Rotary motor

A technology of rotating electrical machines and conductive components, which is applied in the directions of motors, electric vehicles, electrical components, etc., can solve the problems of the inner side of the casing falling down, increasing the working time, etc., to achieve the effect of easy tightening operation and prevention of insulation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

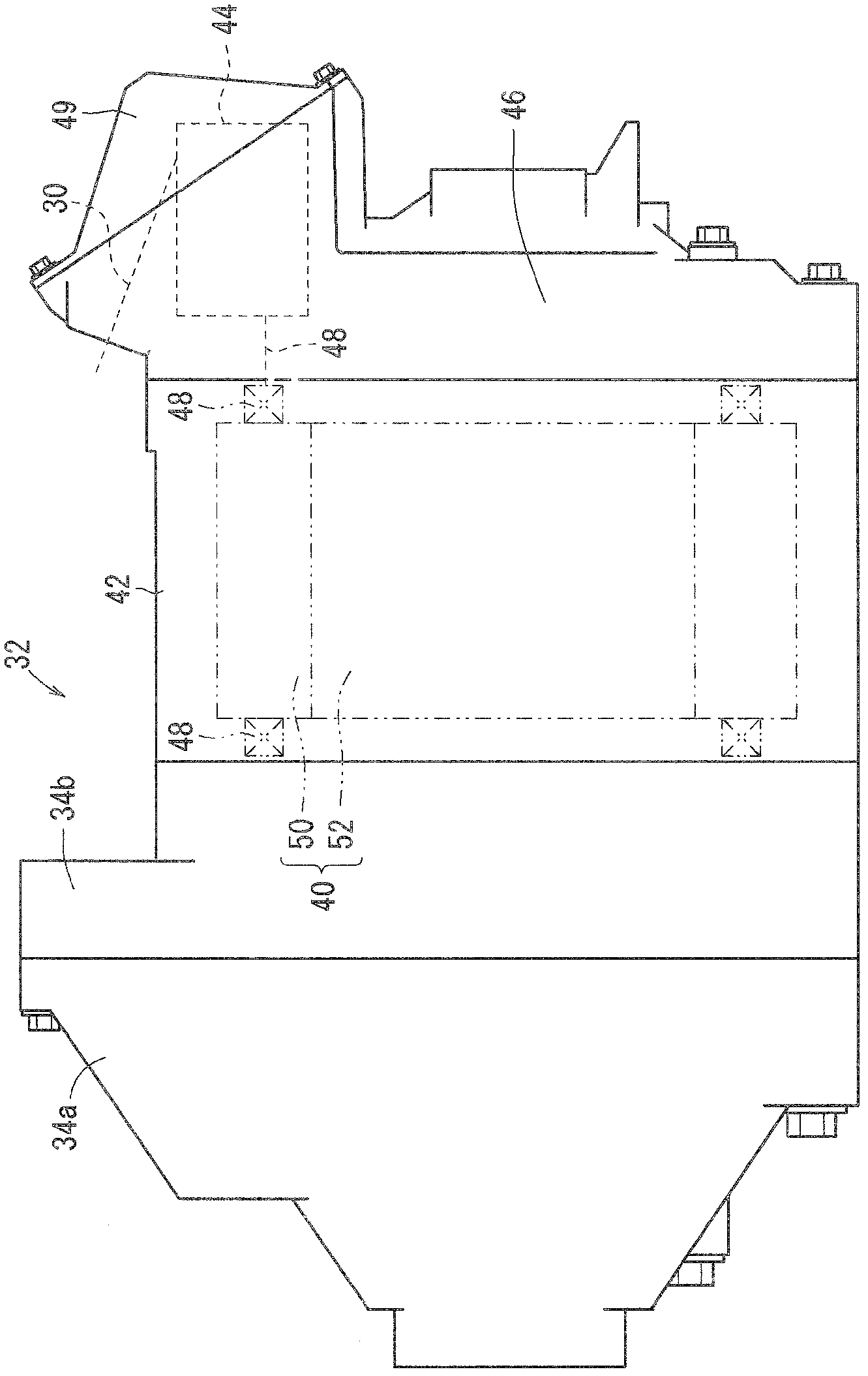

[0054] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

