Cloth cuddling device of automatic pack loading machine

A charter and automatic technology, which is applied to the field of automatic charter loading and cloth grabbing devices, can solve the problems that cannot be automatically reset, need to be lifted manually by hand, limit the lifting height of the manipulator, and the space of the baler is limited, and achieves good trial effect and adaptability. Wide range of cloth bag height, safe and reliable effect of self-locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

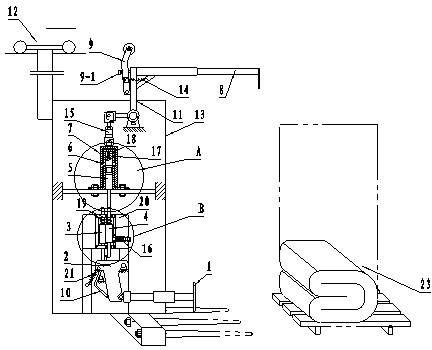

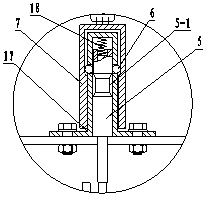

[0020] See figure 1 , The present invention includes a frame 13 and a bottom-up starting mechanism, a single-click lifting mechanism, a self-locking mechanism, and a ragging mechanism arranged on the frame, wherein the starting mechanism starts action under the action of an external force to drive the single-click lifting Mechanism action, click the jacking mechanism to drive the cloth-raising mechanism action, such as figure 1 When the cloth pulling mechanism shown is in the raised state, the cloth pulling lever is firmly locked by the self-locking mechanism.

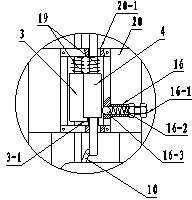

[0021] Still see figure 1 The starting mechanism includes a push rod 1, a starting lever 2, a slider lever 10 and a lever return tension spring 21. The start lever 2 is in a "T" shape, the fulcrum of the start lever is hinged with the frame, the push rod 1 laterally touches the lower end of the start lever, the upper end of the start lever touches the active slider 3, and the two ends of the lever return spring 21 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com