Fuel cell system

A technology of fuel cell system and fuel stack, which is applied in the direction of fuel cell additives, etc., can solve the problems of reduced humidification effect, influence of membrane performance, single manufacturer, etc., and achieves the effects of cost reduction, guaranteed power generation efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

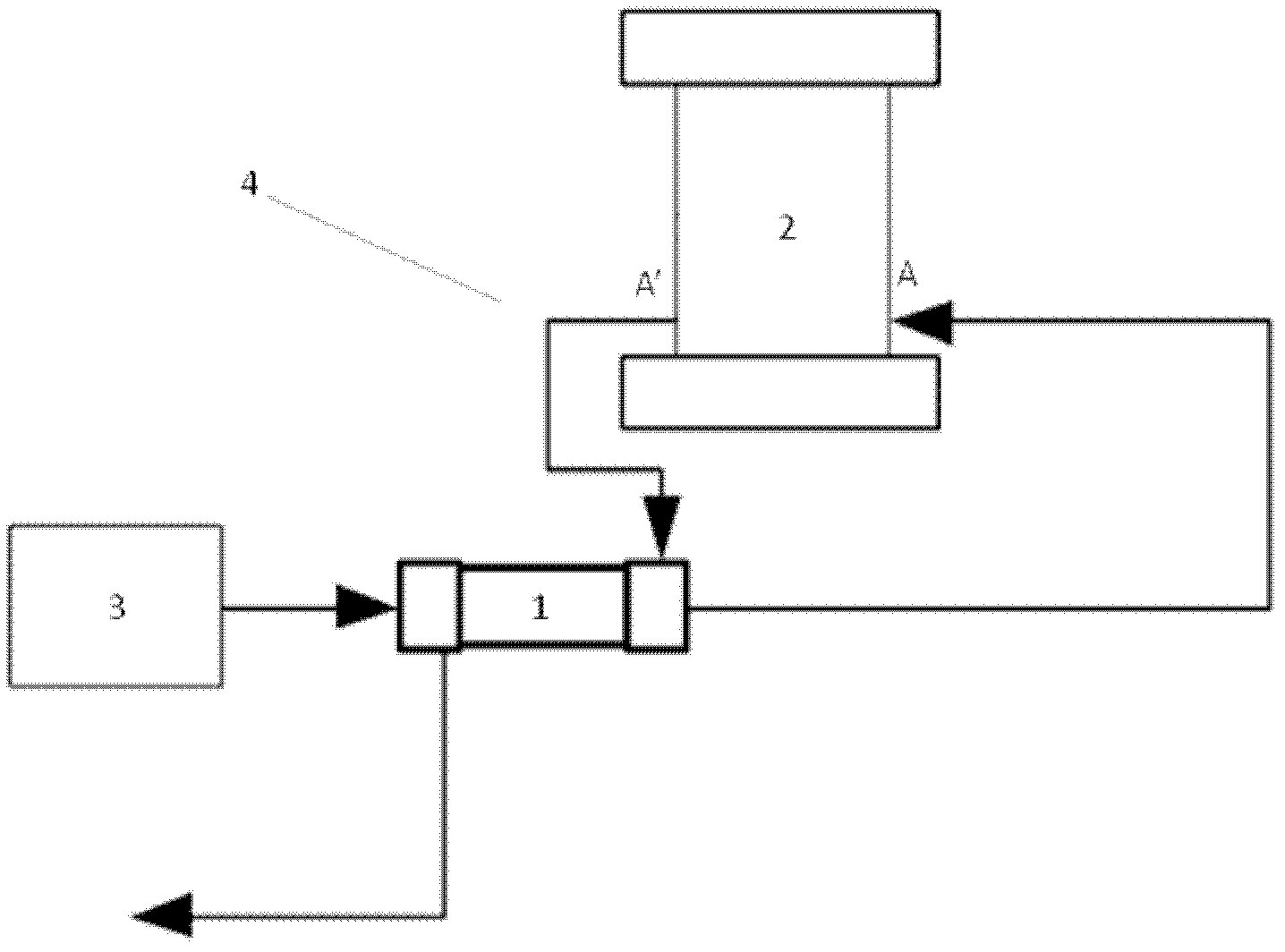

Method used

Image

Examples

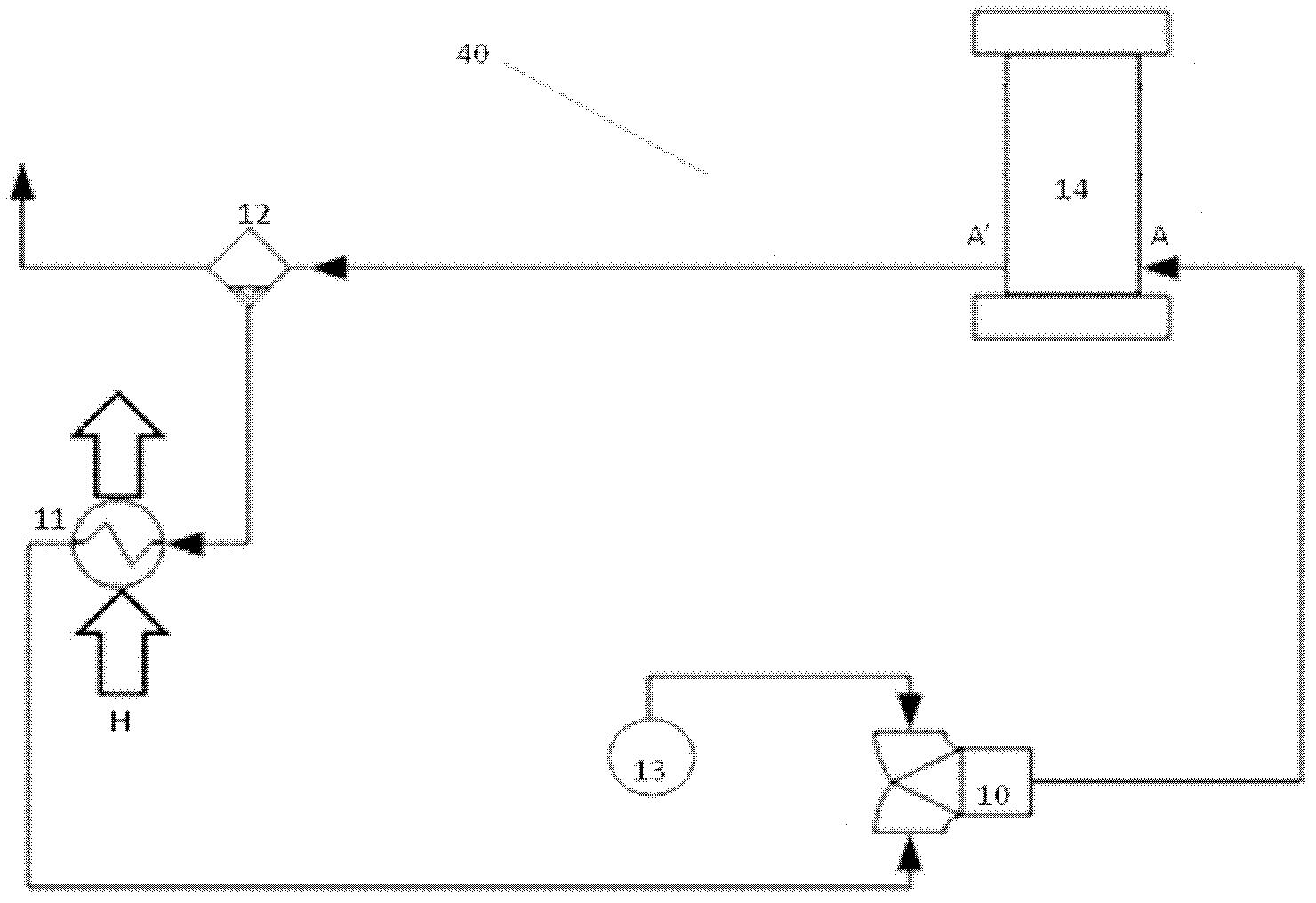

Embodiment 1

[0034] A fuel cell system is provided which includes a fuel stack ( -1310, purchased from Canada Ballard Power Systems Inc.), the fan that sends into the outside air, the first moisture separator (AF4000 type automatic drainer that is connected to each other with the cathode outlet of the fuel stack, purchased from Albes Pneumatic Co., Ltd., Wenzhou City, Zhejiang Province), the first shell-and-tube heat exchanger (8H25 type, purchased from Shanghai Ou Deke Fluid Treatment Equipment Co., Ltd.) connected to the first water-gas separator and the three-way pipe joint as a mixing device ( 30mm green tee joint, purchased from Fangdun Instrument Valve Co., Ltd., Wenzhou City, Zhejiang Province), the layout of these parts can refer to the present invention figure 2 shown; wherein, the cooling mode of the fuel cell system is to deliver water to the cooling channel in the fuel cell stack, the output power of the fuel cell system is 3.7kW, and the fuel processing subsystem (which incl...

