Preparation method for Cu-based composite material based on negative thermal expansion particles

A negative thermal expansion, composite material technology, applied in the field of composite functional materials, can solve the problems of low thermal expansion coefficient, low thermal conductivity, and the performance of composite materials is very different, and achieves the effect of strong practicability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

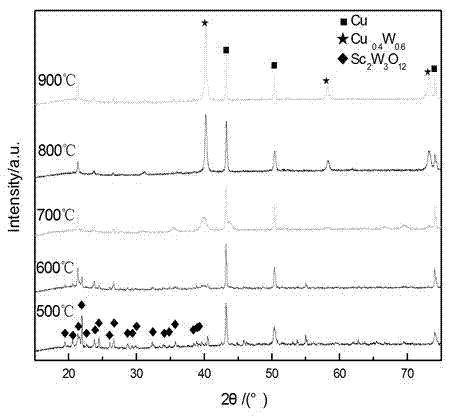

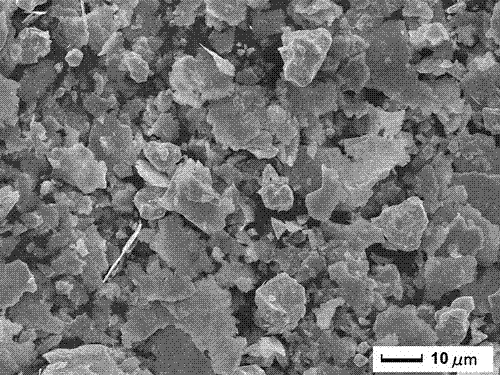

[0022] Weigh Sc 2 W 3 o 12 30 g Cu powder and 20 g Cu powder were initially mixed in a mortar, and then evenly divided into two ball mill jars, and absolute ethanol was added for wet ball milling. The ball mill time was set at 900 min, and the ball mill stopped every 30 min. After the ball milling is completed, take out the ball mill jar and put it in a drying oven for 12 hours at 80 °C, then take out the lump mixture, put it in a mortar and grind it for 60 minutes to get a uniform mixed powder; take 4 g of the mixed powder and put it into a cylindrical mold Oscillating and compacting, and keeping it under 10 MPa pressure for 3 minutes, demoulding and sampling to obtain a columnar sample with a diameter of 10 mm, and 5 samples were made by pressing tablets several times; these 5 samples were respectively heated at 500 °C , 600 ℃, 700 ℃, 800 ℃, 900 ℃, the heating rate was 5 ℃ / min, the holding time was 120 min, the flow rate of protective gas Ar was 1.5 ml / s, H 2 The flow rat...

Embodiment 2

[0025] Weigh Sc 2 W 3 o 1220 g Cu powder and 30 g Cu powder were initially mixed in a mortar, and then put into two ball mill jars evenly, adding absolute ethanol for wet ball milling, setting the ball milling time as 300 min, and the ball mill stopped every 30 min. After the ball milling is completed, take out the ball mill jar and put it in a drying oven for 12 hours at 80 °C, then take out the block mixture, put it in a mortar and grind it for 60 minutes to obtain a mixed powder; take 4 g of the mixed powder and add it to a cylindrical mold for oscillation Compacted and held at a pressure of 10 Mpa for 3 min, demolded and sampled to obtain a columnar sample with a diameter of 10 mm. The sample was sintered at 600 °C in a vacuum tube furnace with a heating rate of 5 °C / min and a holding time of 120 °C. min, the flow rate of protective gas Ar is 1.5 ml / s, H 2 The flow rate is 0.3 ml / s, and Sc is produced with furnace cooling 2 W 3 o 12 A copper-based composite material ...

Embodiment 3

[0028] Weigh Sc 2 W 3 o 12 Mix 30 g Cu powder and 20 g Cu powder, divide them into two ball mill tanks evenly, add absolute ethanol for wet ball milling, set the ball milling time to 900 min, stop the ball mill for 15 min every 30 min, and take out the ball mill after the ball milling is completed Put the can into a drying oven at 80 °C for 12 h, then take out the block mixture, put it into a mortar and grind for 60 min to obtain a uniformly mixed powder; take 4 g of the mixed powder and add it to a cylindrical mold for vibration and compaction, and grind it at 10 Mpa After being kept under pressure for 3 min, samples were removed from the mold to obtain a columnar sample with a diameter of 10 mm. The sample was sintered at 600 °C in a vacuum tube furnace with a heating rate of 5 °C / min and a holding time of 120 min. The flow rate is 1.5 ml / s, H 2 The flow rate is 0.3 ml / s, and Sc is produced with furnace cooling 2 W 3 o 12 A copper-based composite material with a mass c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com