Parallel split type worm and gear sealing structure with independent oil inlet holes

A technology of worm gear and sealing structure, which is applied in the direction of engine sealing, gear transmission, belt/chain/gear, etc., can solve the problems of inability to control temperature rise, accumulative pitch error, pitch error, etc., and improve the friction state. , the effect of improving the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

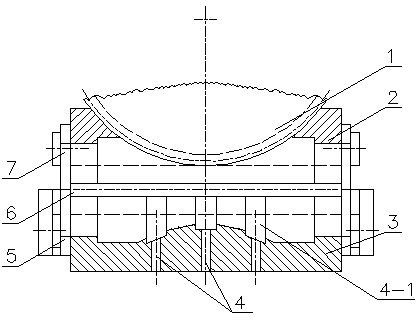

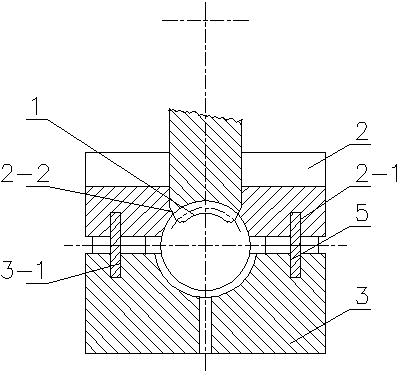

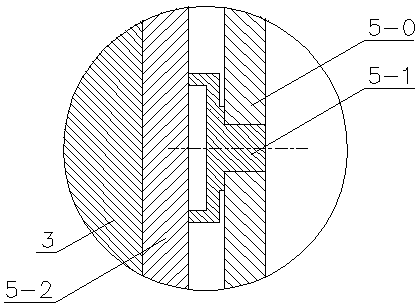

[0015] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 To attach Image 6 , the sealing structure described in this embodiment is composed of a worm wheel flange seal, a worm axial seal, a worm end face seal, and a worm radial seal, wherein the worm axial seal is formed by combining the middle seal block 2 and the outer seal block 3, The bonding surface of the middle seal block 2 and the outer seal block 3 is parallel to or slightly inclined to the axis of the worm gear, and the inclination angle is within 30 degrees. Both sides of the middle sealing block 2 and the outer sealing block 3 are respectively provided with the middle sealing groove 2-1 and the outer sealing groove 3-1, and the sealing strip 6 is embedded in the middle sealing groove 2-1 and the outer sealing groove 3-1 to form a seal A plurality of independent oil inlet holes 4 are distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com