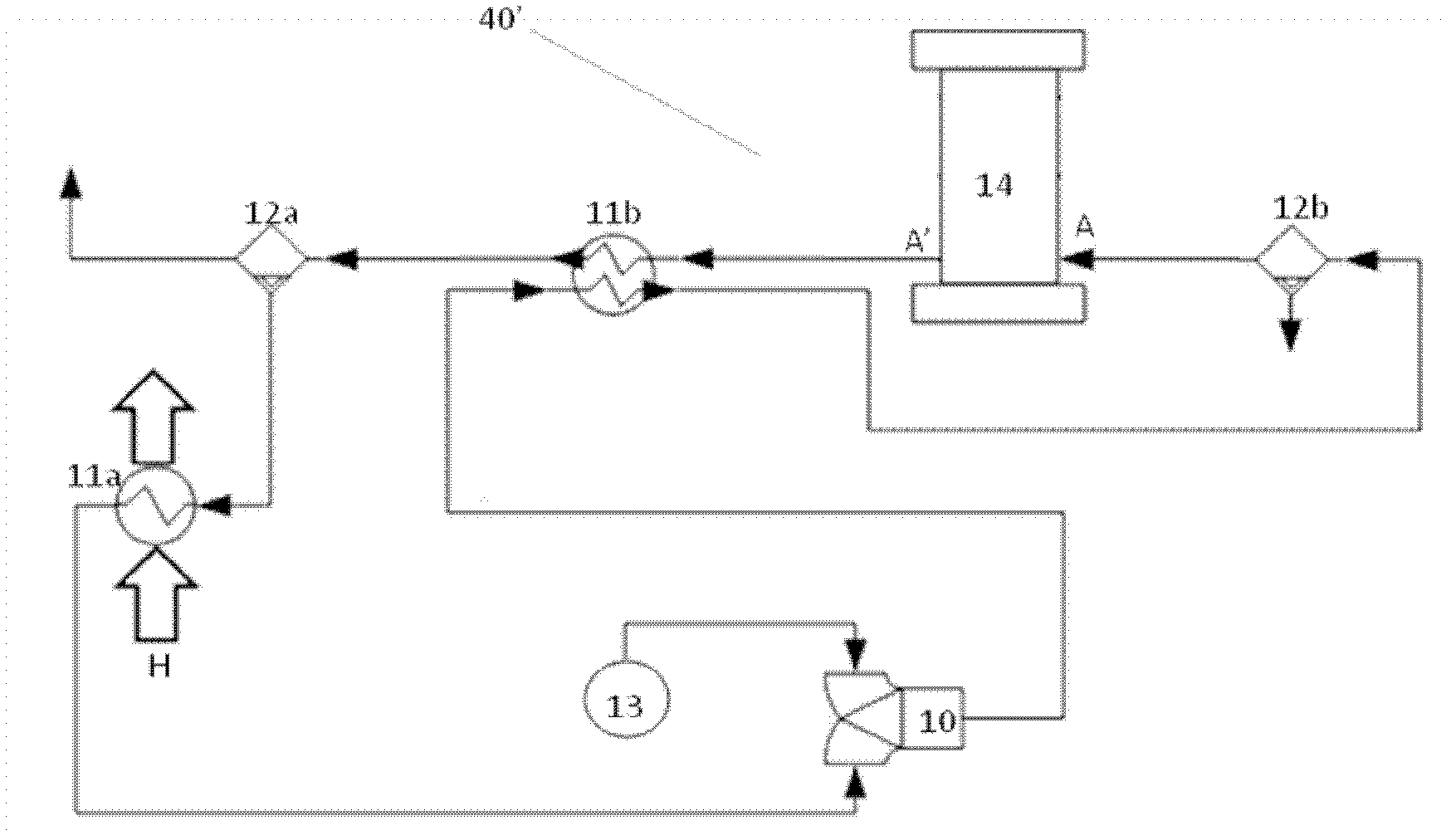

Embodiment 2

[0040] A fuel cell system is provided which includes a fuel stack ( -1310, purchased from Canada Ballard Power Systems Inc.), the fan that sends into the outside air, the first moisture separator (AF4000 type automatic drainer that is connected to each other with the cathode outlet of the fuel stack, purchased from Albes Pneumatic Co., Ltd., Wenzhou City, Zhejiang Province), the first plate heat exchanger (Alfa Nova 27-20 type, purchased from Sweden Alfa Laval company) connected with the first water-gas separator, the three-way pipe joint (30mm Green Three Common connector, purchased from Fangdun Instrument Valve Co., Ltd., Wenzhou City, Zhejiang Province), the second water-gas separator (AF4000 automatic drain, purchased from Albeis Pneumatic Co., Ltd., Wenzhou City, Zhejiang Province) and the second plate heat exchanger (Alfa Nova 27-20 type, purchased from Sweden Alfa Laval Company) arranged between the cathode outlet of the fuel stack and the first water-gas separator, T...

Embodiment 3

[0046] A fuel cell system is provided, which includes a fuel stack (9SSL stack product, purchased from Canada Ballard Power Systems Inc.), a fan that sends in external air, and the first moisture separator connected to the cathode outlet of the fuel stack (JAD402-S type, purchased from Jingwei Machinery Factory, Fenghua City, Zhejiang Province), the first plate heat exchanger connected to the first water-gas separator (B5-SN-S type, purchased from Sweden SWEP company, Lands crona City), a tee pipe joint as a mixing device (20mm quick-plug tee joint, purchased from Albes Pneumatic Co., Ltd., Wenzhou City, Zhejiang Province), and a second set between the cathode inlet of the fuel stack and the mixing device A water-gas separator (JAD402-S type, purchased from Jingwei Machinery Factory, Fenghua City, Zhejiang Province) and a second plate heat exchanger (B5) arranged between the cathode outlet of the fuel stack and the first water-gas separator -SN-S type, available from Sweden SW...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap