Abnormal shape forecasting method suitable for four-high rolling mill

A four-high rolling mill, non-state technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as unpredictable and inaccurate shape forecasting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

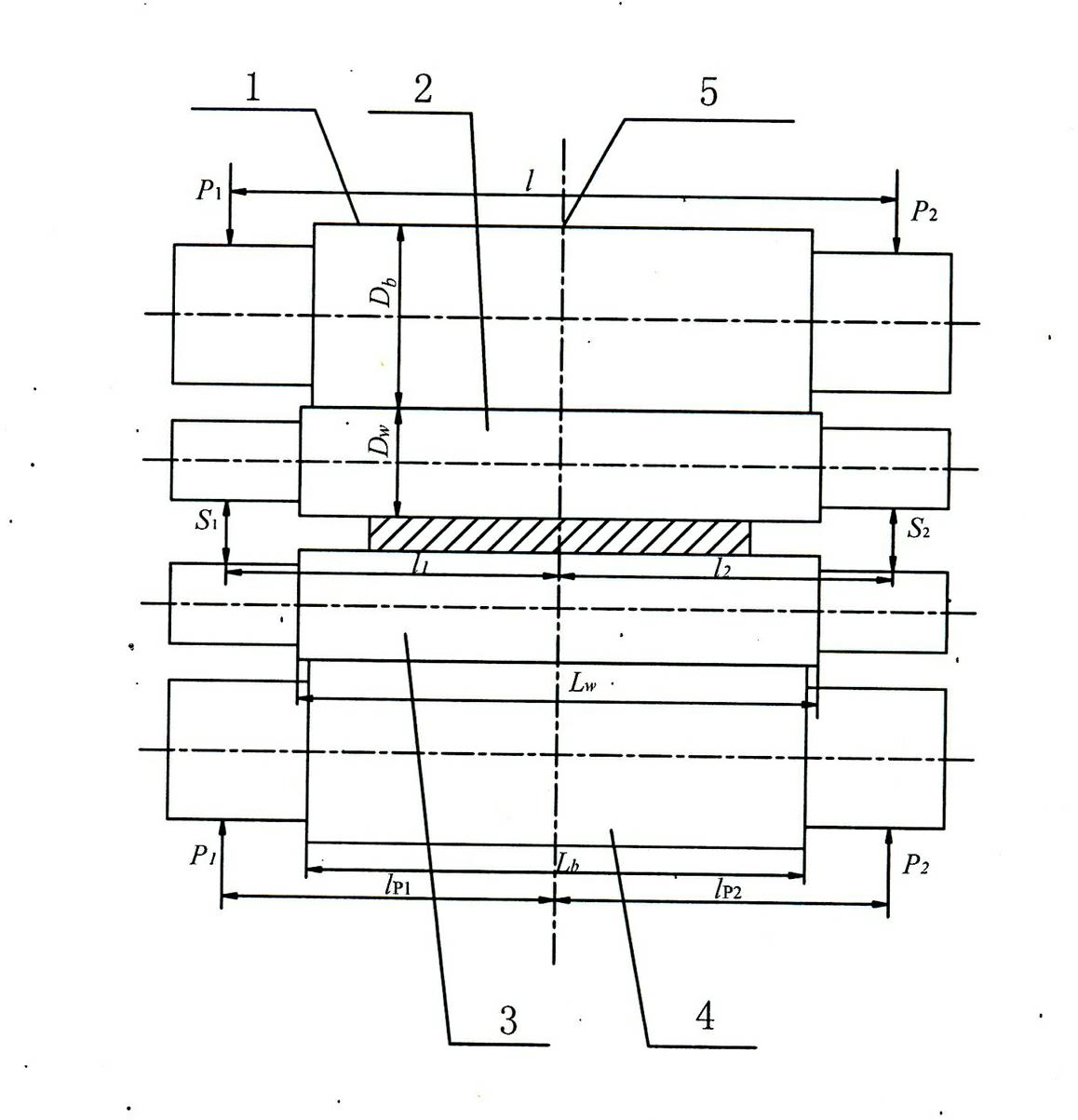

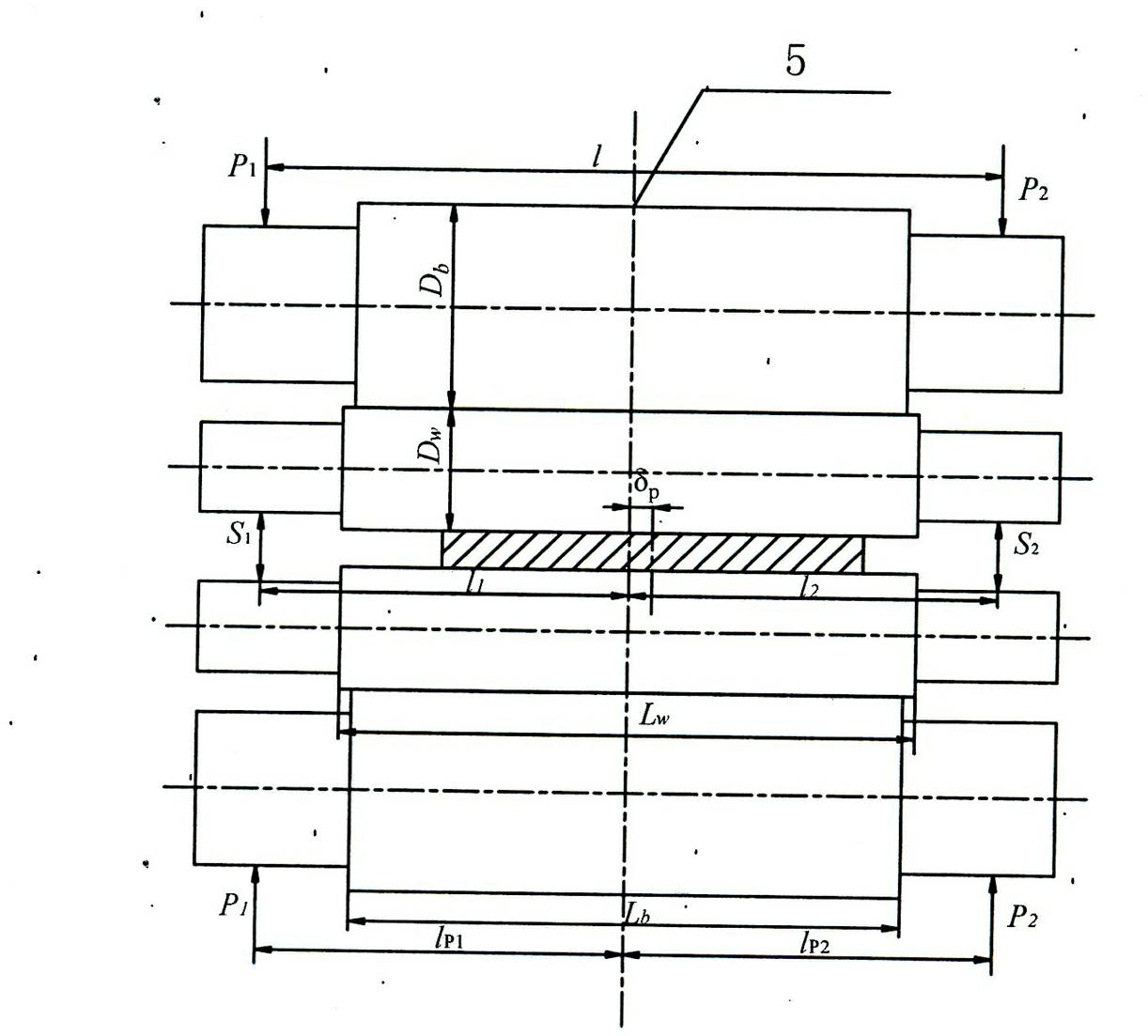

[0072] First, in step (1), the normal equipment parameters of the four-high rolling mill are collected, including the roll body lengths of the upper and lower work rolls and the upper and lower backup rolls , ;The distance between the upper and lower work roll bending cylinder ;Center distance between upper and lower supporting rollers ;

[0073] Then, in step (2), measure the deviation between the rolling centerline of the four-high mill and the roll centerline ;

[0074] Subsequently, in step (3), calculate the distances between the upper and lower support roll pressing screws and the rolling center line, respectively , , , ;The distance between the upper and lower work roll bending cylinder and the rolling center line , ;

[0075] Subsequently, in step (4), other abnormal equipment parameters of the four-high rolling mill are collected, mainly including the roll diameter of the upper and lower work rolls , ;Diameter of upper and lower support roller...

Embodiment 2

[0104] First, in step (1), the normal equipment parameters of the four-high rolling mill are collected, including the roll body lengths of the upper and lower work rolls and the upper and lower backup rolls , ;The distance between the upper and lower work roll bending cylinder ;Center distance between upper and lower supporting rollers ;

[0105] Then, in step (2), measure the deviation between the rolling centerline of the four-high mill and the roll centerline ;

[0106] Subsequently, in step (3), calculate the distances between the upper and lower support roll pressing screws and the rolling center line, respectively , , , ;The distance between the upper and lower work roll bending cylinder and the rolling center line , ;

[0107] Subsequently, in step (4), other abnormal equipment parameters of the four-high rolling mill are collected, mainly including the roll diameter of the upper and lower work rolls , ;Diameter of upper and lower support roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com