Patents

Literature

50results about How to "Avoid working hours" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

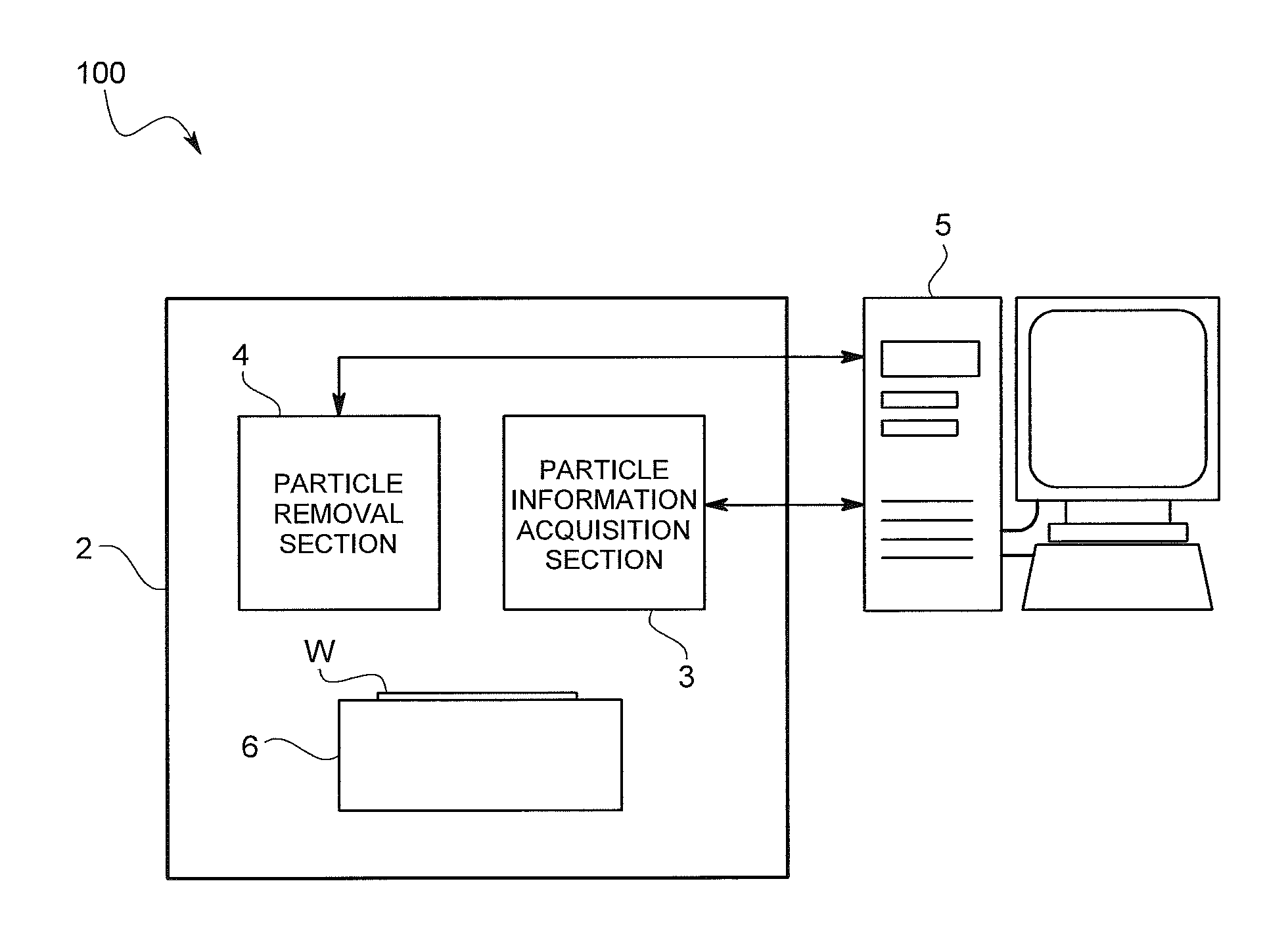

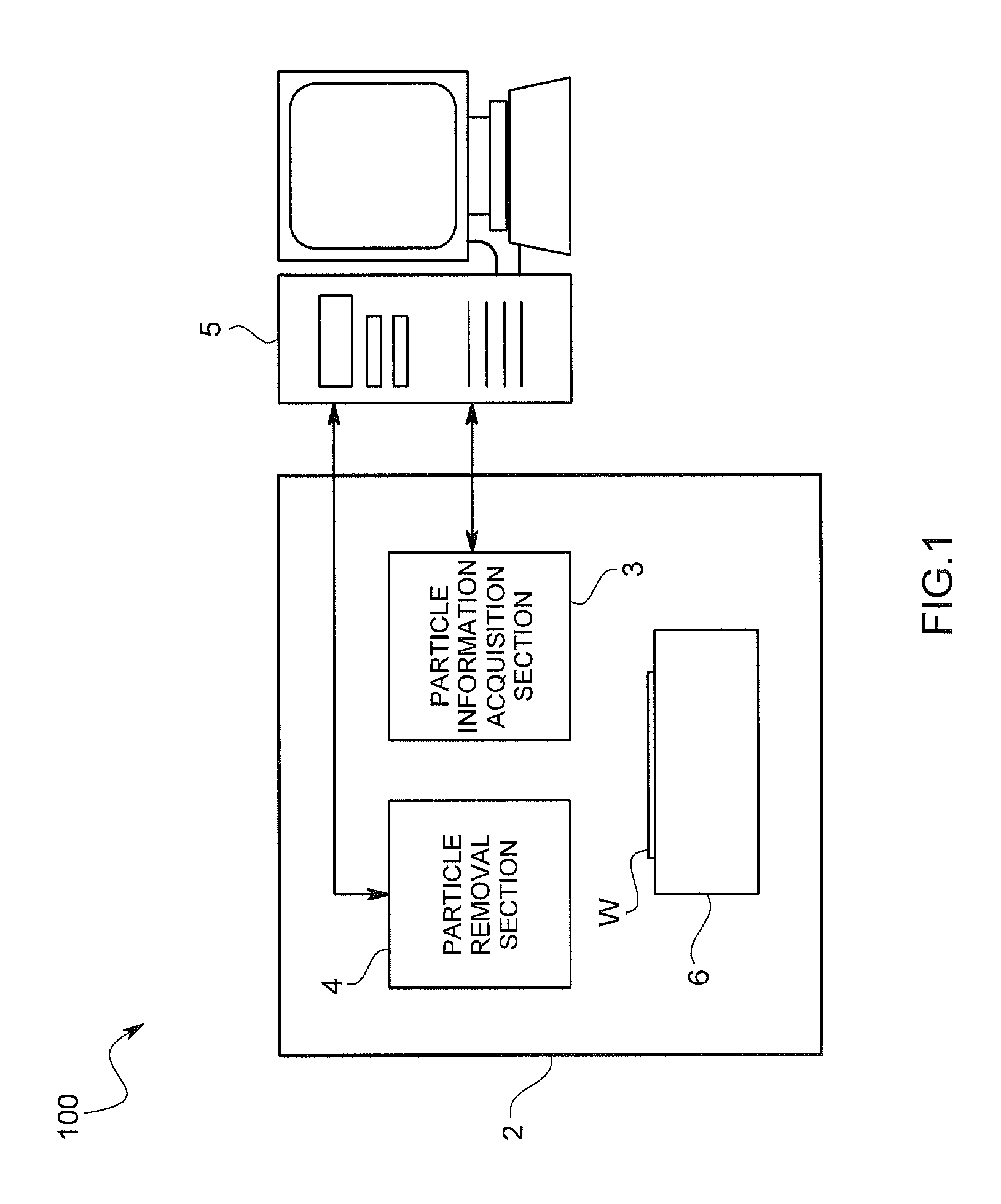

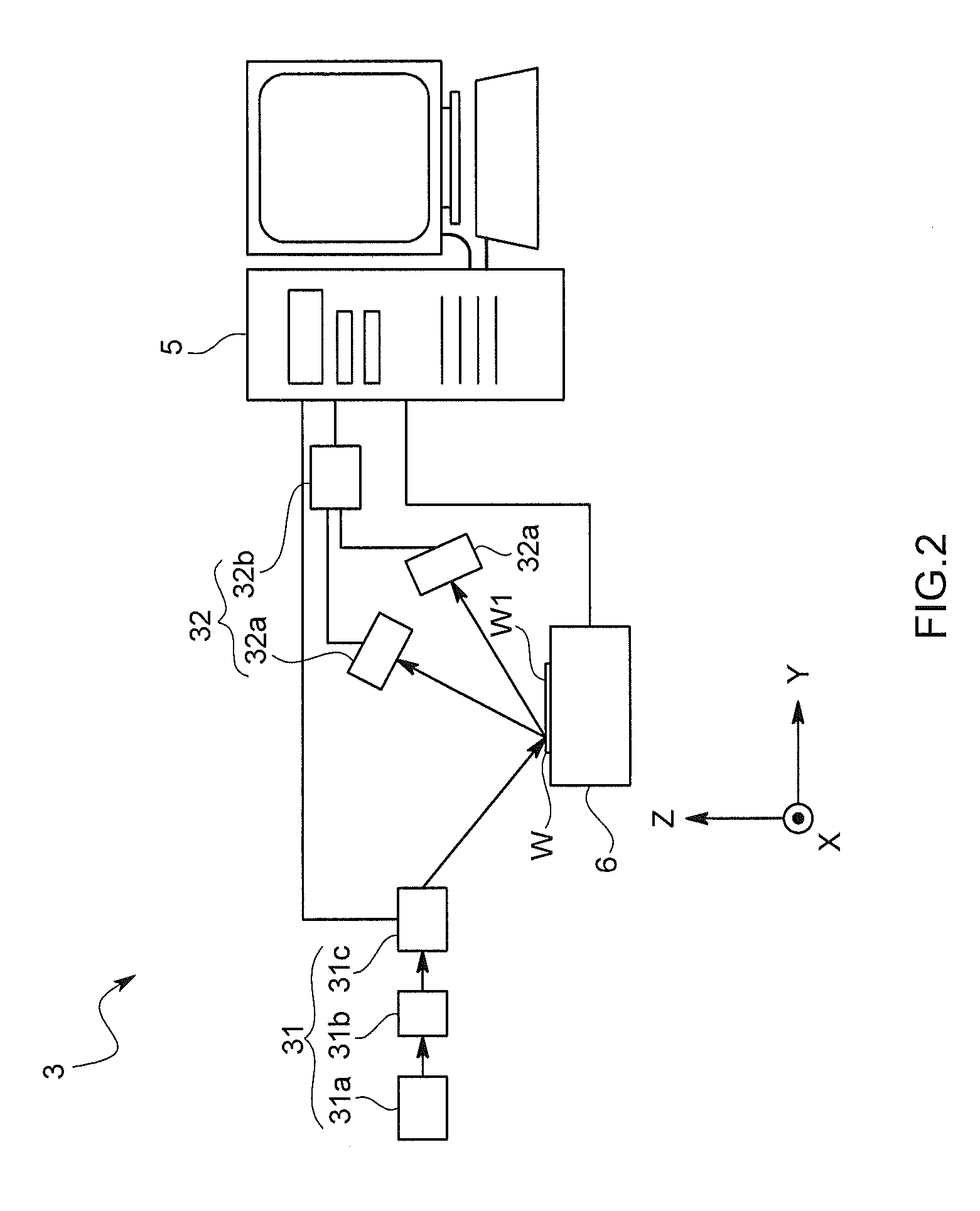

Particle inspection and removal apparatus and particle inspection and removal program

InactiveUS20100229902A1Reduce workloadEliminate measurement errorsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingParticle physicsInformation acquisition

The present invention is to lessen work burden on a user, to eliminate determination error, to prevent a substrate from being damaged, and to prevent prolonged working time by automatically determining whether or not a particle to be removed is present. A particle inspection and removal apparatus of the present invention includes a particle information acquisition section acquiring particle information on a particle adhering onto a substrate surface, a particle removal section removing the particle adhering onto the substrate surface, a comparison section comparing a threshold set for each of regions of the substrate surface with the particle information on each of the region obtained by the particle information acquisition section, and a particle removal control section controlling the particle removal section to remove the particle on the substrate surface based on a comparison result of the comparison section.

