Spindle actuator

A technology for actuators and spindles, applied in the direction of non-mechanical drive clutches, clutches, transmissions, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

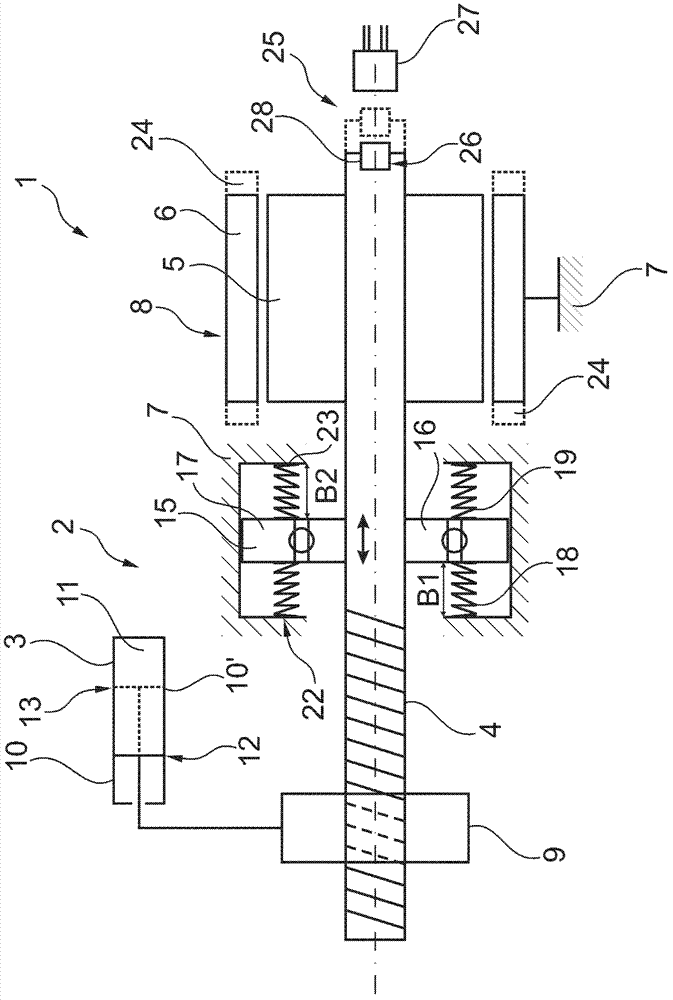

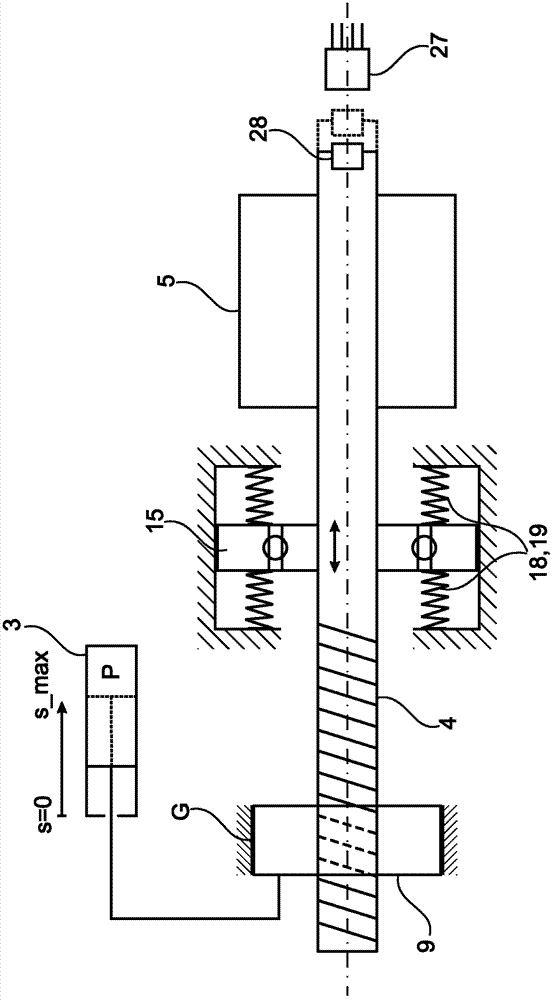

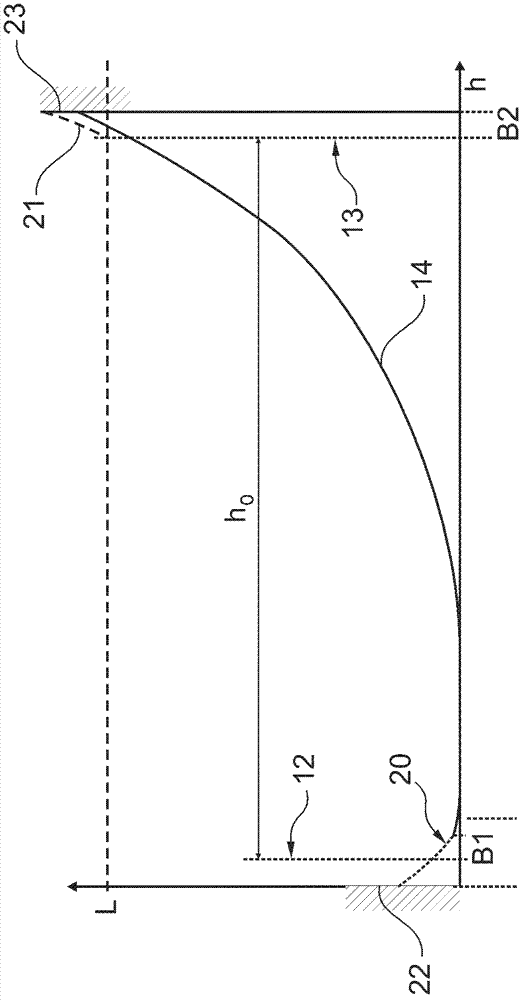

[0025] Figure 1A A spindle actuator 1 is shown schematically, here a hydrostatic actuator 2 with a master cylinder 3 which is connected via a pressure line to a slave cylinder, not shown. The spindle actuator 1 comprises a lead screw 4 driven by a rotor 5 of an electric motor 8 with its stator 6 arranged fixed to the housing on a housing 7 shown only in section. The lead screw 4 is now movable together with the motor bearing 15 described in detail below. The lead screw nut 9 is arranged on the lead screw 4 so as to be relatively rotatable, and the lead screw nut 9 is movably mounted on the housing 7 without relative torsion. The screw 4 and the screw nut 9 can be configured as a simple screw drive, a spherical screw drive or the like. The spindle and spindle nut can also be designed as a planetary rolling gear.

[0026] The lead screw nut 9 is axially fixedly connected with the piston 10 of the active cylinder 3, and when the electric motor 8 drives the lead screw 4, the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com