An antimony sulfide solar cell using a CuI/PbPc thin film as a hole transport layer and a preparation method thereof

A technology for solar cells and hole transport layers, which is used in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

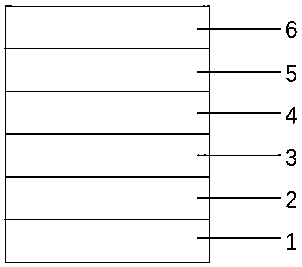

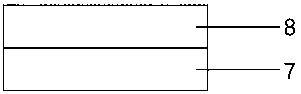

Embodiment 1

[0021] First, take a piece of ITO conductive glass, and use acetone, methanol, and isopropanol to perform ultrasonic cleaning for 10 minutes respectively, blow it dry with nitrogen, and then irradiate it with ultraviolet light for 10 minutes to dry it; use chemical vapor deposition to deposit black phosphorene film on a transparent conductive substrate; then, on the transparent conductive substrate, a thin film of antimony sulfide is deposited by vacuum evaporation and annealed at a high temperature, and then on the thin film of antimony sulfide, a film containing tetramethyl-p-phenylenediamine and tetramethyl-p-phenylenediamine is deposited by vacuum evaporation. The organic semiconductor thin film formed by cyanoquinone dimethane compound; then the PbPc thin film was deposited on the organic semiconductor thin film by vacuum evaporation method; the CuI thin film was deposited on the PbPc thin film by dipping method; finally, the vacuum evaporation method was used to deposit th...

Embodiment 2

[0023] First, take a piece of FTO conductive glass, and use acetone, methanol, and isopropanol to perform ultrasonic cleaning for 8 minutes respectively, blow it dry with nitrogen, and then irradiate it with ultraviolet light for 12 minutes to dry it; use chemical vapor deposition to deposit black phosphorene film on a transparent conductive substrate; then deposit antimony sulfide film on the transparent conductive substrate by solvothermal method and anneal at high temperature, and then use spin coating method to deposit tetramethyl-p-phenylenediamine and tetracyano on the antimony sulfide film. The organic semiconductor film formed by the quinone dimethane compound; then the PbPc film was deposited on the organic semiconductor film by vacuum evaporation; the CuI film was deposited on the PbPc film by the solution ultrasonic method; finally, the CuI film was deposited on the CuI film by screen printing Depositing the metal electrodes means making the solar cell.

Embodiment 3

[0025] First, take a piece of AZO conductive glass, and use acetone, methanol, and isopropanol to perform ultrasonic cleaning for 6 minutes respectively, blow dry with nitrogen, and then irradiate with ultraviolet light for 8 minutes to make it dry; use mechanical stripping method to deposit black phosphorene film on on a transparent conductive substrate; then deposit an antimony sulfide film on the transparent conductive substrate by chemical bath deposition and anneal at a high temperature, and then deposit tetramethyl-p-phenylenediamine and tetracyanide on the antimony sulfide film by vacuum evaporation The organic semiconductor thin film formed by the quinone dimethane complex; then the PbPc thin film was deposited on the organic semiconductor thin film by vacuum evaporation; the CuI thin film was deposited on the PbPc thin film by solution ultrasonic method; finally, the CuI thin film was deposited on the CuI thin film by screen printing method. Metal electrodes are deposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com