Owner:HORIBA LTD

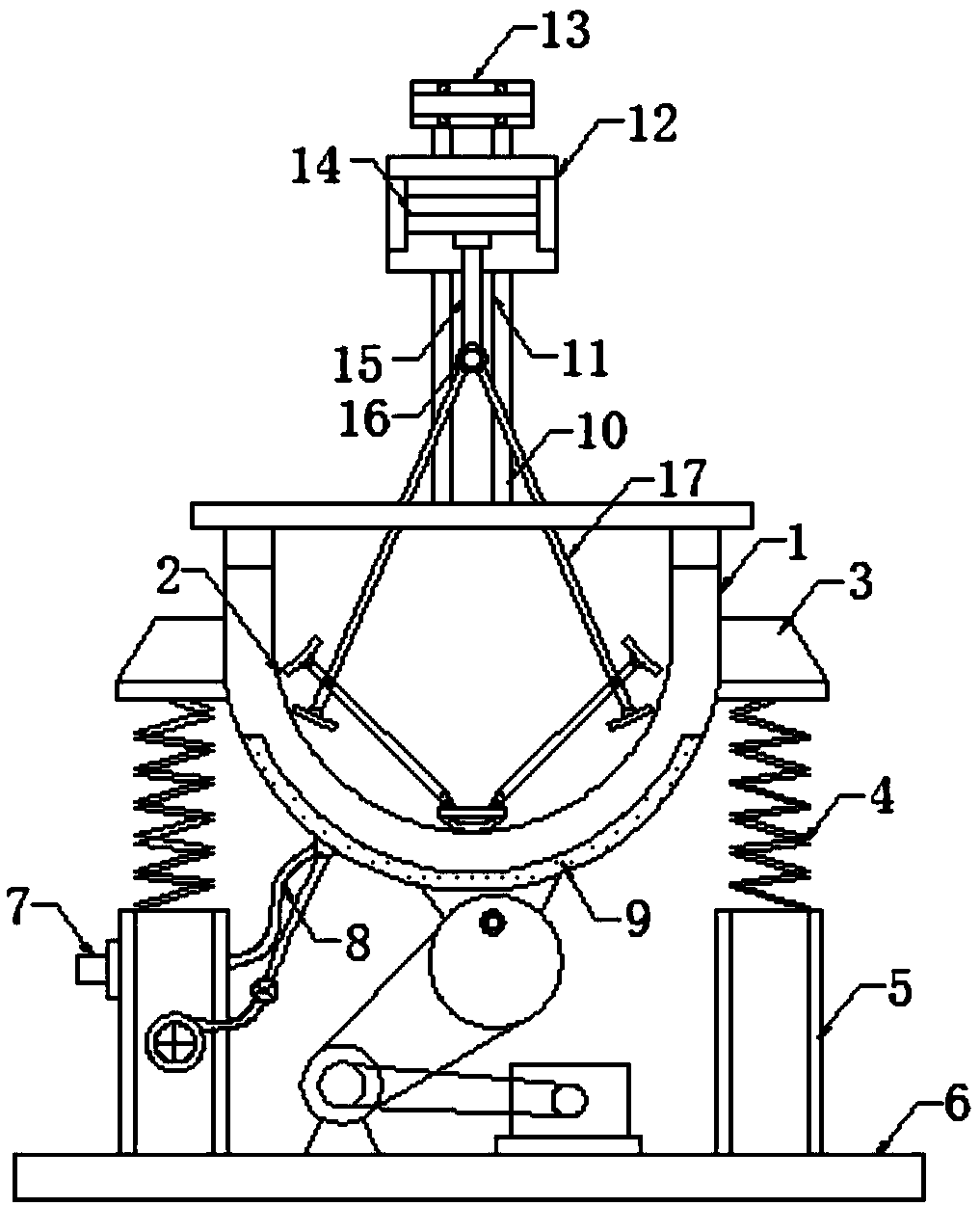

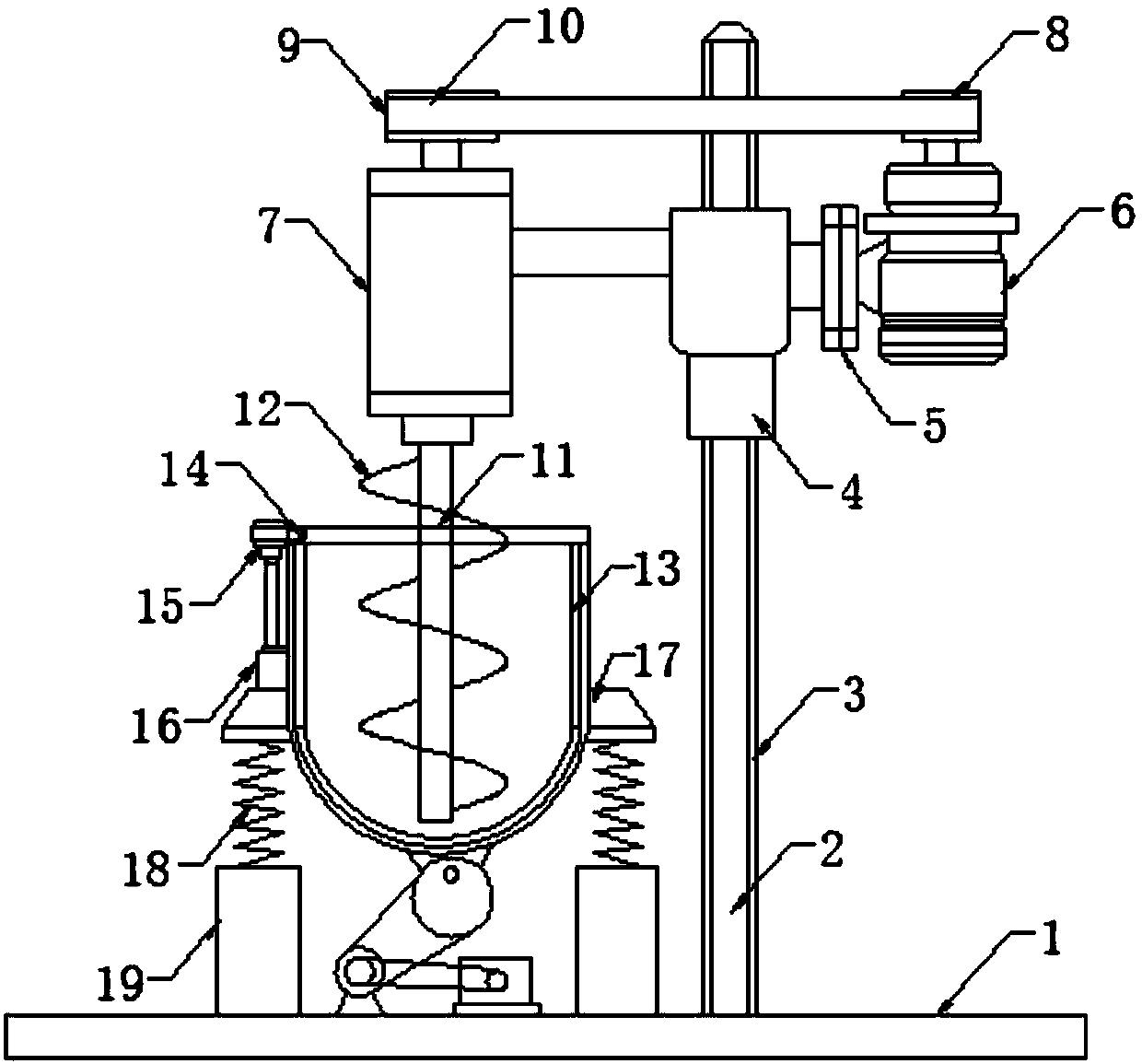

High efficiency automatic wok

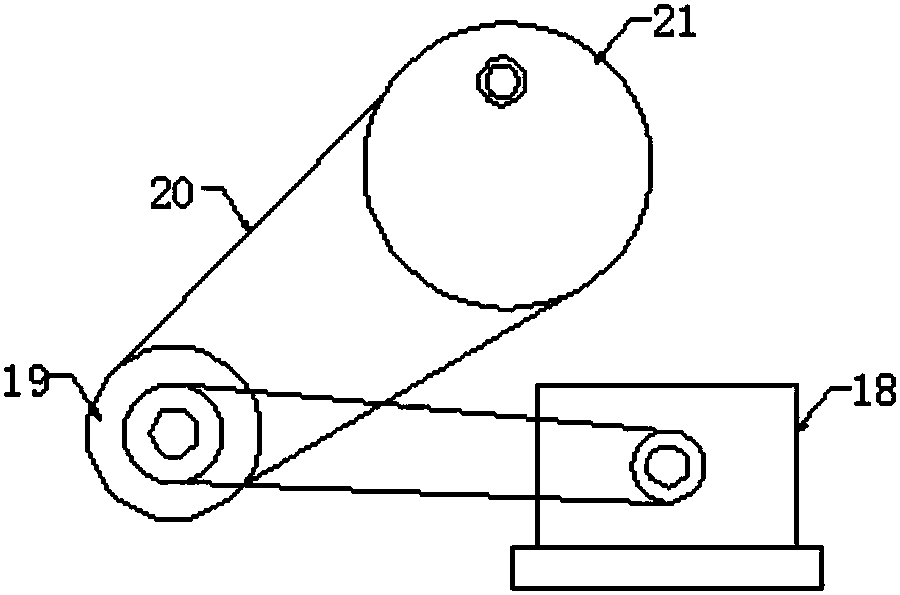

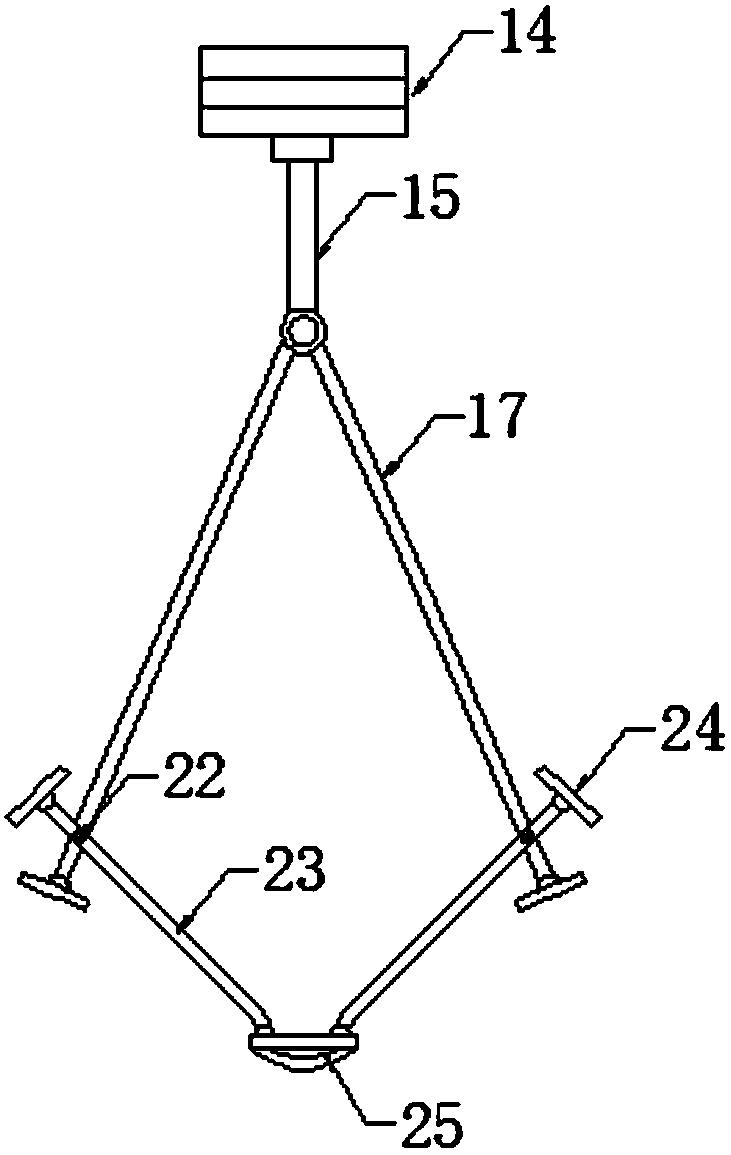

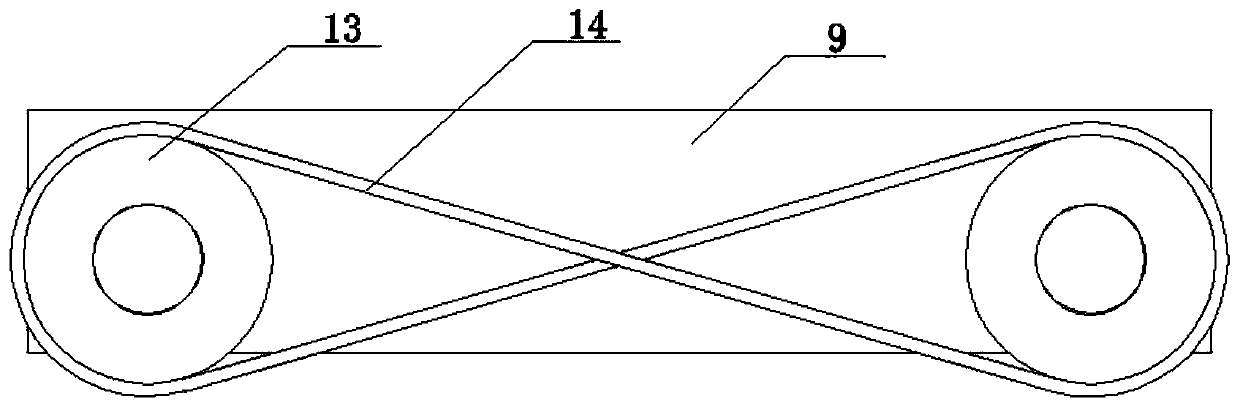

InactiveCN107595115AStir fry fullySpeed up the heating evenlyCooking insertsCooking vessel supportDrive wheelDrive motor

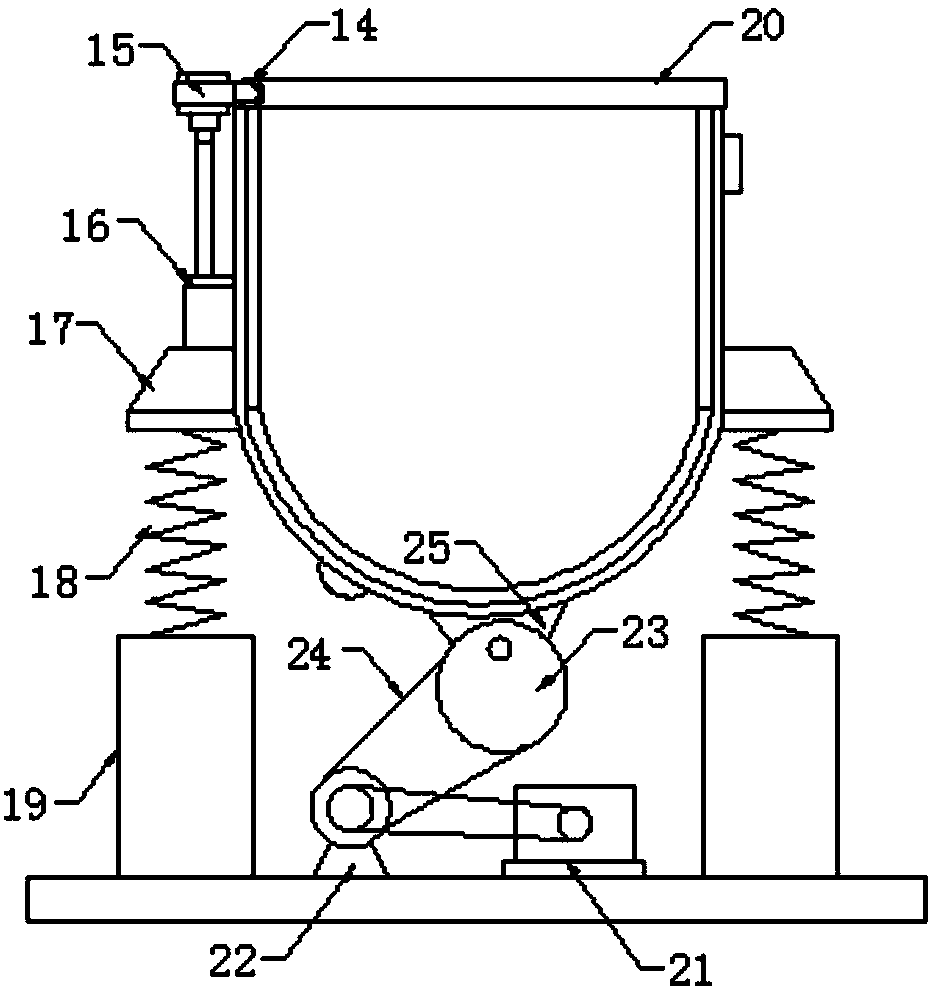

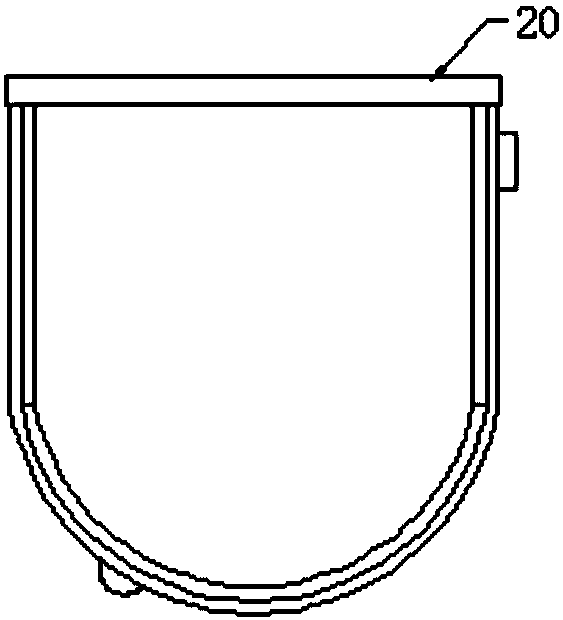

The invention discloses a high efficiency automatic wok, comprising an outer wok body, an inner wok body, ear plates, buffer springs, support seats, a base, a gas inlet, an air inlet pipe, a gas stovehead, a locating frame, a sliding rail, a sliding seat, a reciprocating motor, a rotary motor, a main shaft, a movable shaft ring, main stirring rods, a drive motor, a driving wheel, a driving belt,an eccentric wheel, connecting pieces, and the like. The high efficiency automatic wok is compact in structure, realizes a function of automatically stir-frying food, reduces the labor intensity of acook, and enables the food in the wok to be more evenly heated; a wok body is vibrated and swung, so that the speed of evenly heating the food in the wok body is accelerated, and more thorough stir-frying is realized; the phenomena that materials are stuck on the inner wall of the wok body and the food on the wok wall can not be fully stir-fried can be effectively avoided by means of a brush headwhile the stir-frying speed is accelerated; therefore, the food in the wok body is enabled to be more evenly stir-fried, the working time is effectively shortened, the working efficiency is increased,and the use of manpower is effectively reduced.

