Filtration device and filtration method

The technology of a filtering device and a filtering method, which is applied to the electrolysis process, cells, electrolysis components, etc., can solve the problems of increased production cost and long time for changing the liquid medicine, so as to reduce the production cost, reduce the risk of dead ends of circulation, and reduce metal ions. The effect of the possibility of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

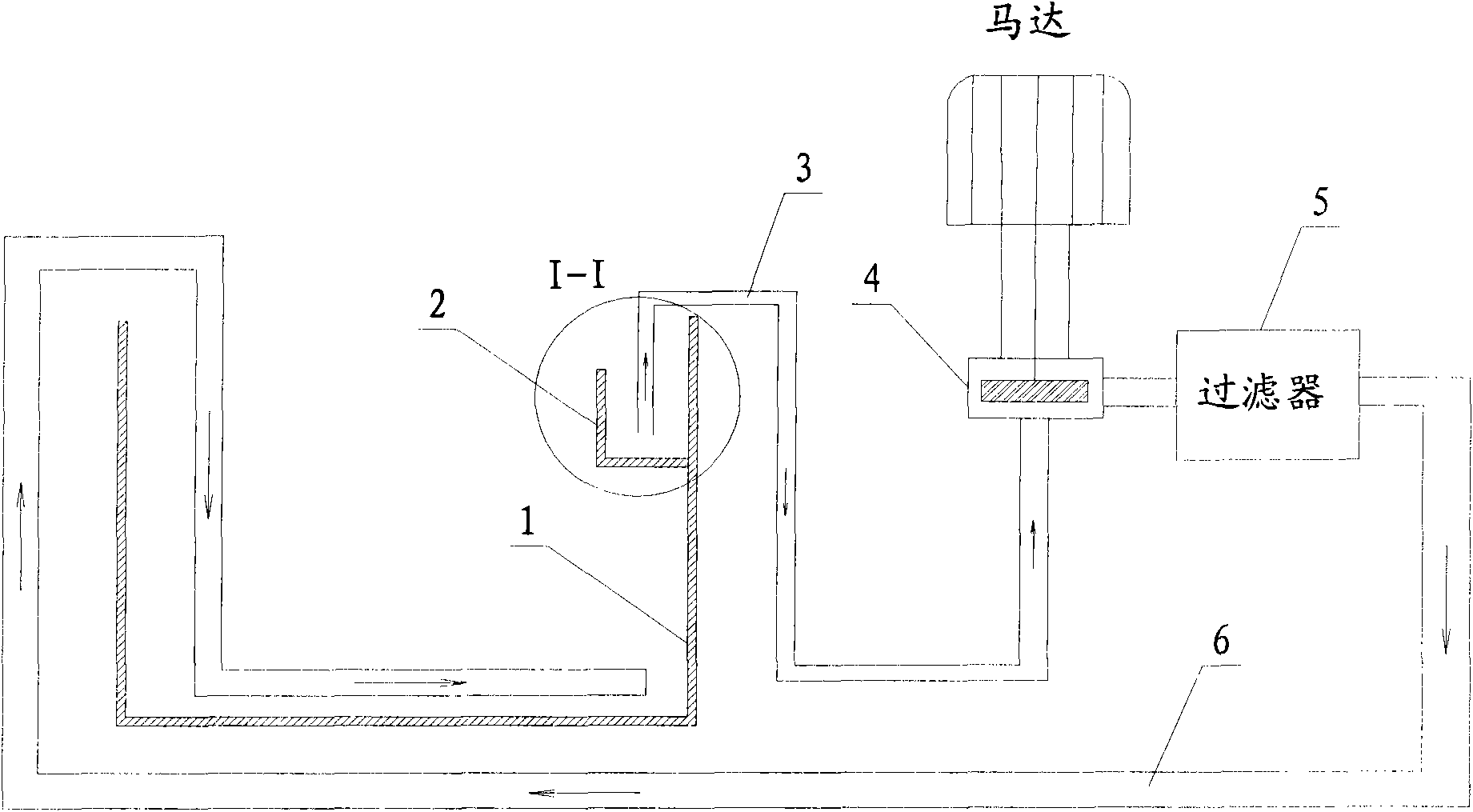

[0023] The invention provides a filtering device, comprising:

[0024] a main tank, which is used to hold the solution;

[0025] A liquid inlet pipe, which has a first inlet and a first outlet, the first inlet is arranged below the liquid level of the solution in the main tank, and the first outlet is connected to a filter;

[0026] a filter for filtering the solution;

[0027] A liquid outlet pipe, which has a second inlet and at least one second outlet, the second inlet is connected to the filter, and the at least one second outlet is located in the main tank and is inclined or vertically toward the main tank the bottom of the tank;

