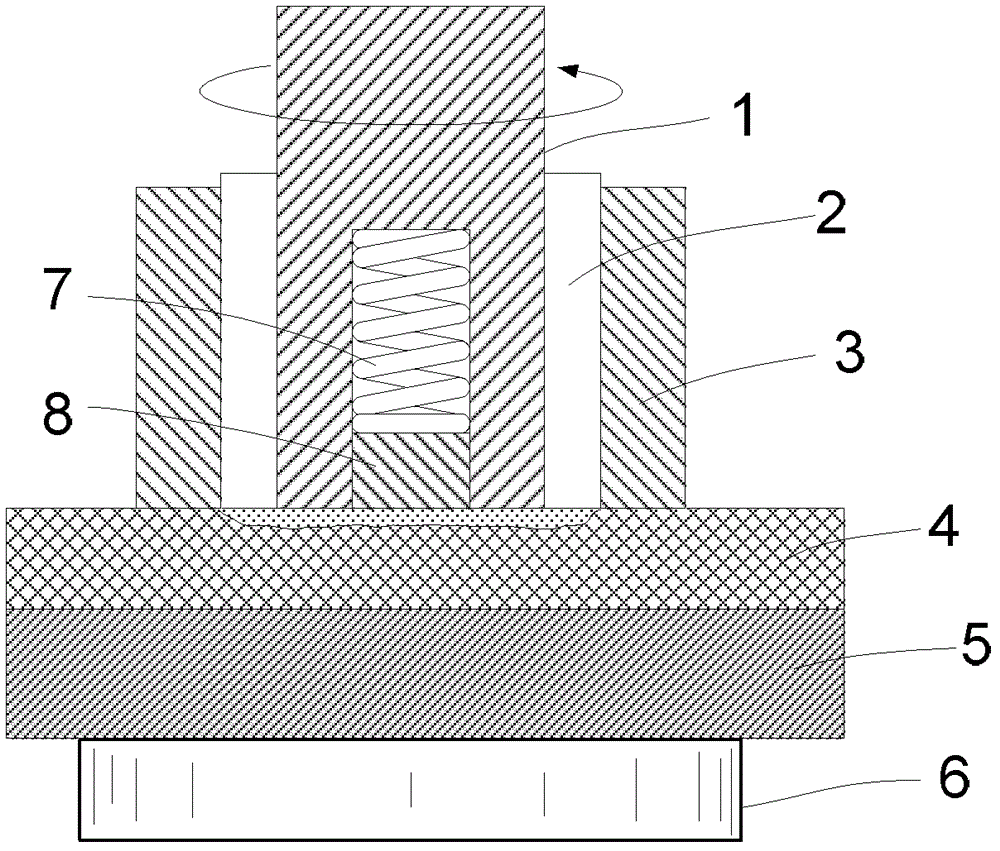

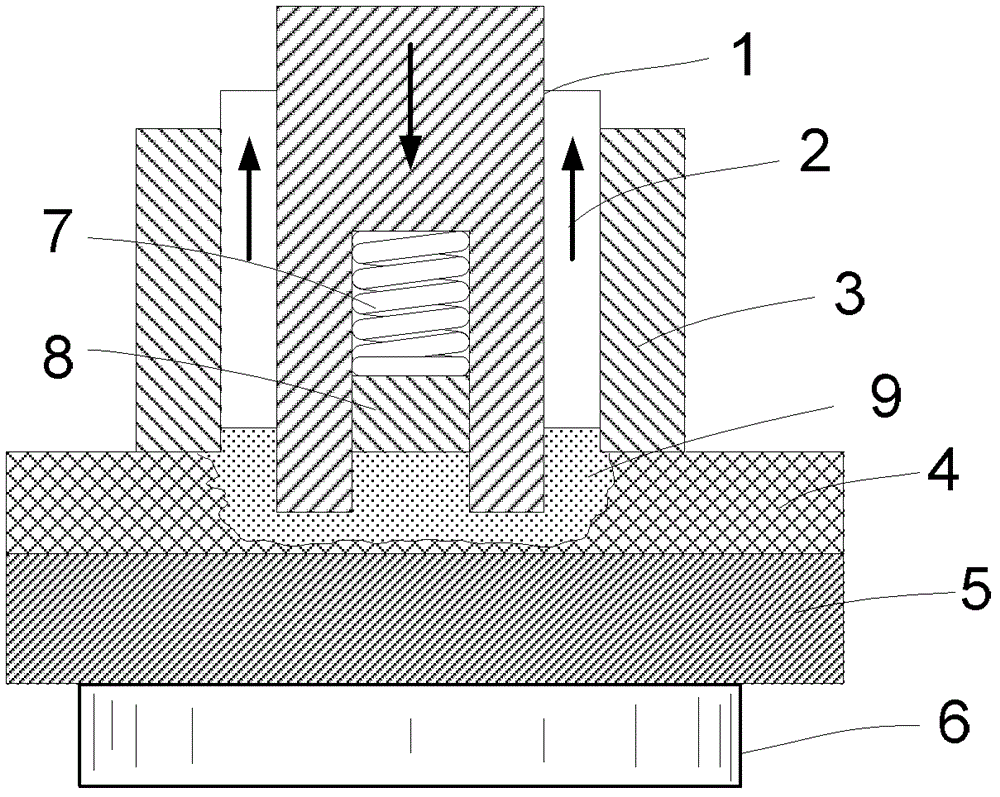

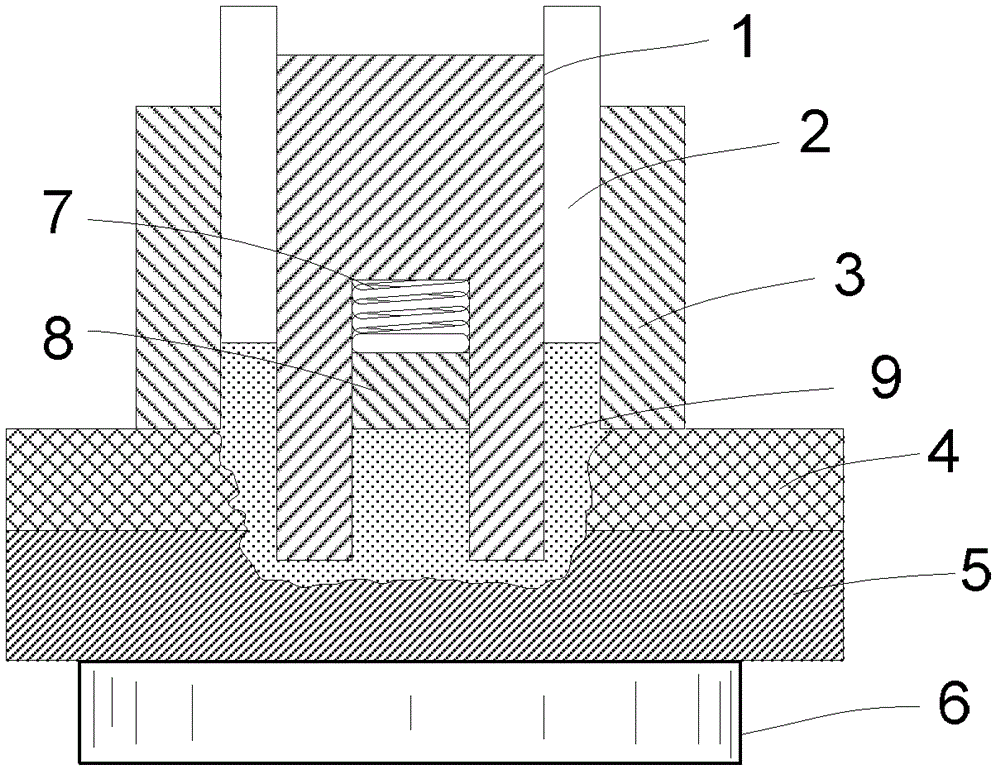

[0022] Such as Figure 1 to Figure 5 As shown, the three-ring solid-phase spot welding method provided by the preferred embodiment of the present invention comprises the following steps:

[0023] 1) Compression preheating stage: the outer ring 3 is pressed against the surface of the workpiece, which provides an axial displacement reference for the welding tool, and plays the role of constraining the material. The middle ring 2 and the inner ring 1 are pressed against the surface of the workpiece at the same speed When rotating, the frictional heat generated with the surface of the base metal will make the surrounding metal reach a plastic softening state.

[0024] 2) Extrusion and forging stage: while the inner collar 1 rotates at a high speed, it squeezes the base material downward, and the plastic metal 9 is discharged outward, and the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com