Owner:WENZHOU CHUYING TECH CO LTD

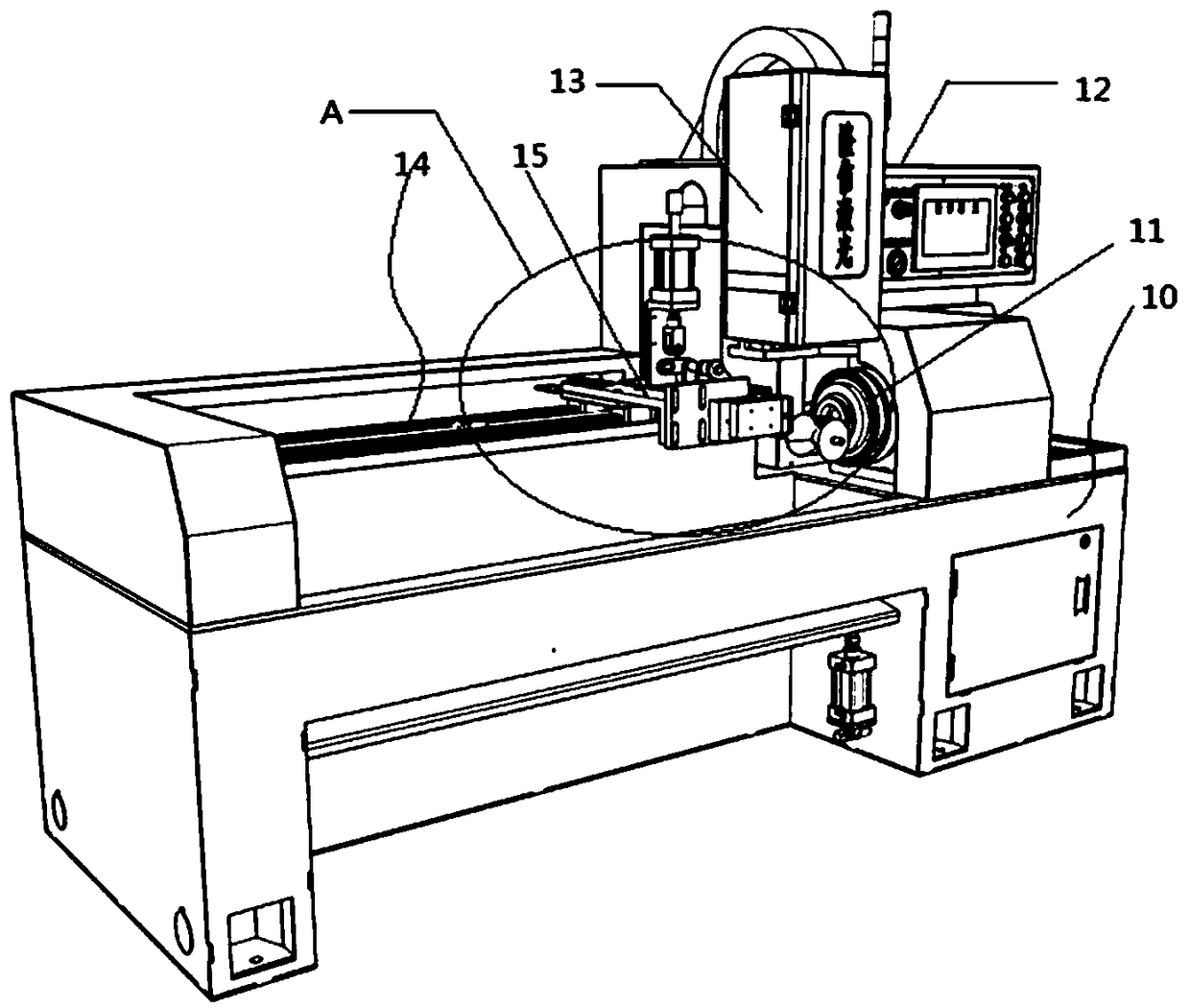

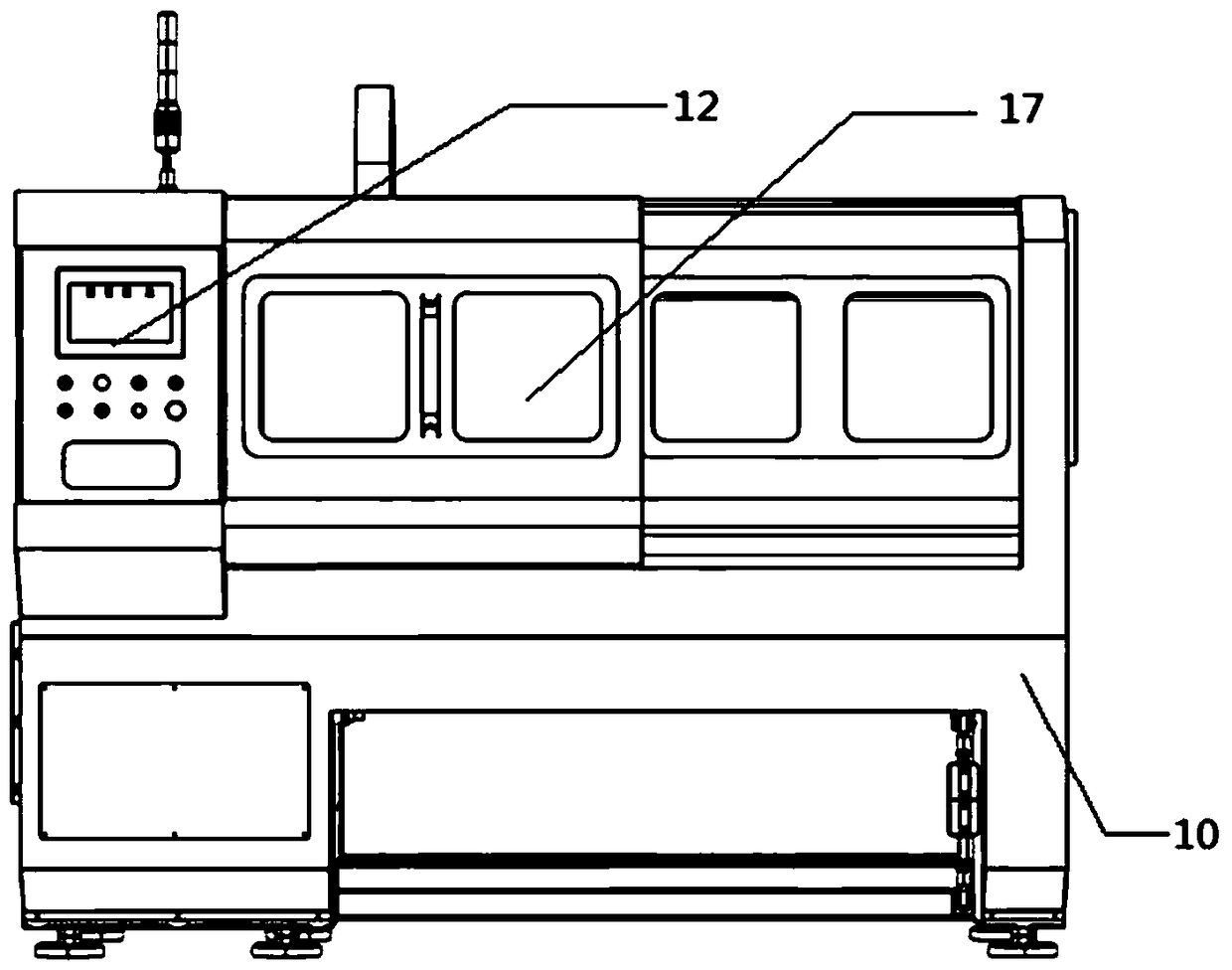

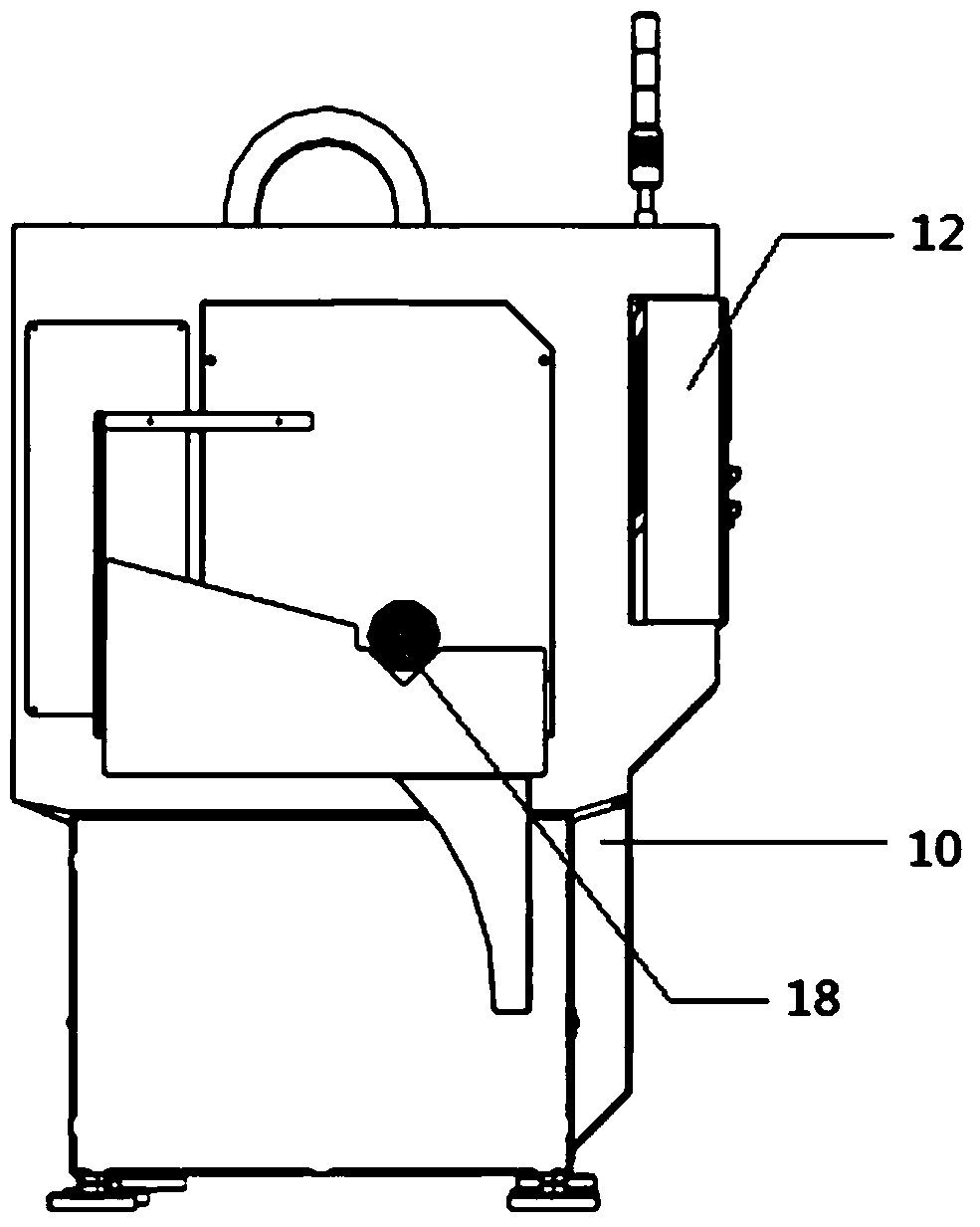

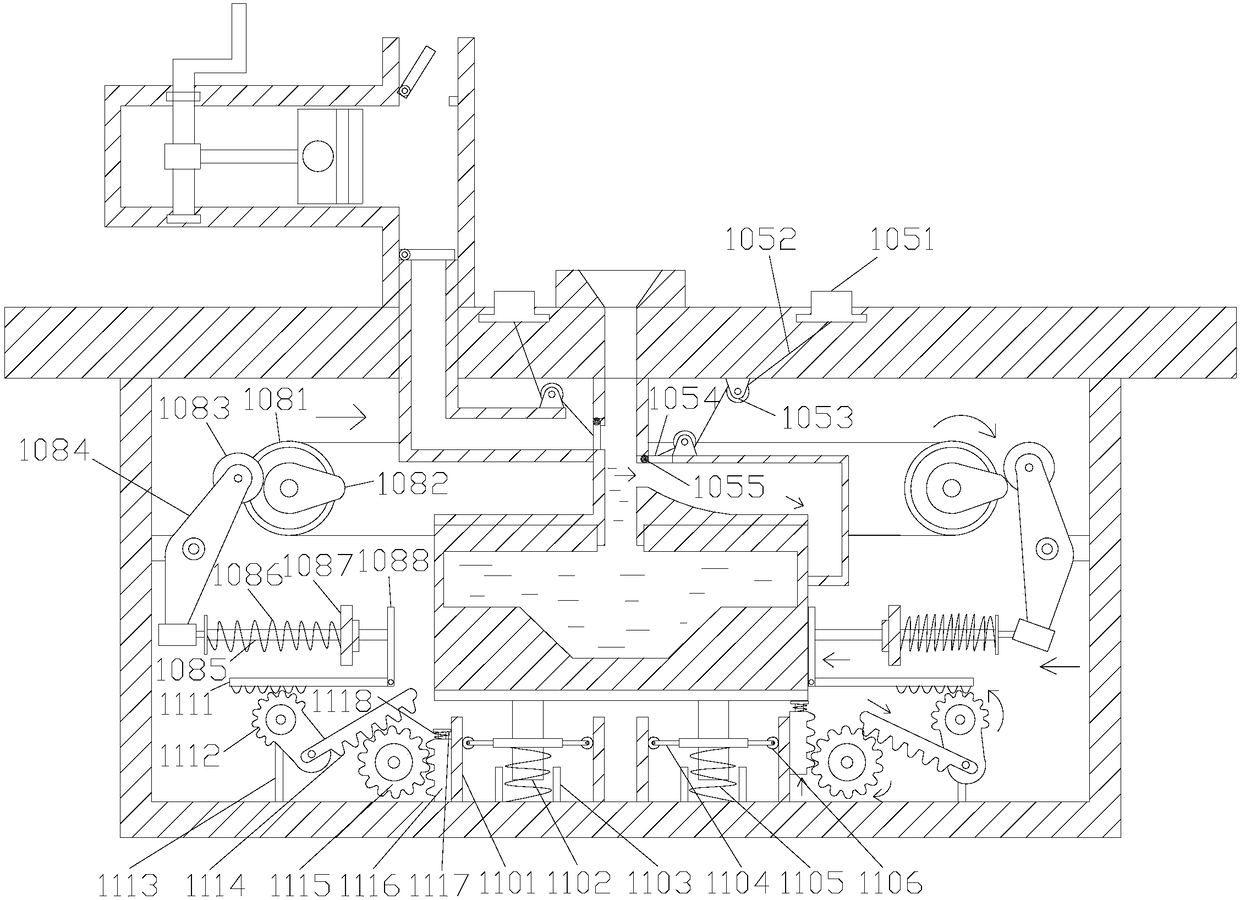

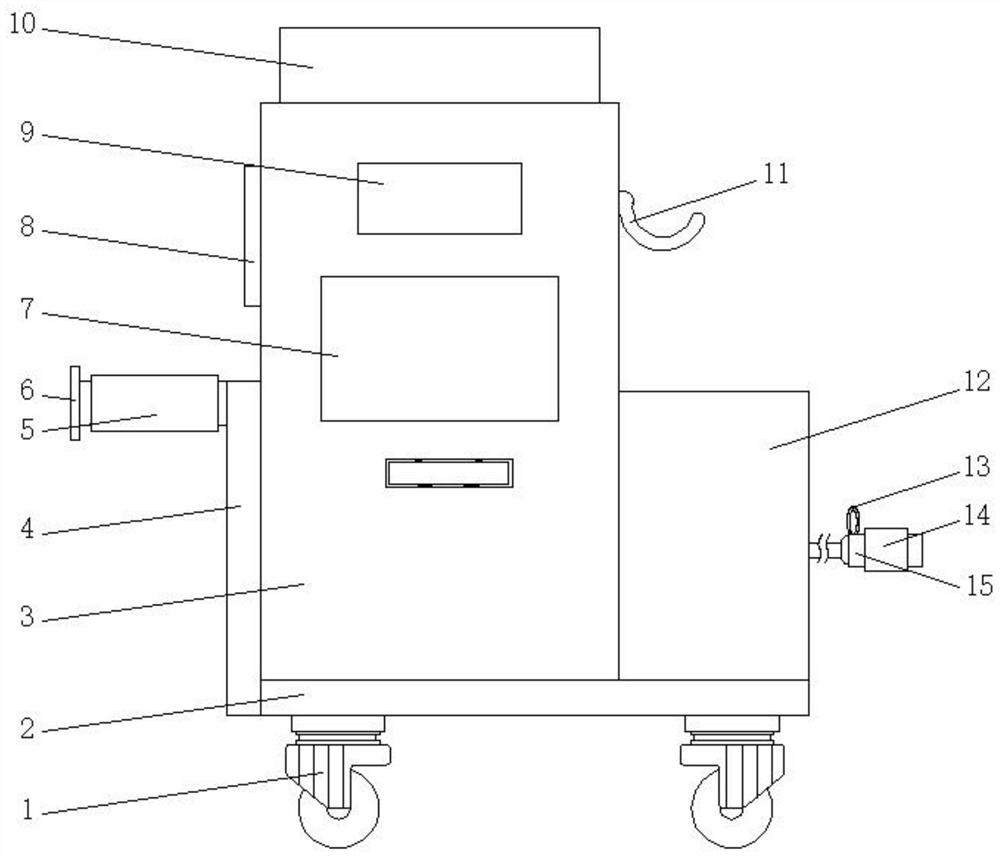

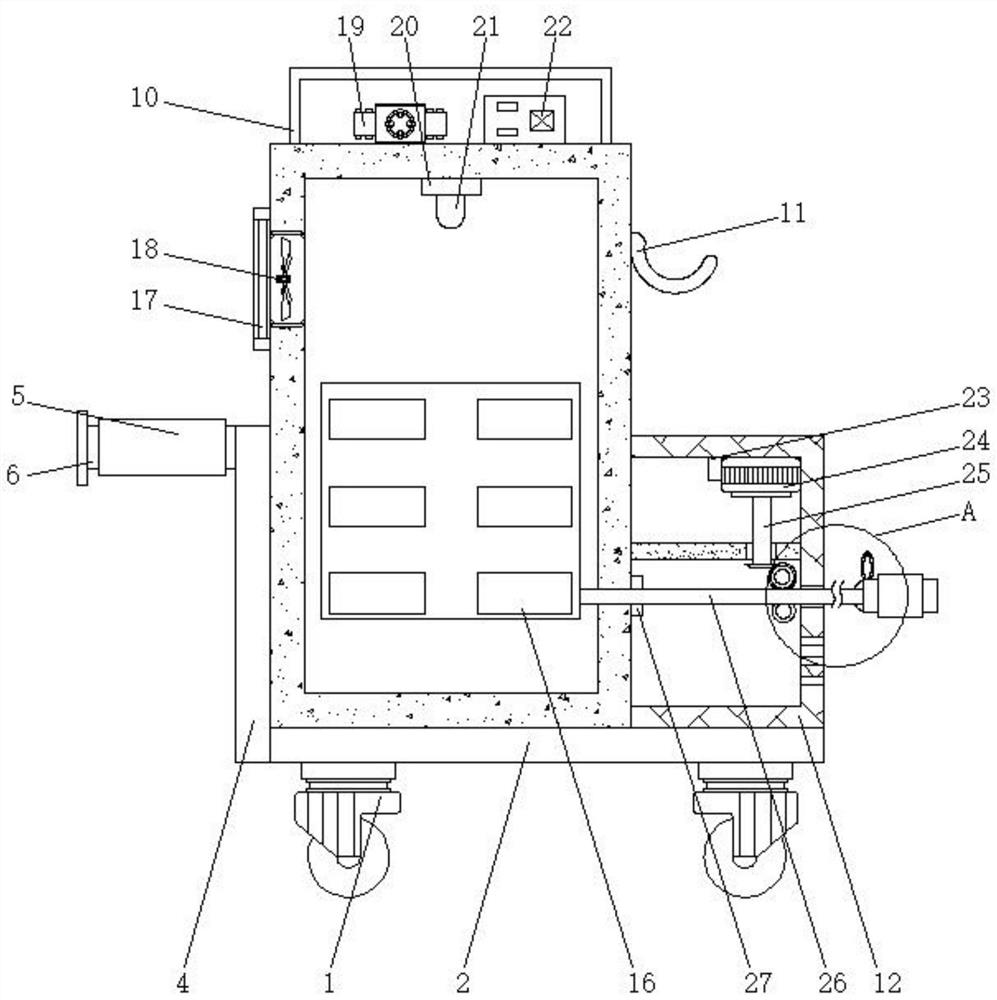

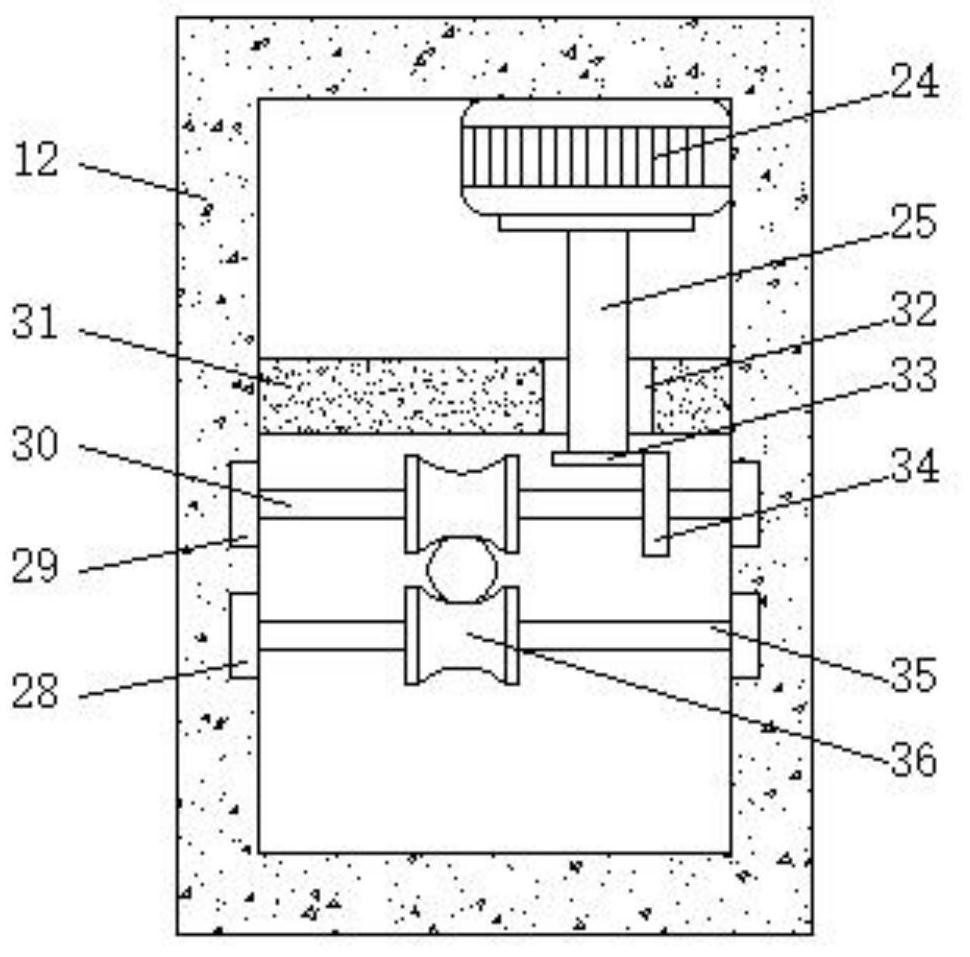

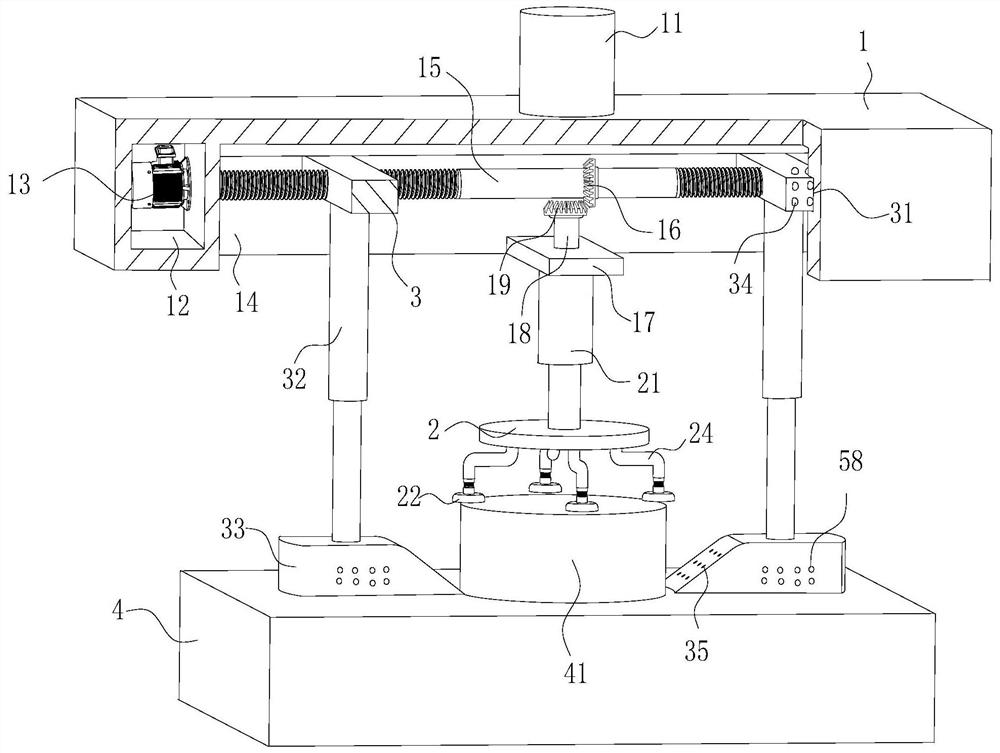

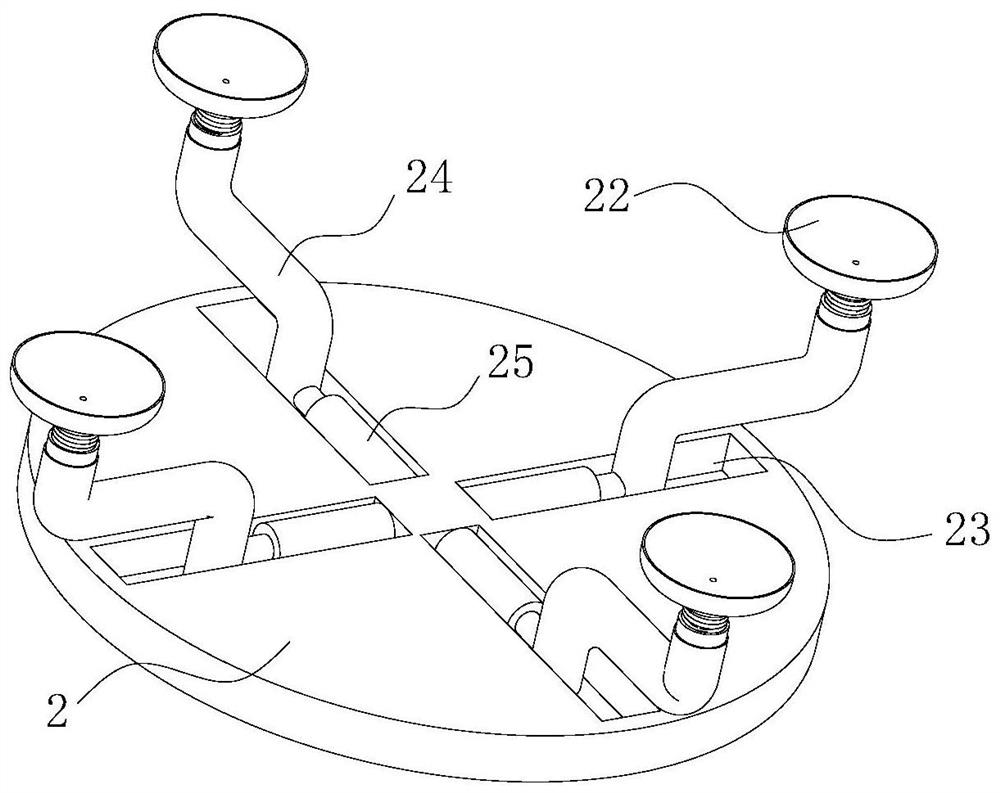

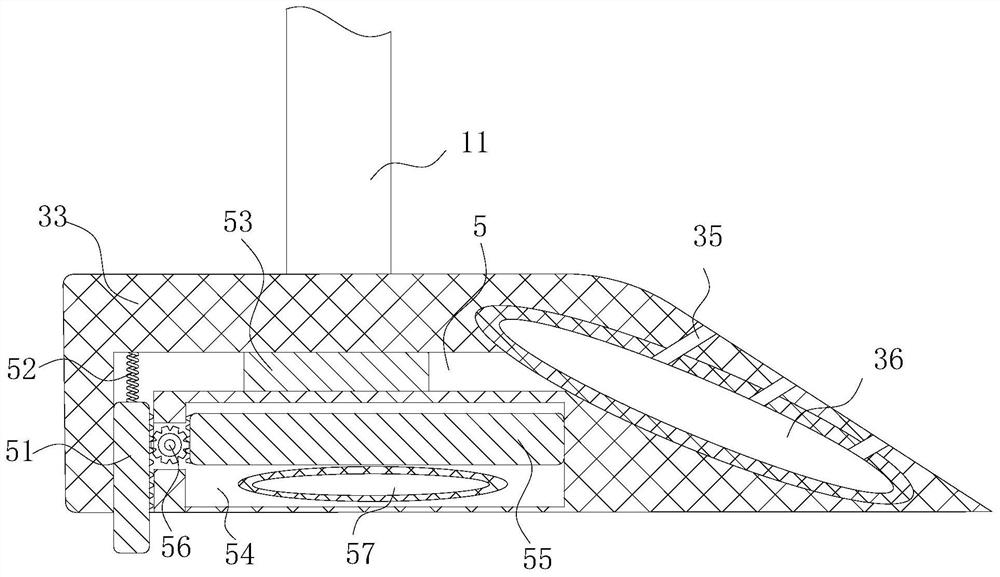

Metal pipe laser cutting machine with chip removing function and chip removing method thereof

InactiveCN109500501AAvoid working hoursImprove work efficiencyLaser beam welding apparatusMetal machiningEngineering

The invention provides a metal pipe laser cutting machine with a chip removing function and a chip removing method thereof, and belongs to the field of metal machining. According to the metal pipe laser cutting machine, the chip removing is achieved by arranging of a chip removing positioning device, specifically a plugging pipe extending into the metal pipe is arranged in the chip removing positioning device, and the purpose of chip removing is achieved by using the plugging pipe to plug during cutting. A chip removing cutting process comprises the following steps of 1, carrying feeding and positioning, feeding the metal pipe to a desired length position; 2, carrying plugging, inserting the plugging pipe into the metal pipe until reaching the cutting position to plug the cutting position,and making the inner space of the metal pipe to be cut is closed; and 3, carrying piy cutting, starting on the laser cutting machine while rotating the metal pipe, and cutting the metal pipe cut under the action of the laser.

