Rotor structure for fault-tolerant permanent magnet motor

一种转子结构、永磁体的技术,应用在磁路形状/式样/结构、电动组件、磁路转动零部件等方向,能够解决增加增量成本、牺牲功率效率等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

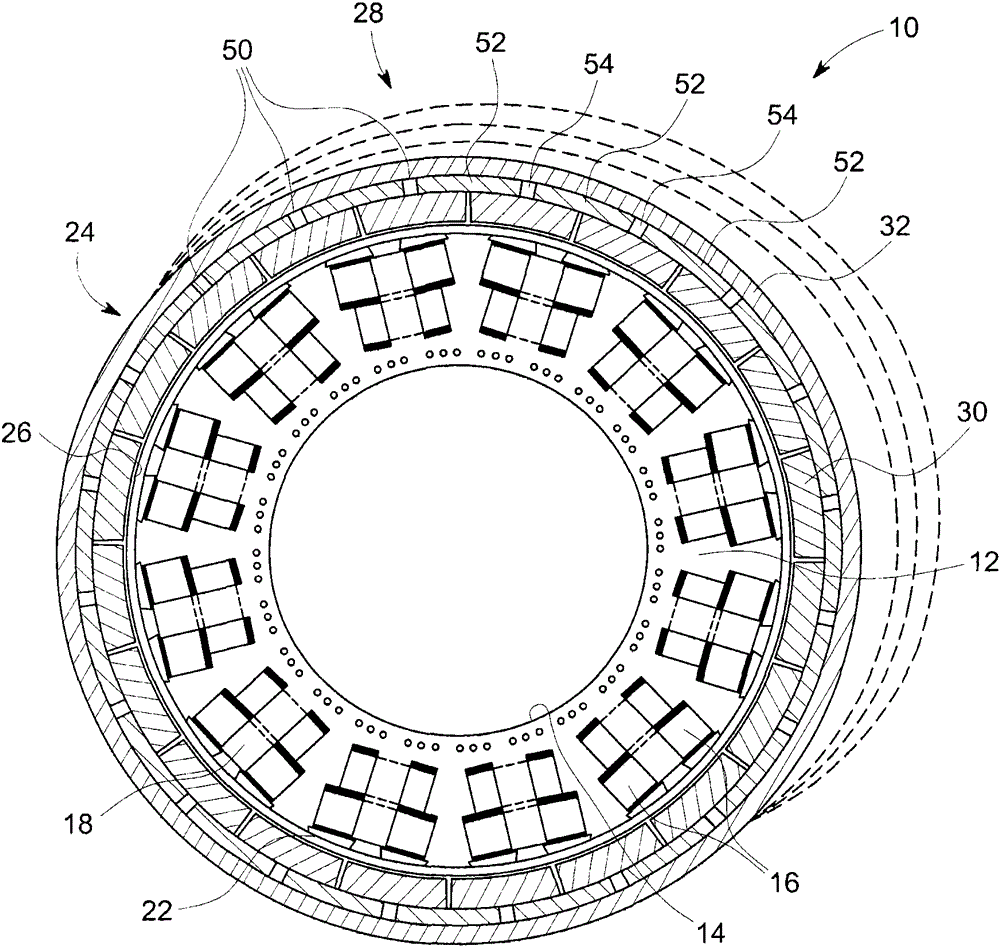

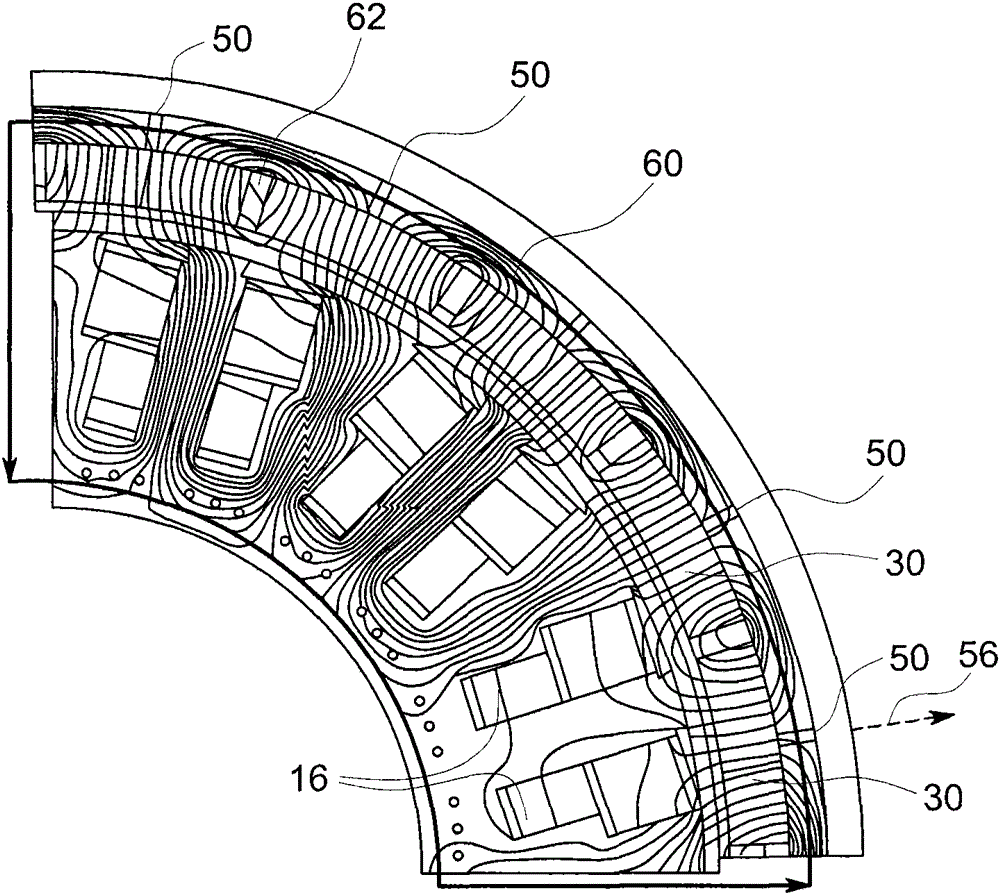

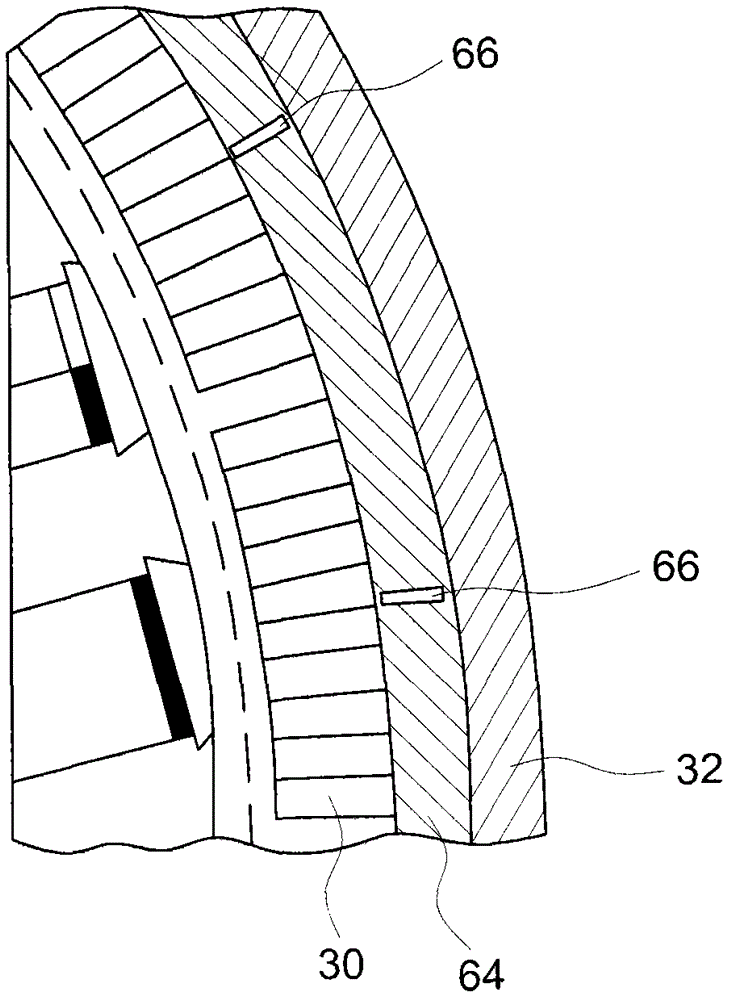

[0041] As discussed in more detail below, aspects of the present invention relate to fault-tolerant permanent magnet machines that may include fractional slot pitch concentrated windings. As used herein, the term "fault tolerance" refers to the magnetic separation and physical separation between various machine coils / phases, while reducing noise, torque ripple and harmonic flux components.

[0042] The inventors of the present invention propose an innovative and first-class method suitable for substantially reducing electromagnetic rotor losses generally associated with the frequency spectrum of the spatial harmonics of the fractional slot pitch concentrated winding. As mentioned before, this spectrum includes many asynchronous harmonics that do not add useful MMF. The proposed method can be advantageously configured to maximize the magnetoresistance encountered by asynchronous harmonics, while having substantially no effect on the useful or synchronous MMF components, thereby ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com