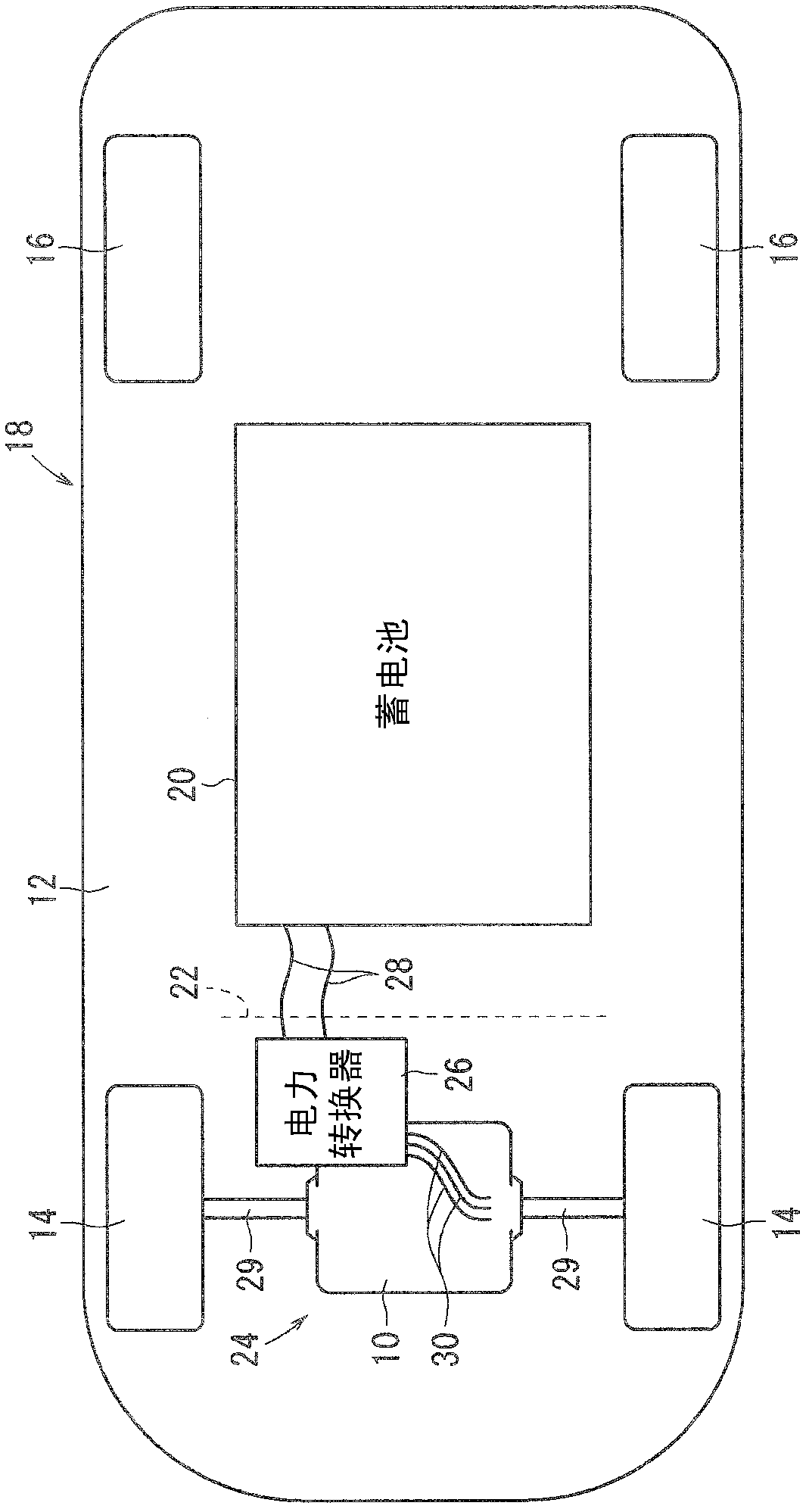

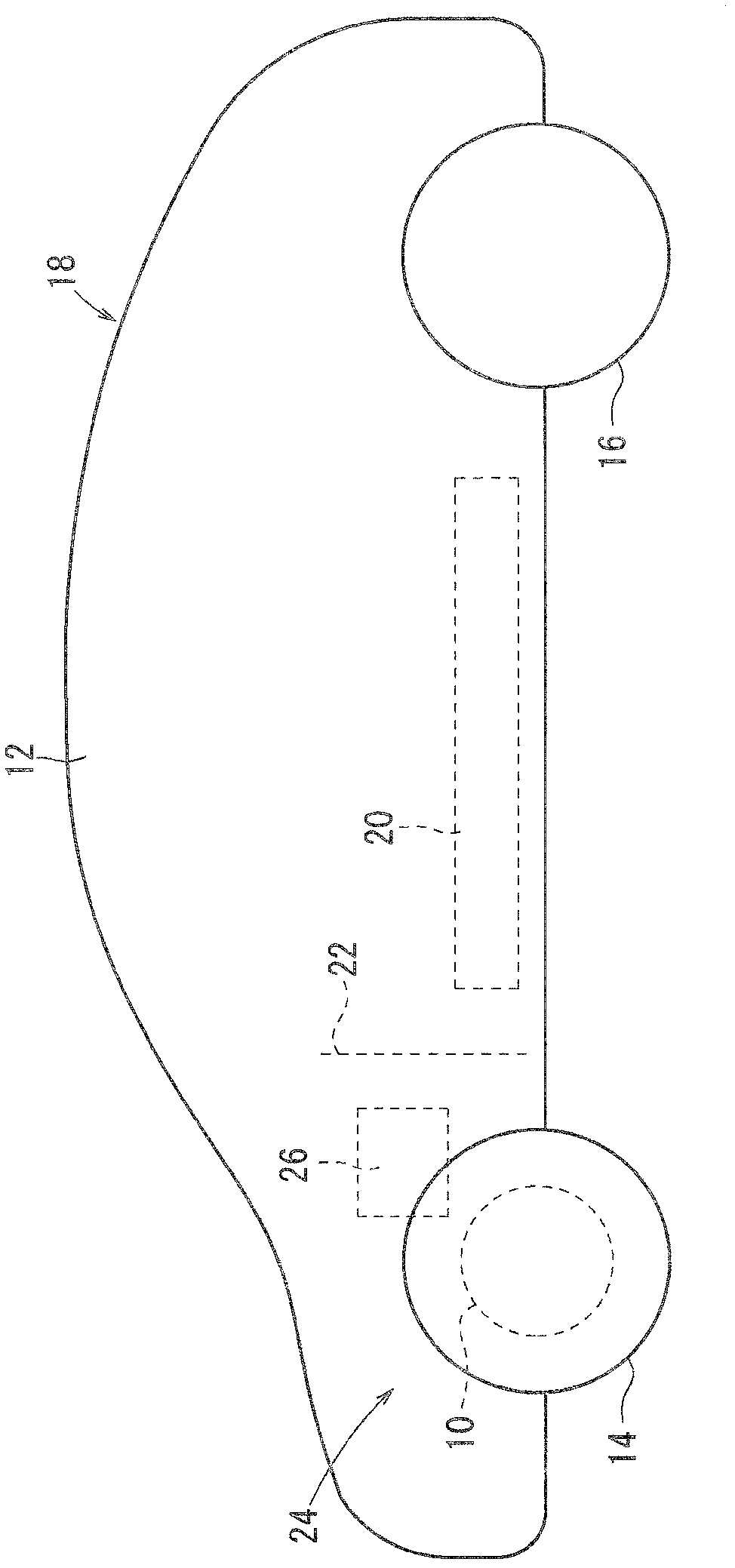

[0055] figure 1 Indicates that the rotating electric machine 10{of this embodiment functions as a motor or a generator. Hereinafter, it is called a motor for easy understanding. } A schematic plan view of a four-wheeled vehicle 18 (electric vehicle) including front wheels 14 and rear wheels 16 mounted on the vehicle body 12 . figure 2 A schematic side view of vehicle 18 is shown.

[0056] A battery 20 is disposed under a floor under unillustrated seats of the vehicle 18 . Motor 10 and power converter 26 are mounted in motor room 24 of vehicle 18 forward of dashboard lower panel 22 , and the rotation of the rotation shaft of motor 10 is transmitted to axle 29 that rotates left and right front wheels 14 .

[0057] Two DC power lines 28 are connected between a power converter 26 mounted vertically above the motor 10 and the battery 20 , and three AC three-phase power l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com