Owner:FOSHAN LONGXIN LASER TECH CO LTD

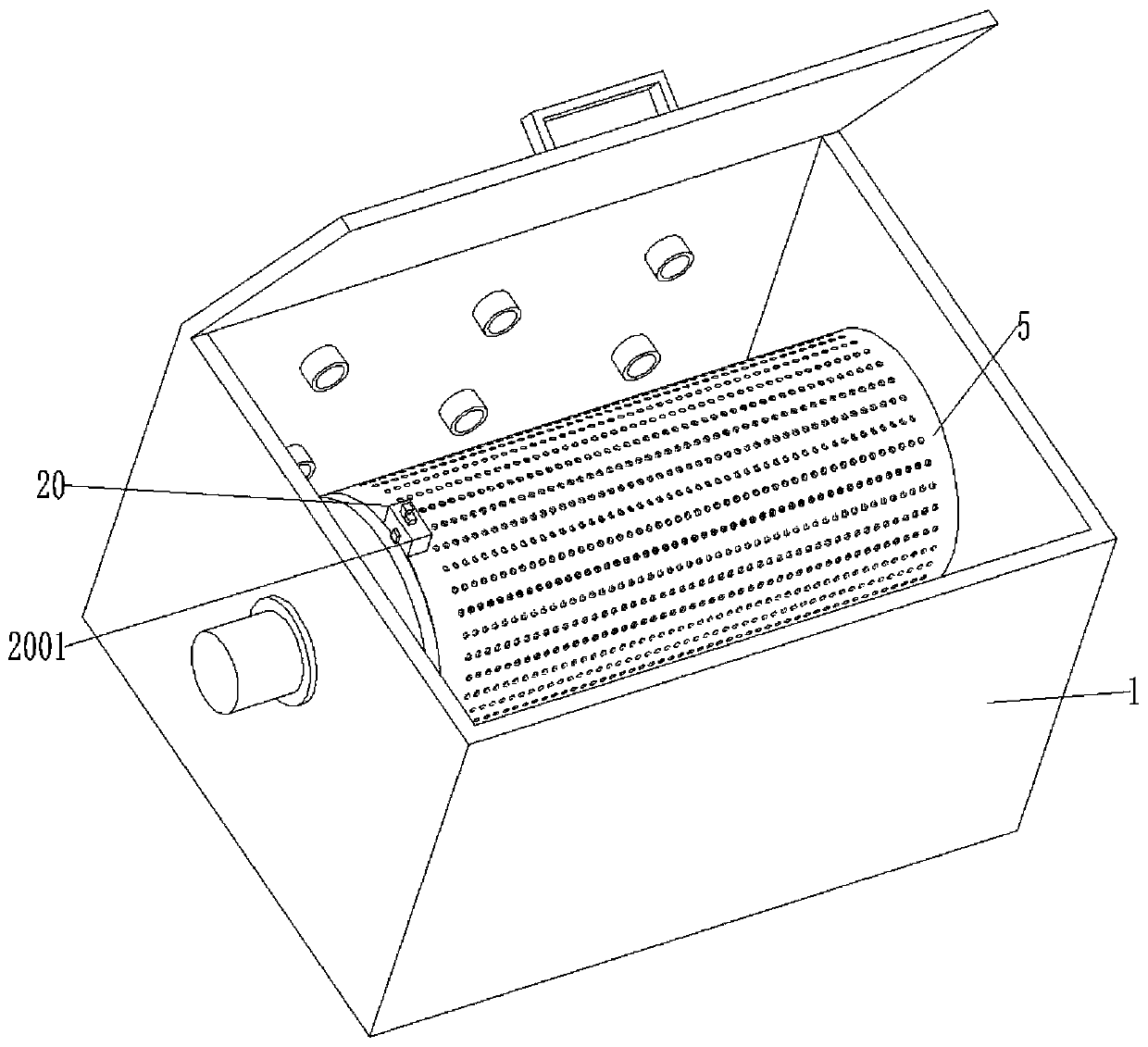

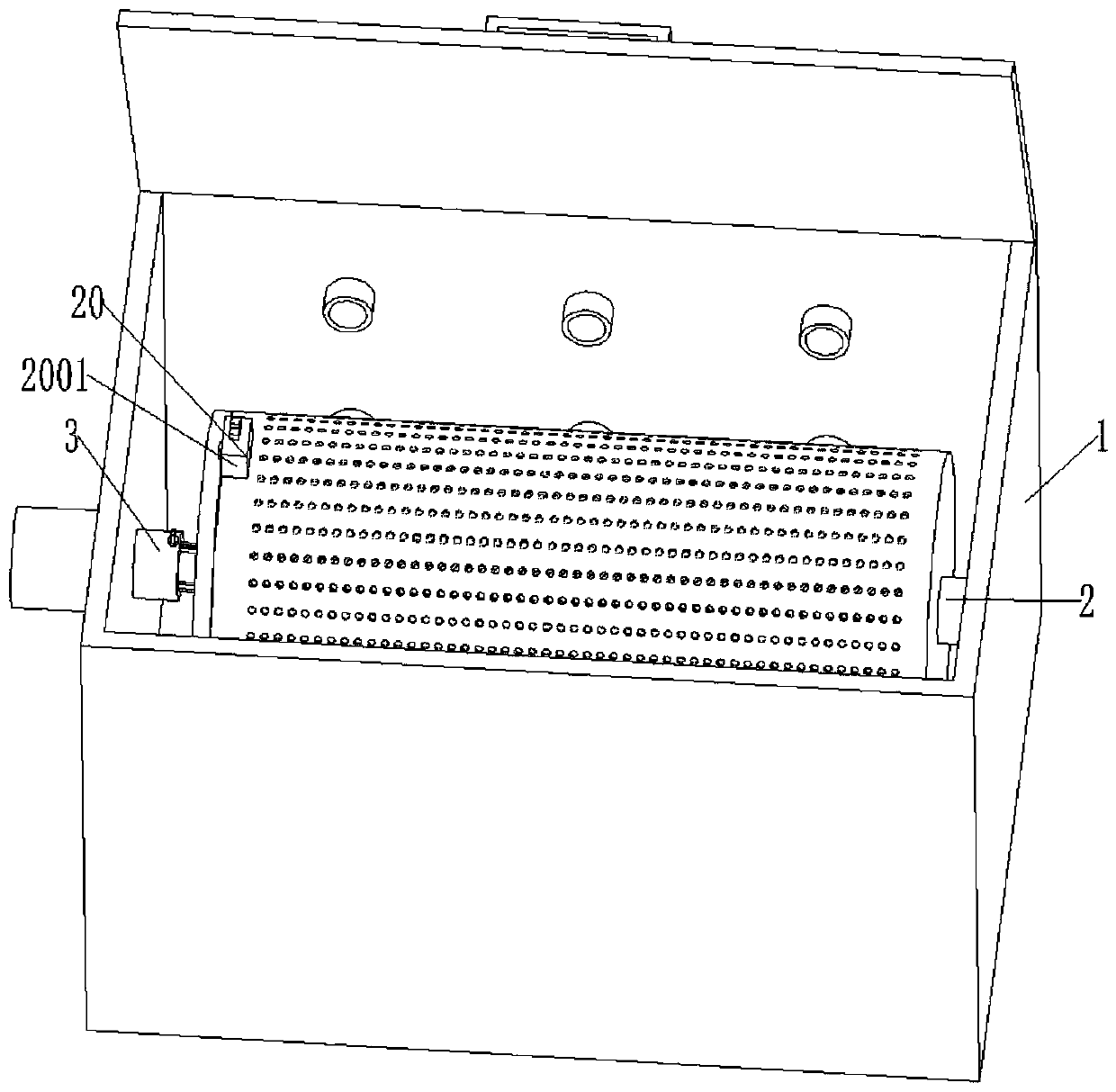

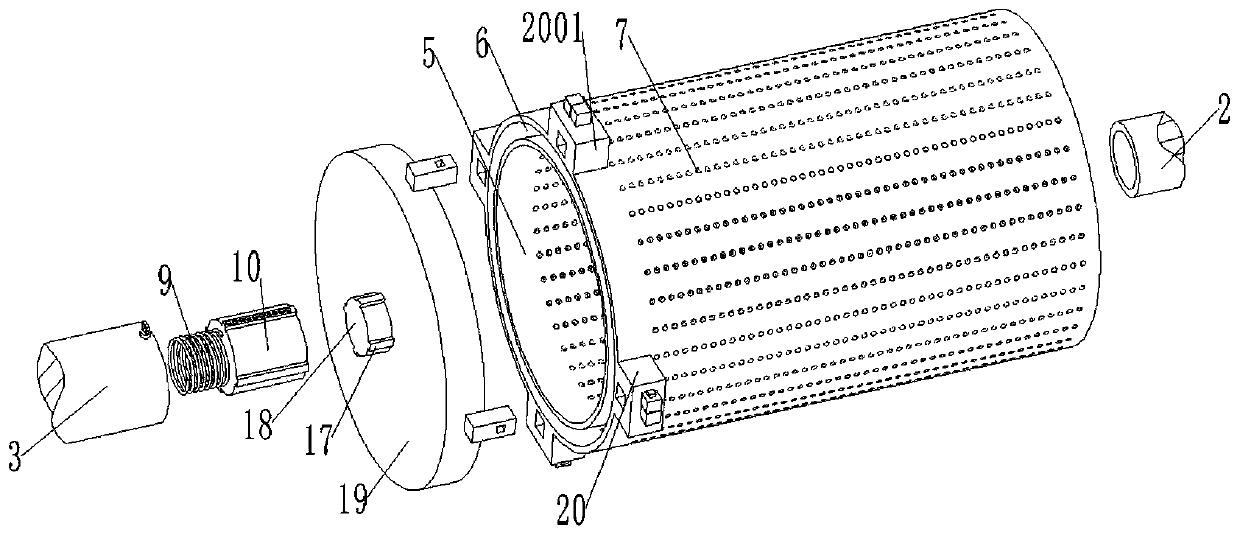

Energy-saving soft capsule rapid drying equipment

ActiveCN111336787AFully dryDry evenlyDrying gas arrangementsDrying chambers/containersEconomic benefitsStructural engineering

The invention discloses energy-saving soft capsule rapid drying equipment. The energy-saving soft capsule rapid drying equipment comprises a main body, a cylinder is integrally connected to one end inthe main body, a first rotating shaft is arranged at the other end of the main body in a penetrated mode, and blowing pipes are integrally arranged in the main body at equidistances. A first groove is formed in the cylinder, a second rotating shaft is inserted in the first groove, and the second rotating shaft is integrally arranged at one end of a holding cylinder. A holding groove is formed inthe holding cylinder, and micro holes are formed in the holding cylinder at equidistances in a penetrated mode. Through the holding cylinder, the holding groove, the first rotating shaft, the second rotating shaft and a third rotating shaft, the energy-saving soft capsule rapid drying equipment can rotate to dry, then drying is more full and uniform, the working efficiency of drying is improved, and the working economic benefit is improved; and taking and placing are very simple and convenient through the holding cylinder, a sealing cover and a fixed device, then the working time is shortened,the working economic benefit is improved, and convenience is brought to the work.

