Pressure reducing valve structure and method for adjusting gas pressure

A gas pressure and pressure reducing valve technology, applied in safety valves, balance valves, valve devices, etc., can solve the problems of complex pressure regulation process, long time, and inability to stabilize the outlet pressure within a certain range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

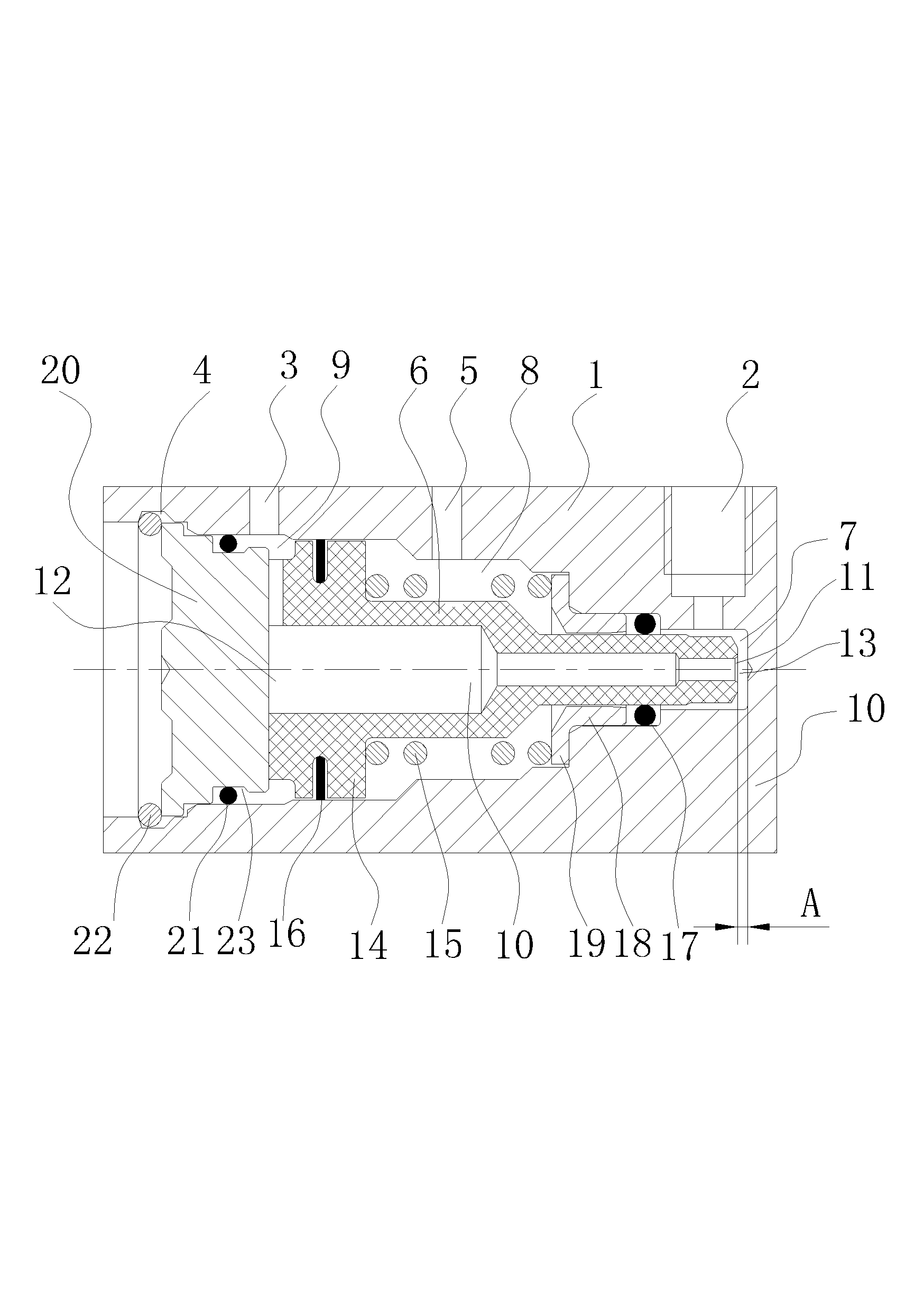

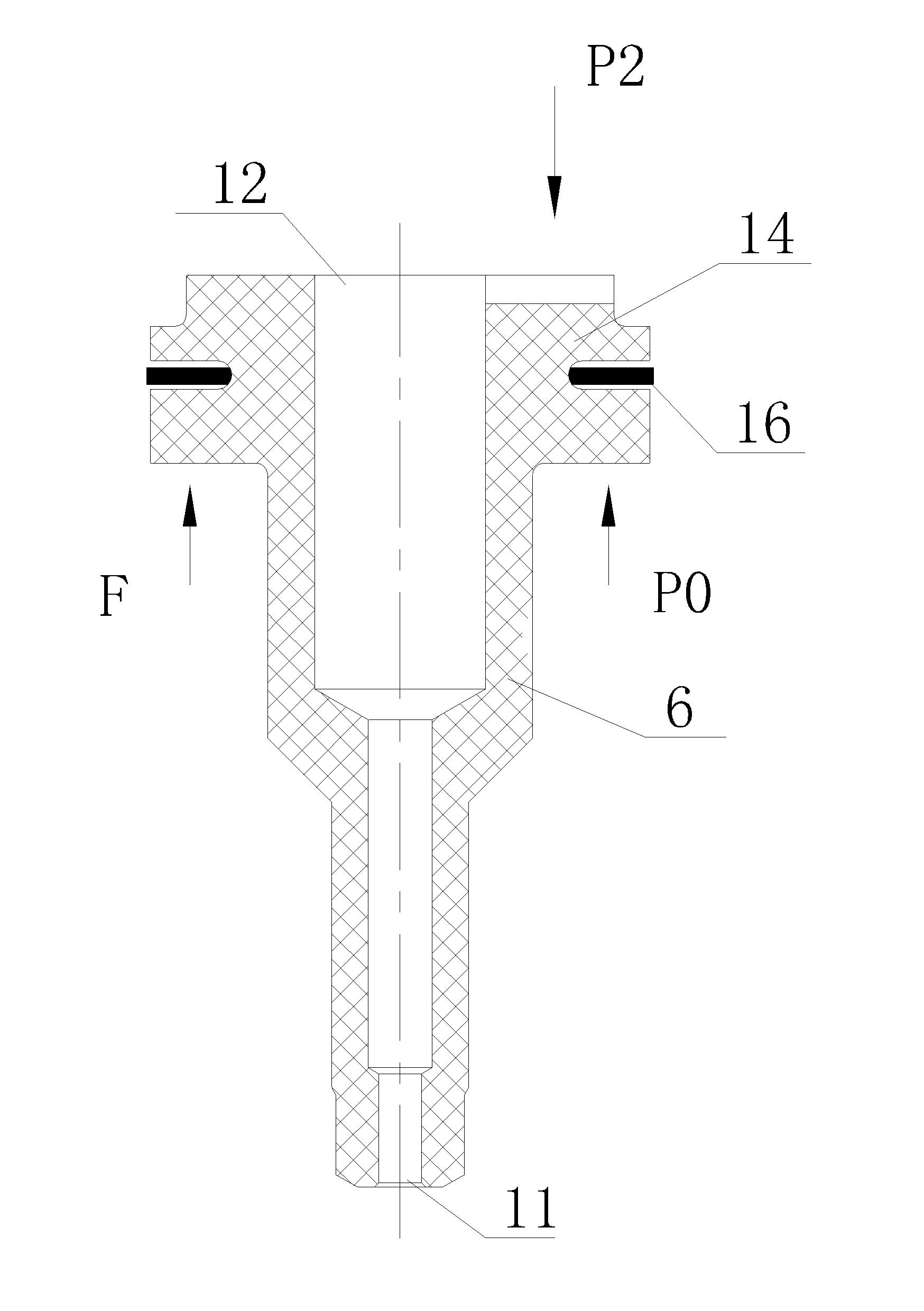

[0015] A pressure reducing valve structure for regulating gas pressure, see figure 1 : It includes the pressure input port 2, the pressure output port 3 and the end sealing plug of the valve core body 1, the end sealing plug is located on the side of the pressure output port 3 of the valve core body 1, and the middle part of the valve core body 1 has an atmospheric communication port 5. There is a pressure balance shaft 6 inside the valve core body 1, and the inner wall of the valve core body 1 cooperates with the outer edge surface of the pressure balance shaft 6 and the inner wall of the end sealing plug respectively to form a pressure input chamber 7, an atmosphere communication chamber 8, and a pressure The output cavity 9, the three cavities are sealed and isolated by seals, the pressure input port 2, the atmospheric communication port 5, and the pressure output port 3 are respectively connected to the pressure input cavity 7, the atmospheric communication cavity 8, the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com