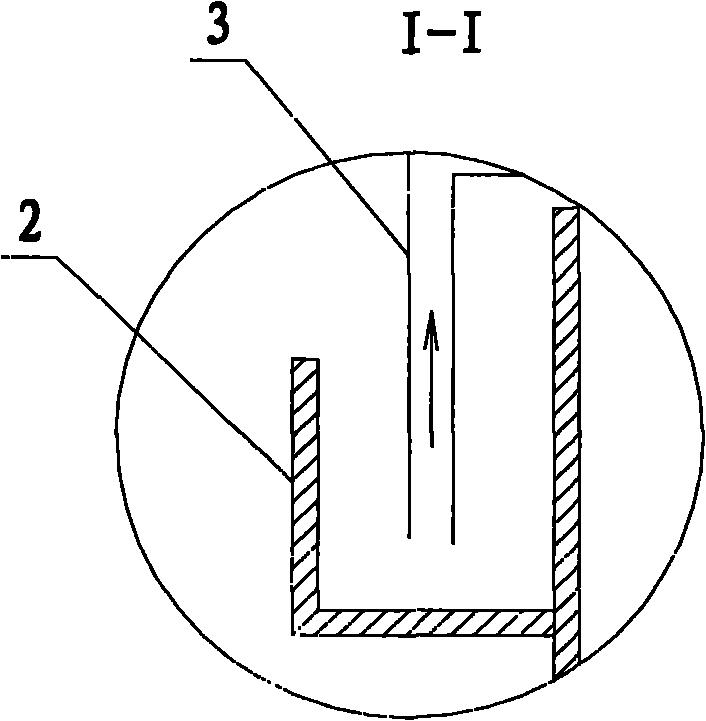

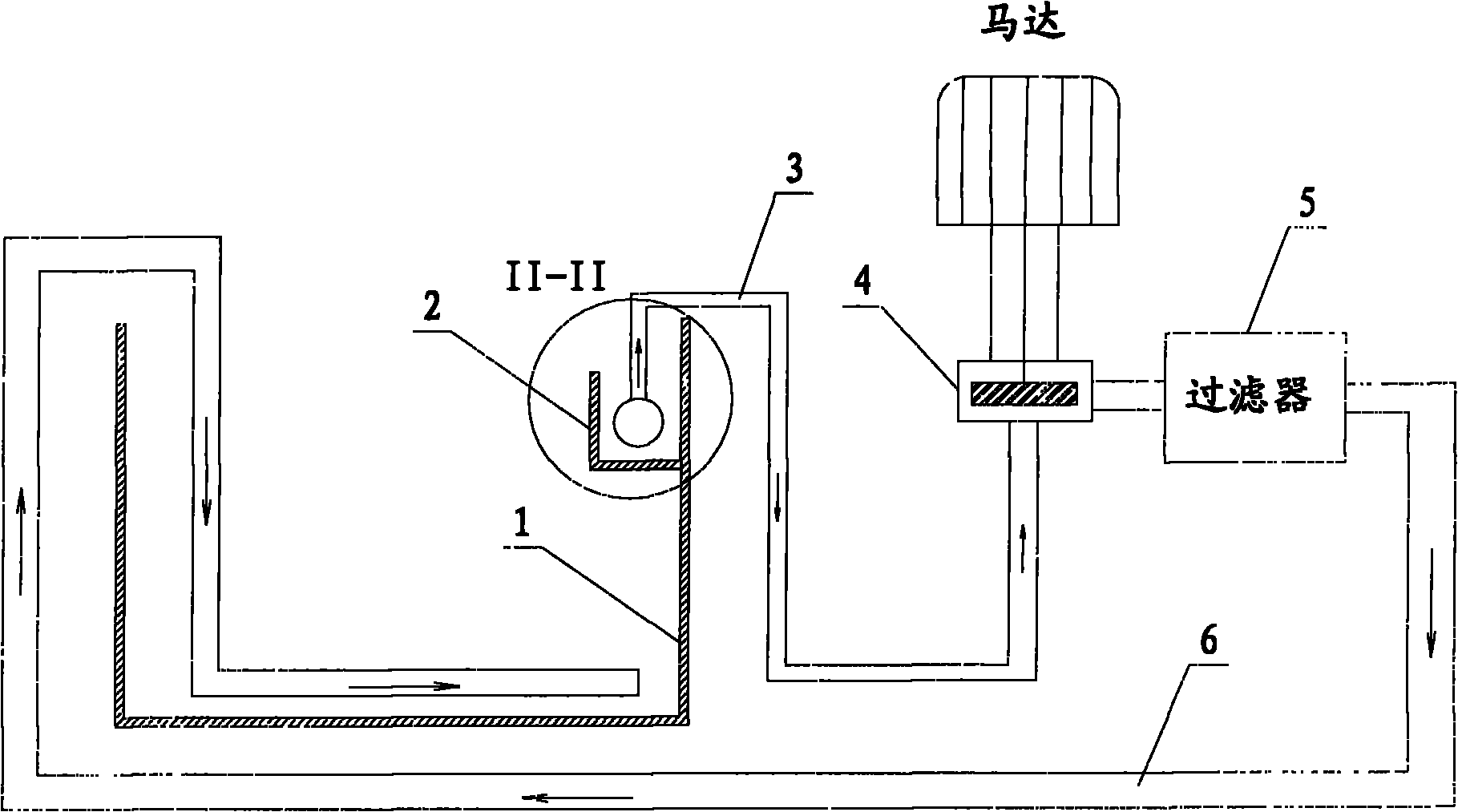

[0028] It is characterized in that at least the first inlet among the first inlet, the first outlet, the second inlet and the second outlet is connected with a conduit, the surface of the conduit is provided with a plurality of through holes, and the plurality of The vias face at least two different directions.

[0029] In a preferred embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com