Cathode current collector/connector for hall-heroult cell

A technology of current collectors and connectors, applied in the optimization field of cathode conductive rods/connecting rods, can solve the problems of complex copper/steel contacts, increased manufacturing costs, poor contact, etc., to achieve long-term reliable connection, increase service life, The effect of increasing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

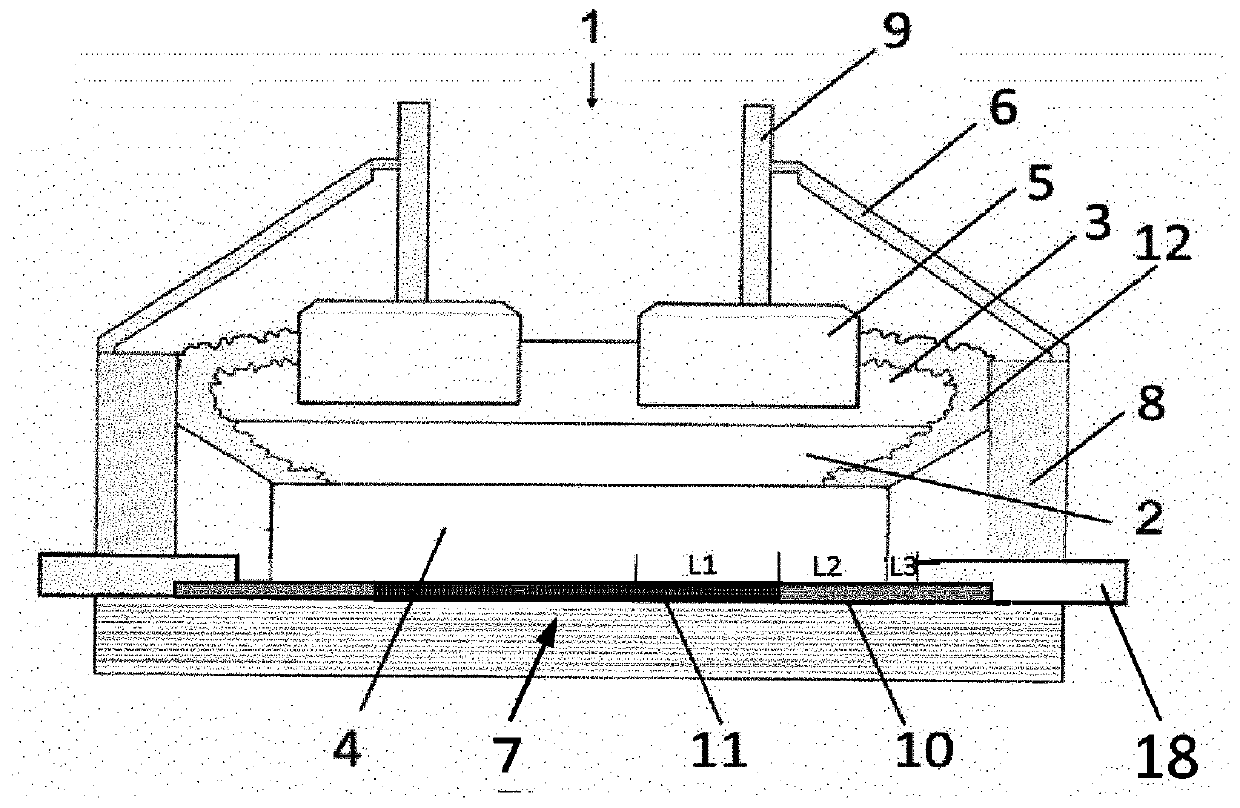

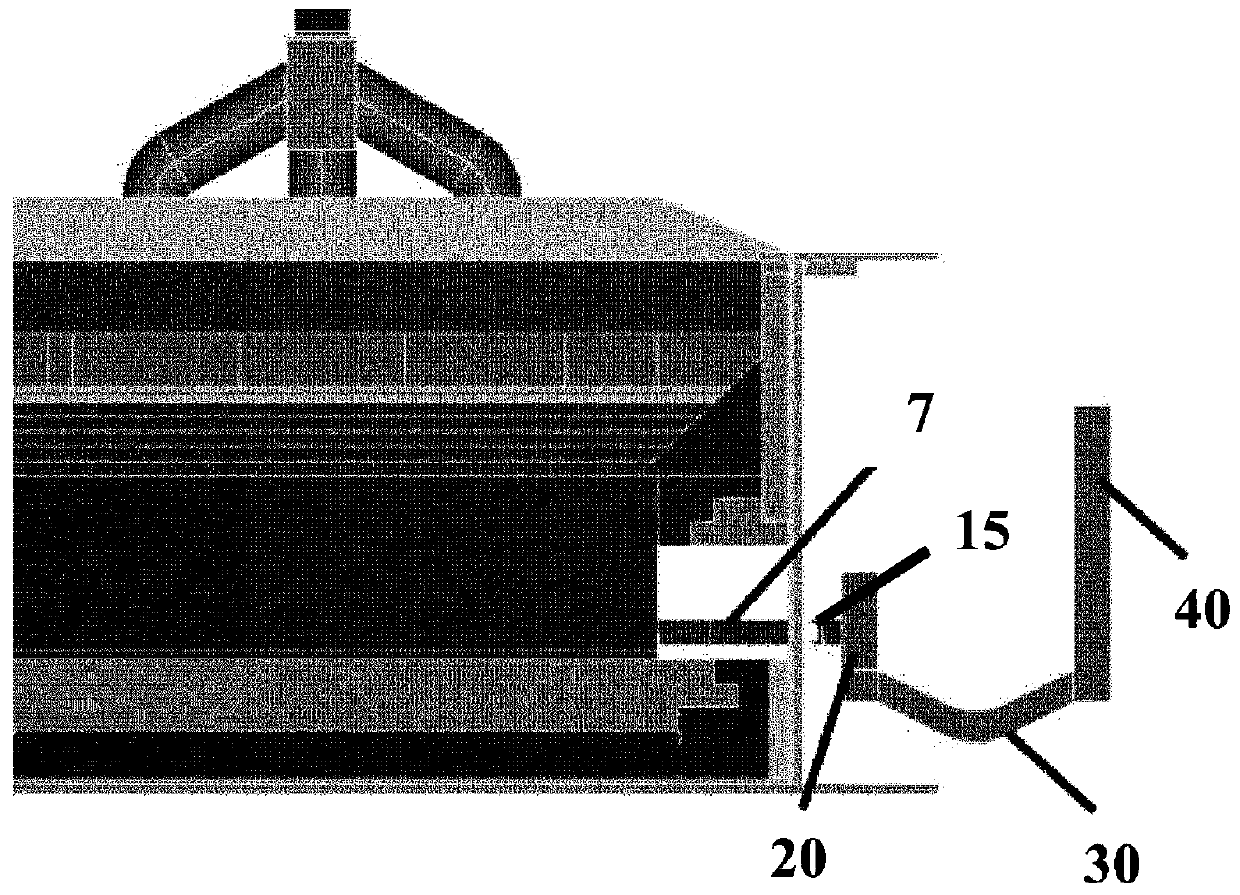

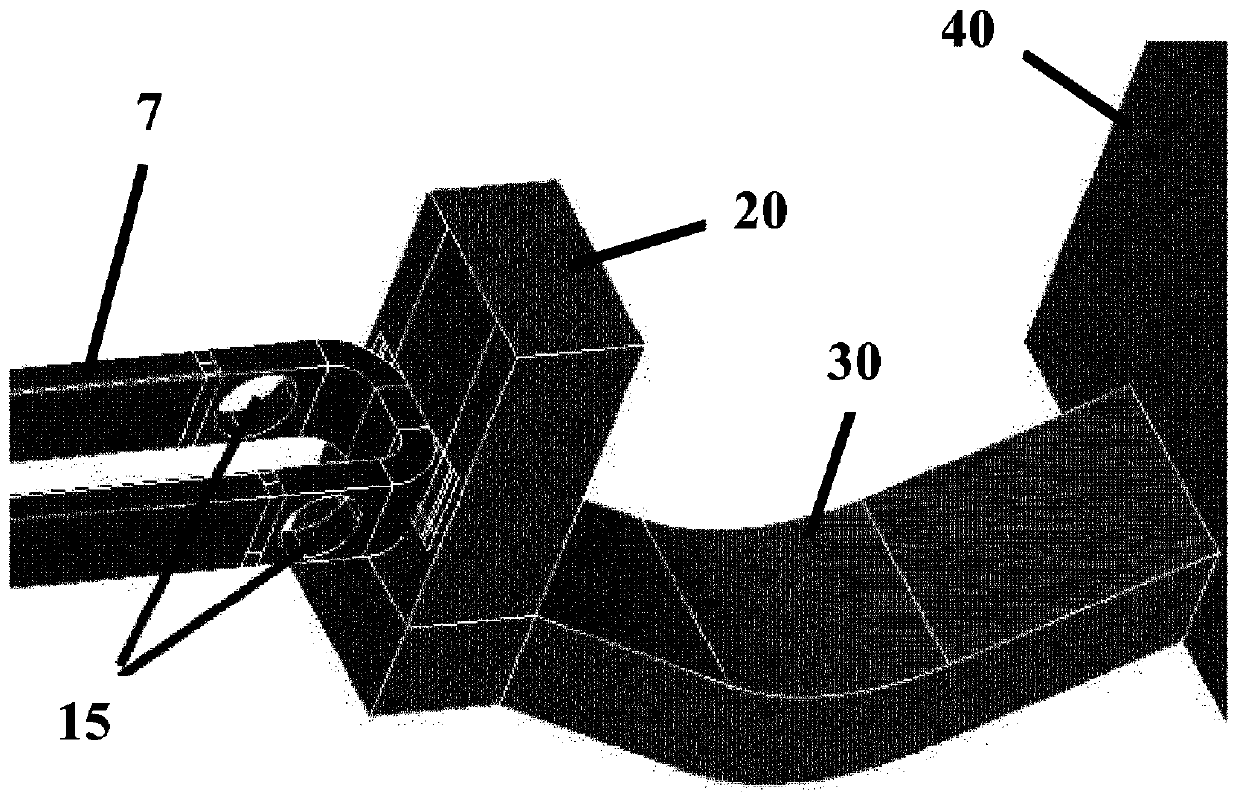

[0059] Figure 1 schematically shows a Hall-Eru cell 1 for the production of aluminum according to WO 2016 / 079605, the cell 1 comprising a carbon cathode cell bottom 4, a liquid cathode aluminum pool 2 on the carbon cathode cell bottom 4, an aluminum On top of the cell 2 is a fluoride (ie cryolite) based molten electrolyte 3 and a plurality of anodes 5 suspended in the electrolyte 3 containing dissolved alumina. Also shown are the cell cover 6 , the cathode current collector bar 7 leading according to the invention from the outside of the cell container 8 into the carbon cell bottom 4 , and the anode suspension rod 9 . It can be seen that the conductive rod 7 is divided into multiple regions. Region 10 is electrically insulating and region 11 consists of several layers. The molten electrolyte 3 is accommodated in a crust 12 of solidified electrolyte.

[0060] The basic consideration of WO 2016 / 079605 is that steel rods 18 of increased cross-sectional area are connected in ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com