A kind of anti-aging TPE particle and preparation method thereof

An aging-resistant and granular technology, applied in the field of aging-resistant TPE particles and their preparation, can solve the problems of short service life, weak aging resistance, and oil leakage, so as to reduce the possibility of rubber oil precipitation and degradation. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 6

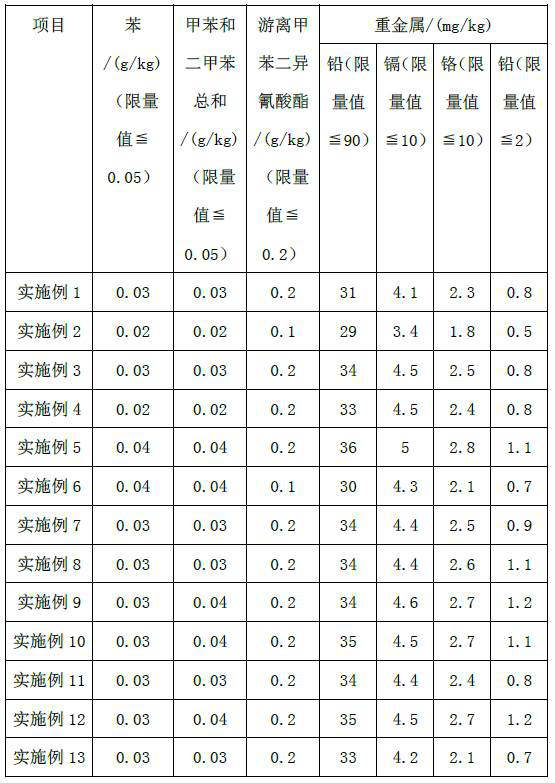

[0056] Example 1-Example 6 all adopt the same preparation method to prepare TPE particles, the only difference is that the dosage of each raw material component is different, see Table 2 for details:

[0057] The dosage of each raw material component in the embodiment 1-embodiment 6 of table 2

[0058]

[0059]

[0060] Among the embodiment 1-embodiment 6, the base material is all mixed by the SBS and SEBS that the weight ratio is 2:1, and the toner is all mixed by the phthalocyanine green powder and other auxiliary toners that the weight ratio is 3:1 Other auxiliary toners can be selected according to actual needs to color TPE particles, such as yellow masterbatches and black masterbatches sold by Dongguan Jinsuyan Plastic Technology Co., Ltd. The order number of the talc powder in embodiment 1-embodiment 2, the heavy calcium powder in embodiment 3-embodiment 4 and the wollastonite powder in embodiment 5-embodiment 6 is 800 orders.

[0061] In Example 1-Example 6, the ...

Embodiment 7

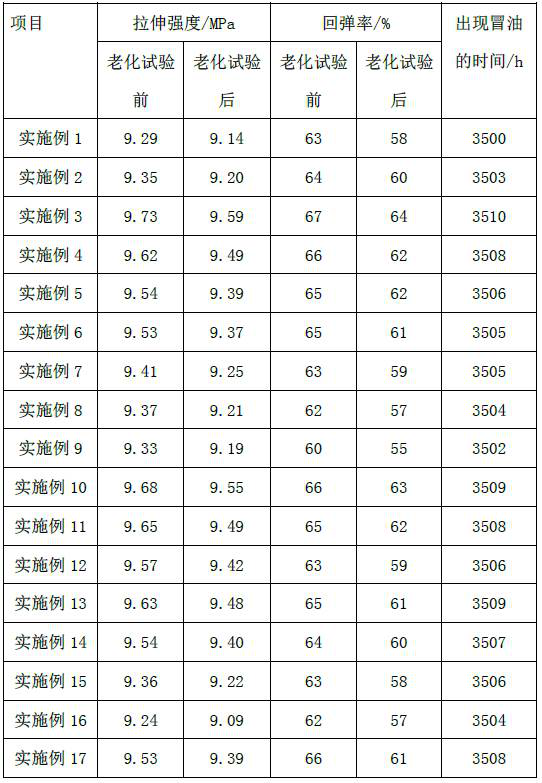

[0067] The difference between this example and Example 3 is that the oil-locking additive is made by mixing and granulating 11.5g of 2-mercaptobenzimidazole and 85g of polypropylene.

Embodiment 8

[0069] The difference between this example and Example 3 is that the oil-locking additive is made by mixing and granulating 8g of 2-mercaptobenzimidazole and 87g of polypropylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com