Paper delivery device and printer with same

A technology for a printer and a paper outlet, which is applied in the field of paper output devices and printers, can solve problems such as paper jams, printer damage, and deformation of printed characters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

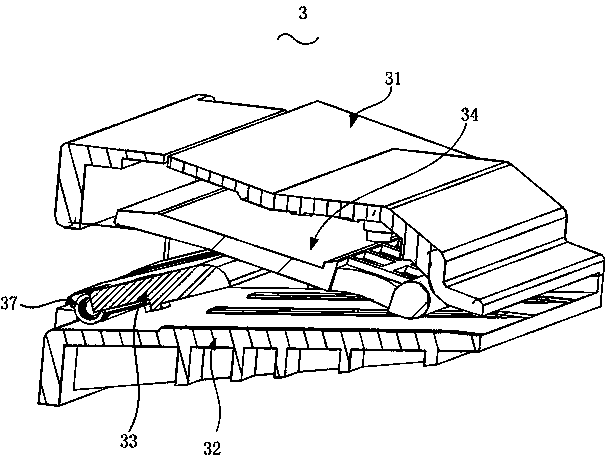

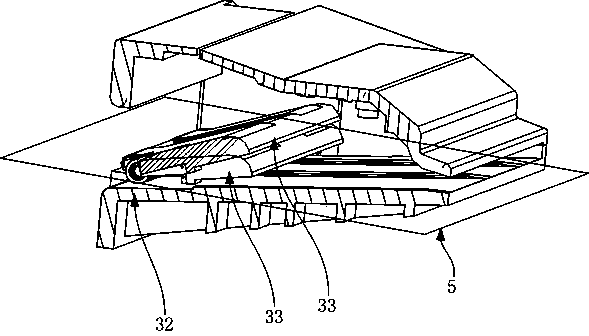

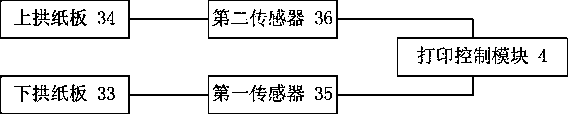

[0025] Such as Figure 1 to Figure 3 As shown, a paper output device 3 includes a housing 31 and a paper guide plate 32 arranged in the housing 31; the paper output device 3 has a paper inlet and a paper outlet, and the printing paper 5 passing through the print head, It enters from the paper inlet and outputs from the paper outlet; the paper outlet device 3 includes a lower arch cardboard 33, which is hinged to one end of the paper inlet of the paper guide plate 32, and the paper inlet of the paper outlet device 3, The area above the paper outlet and the lower arched cardboard 33 is a paper feeding channel, and the paper feeding channel is a curved output. The paper output device 3 includes a first sensor 35 , and the first sensor 35 correspondingly detects the swing of the lower arch cardboard 33 . The printing paper 5 is output in a curved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com