Owner:JIANGSU CHANGHE CAPSULE

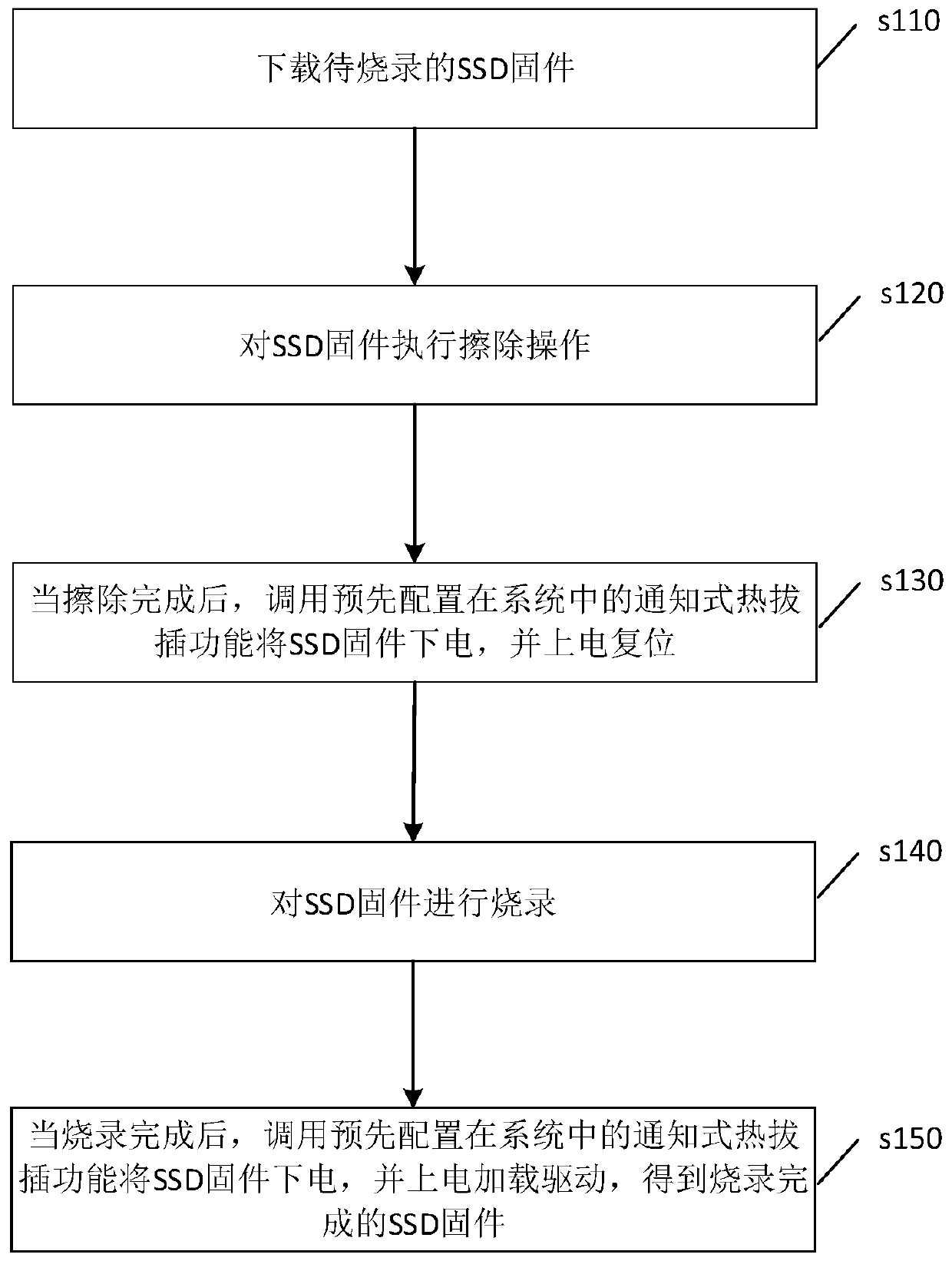

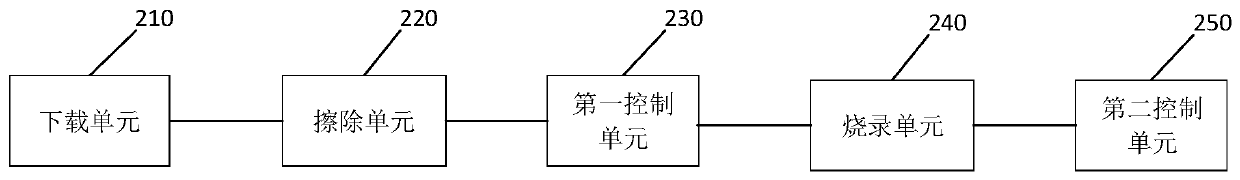

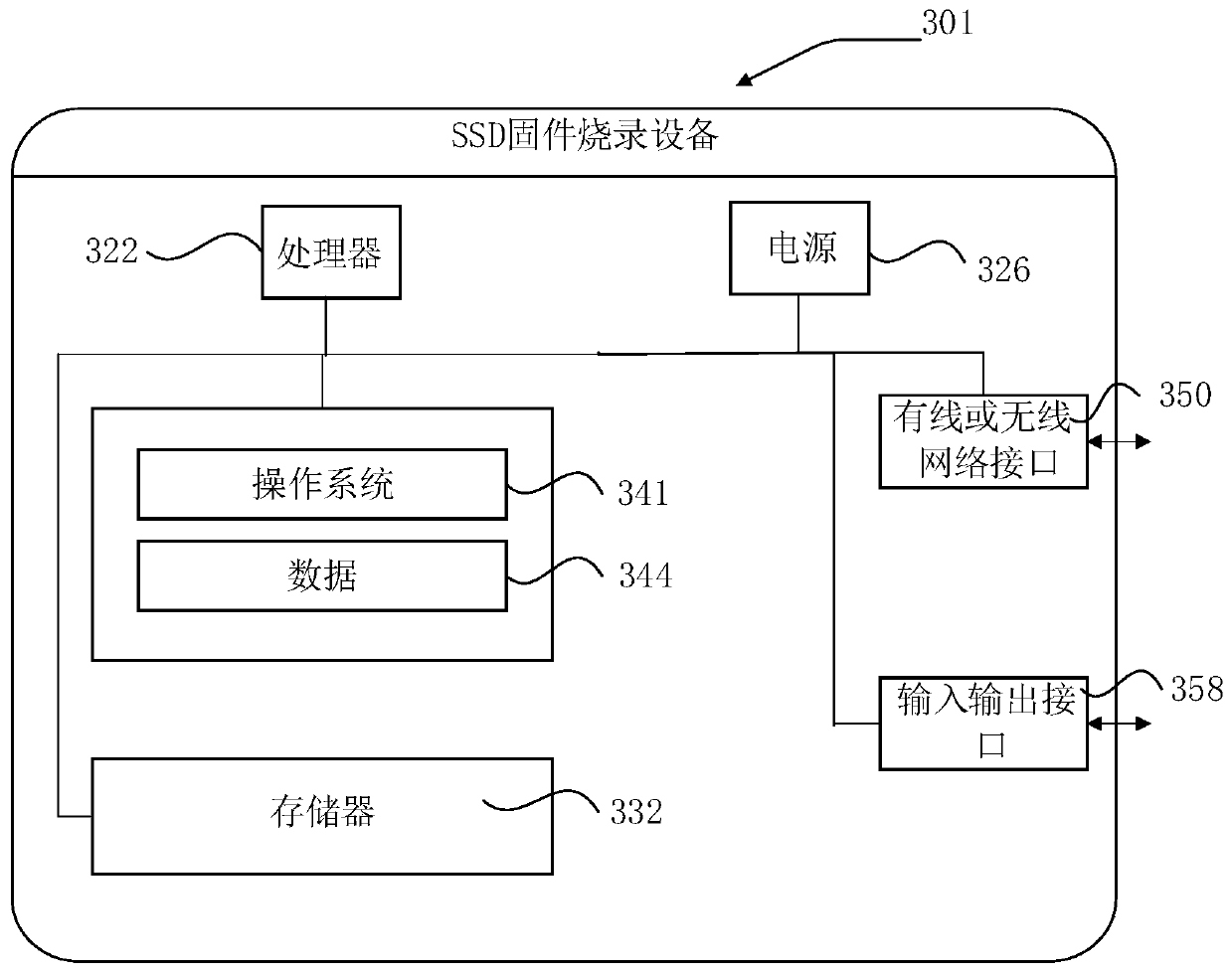

SSD firmware burning method and related components

PendingCN111552486AReduce manual unplugging actionAvoid workloadSoftware deploymentSoftware engineeringWorkload

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

High-efficiency cement stirring device

ActiveCN107718278AWon't leaveIncrease reaction rateShaking/oscillating/vibrating mixersTransportation and packagingHydraulic cylinderDrive wheel

The invention discloses a high-efficiency cement stirring device. The high-efficiency cement stirring device comprises a base, a stand column, longitudinal slide rails, a lifting sliding sleeve, connection pieces, a stirring motor, a main shaft box, a drive wheel, a driving belt, a driven wheel, a main shaft, a stirring blade, a cylinder, a movable shaft, a lifting connector, a hydraulic cylinder,positioning sleeves, limiting springs, supporting bases, a cylinder cover, a drive motor, a transmission wheel, an eccentric wheel, a belt and a positioning piece. When the high-efficiency cement stirring device is used for conducting stirring processing on cement, the cylinder is vibrated and shaken, the reaction rate of materials in the cylinder is accelerated, stirring processing is more thorough, while the reaction rate is accelerated, the phenomenon that the materials adhere to the inner wall of the inner wall of the stirring cylinder is effectively avoided, and therefore the internal capacity of the cylinder is kept, the unnecessary waste of the raw materials is avoided, the working time is effectively shortened, the working efficiency is improved, relatively-high practicality is improved, the operation effect is guaranteed, the high-efficiency cement stirring device adapts to multiple different working modes, and the labor using is effectively reduced.

Owner:平阴山水水泥有限公司

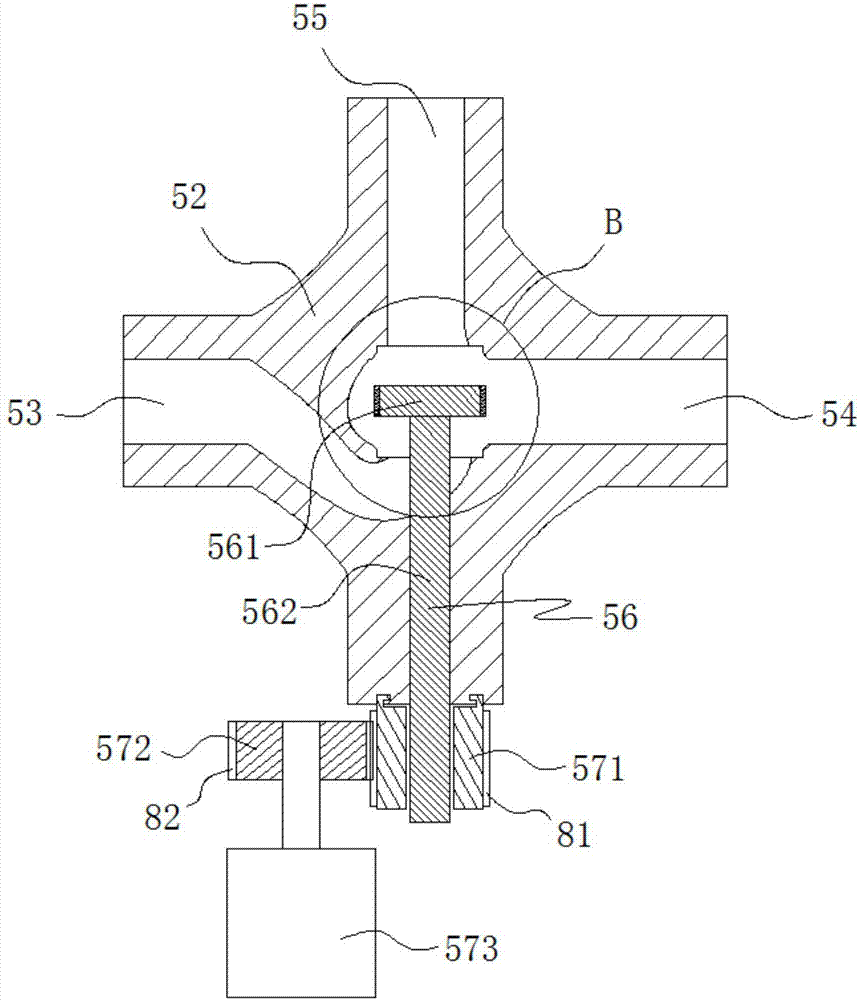

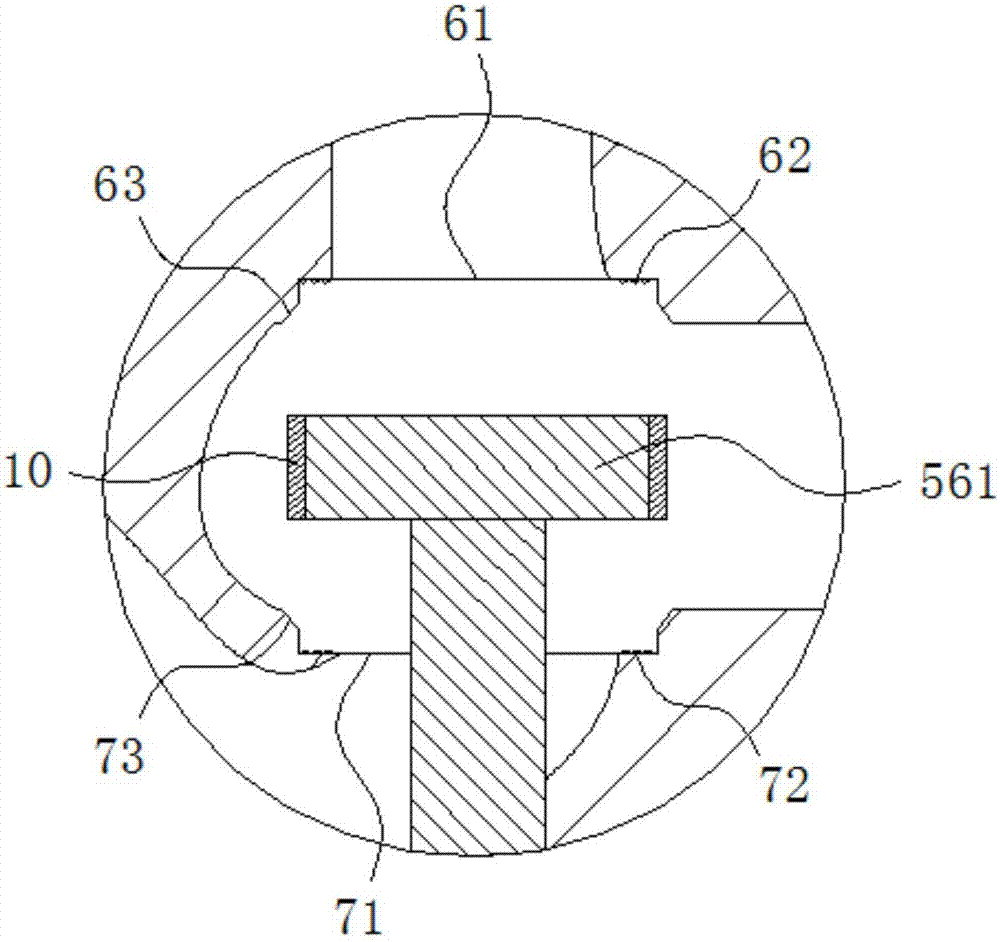

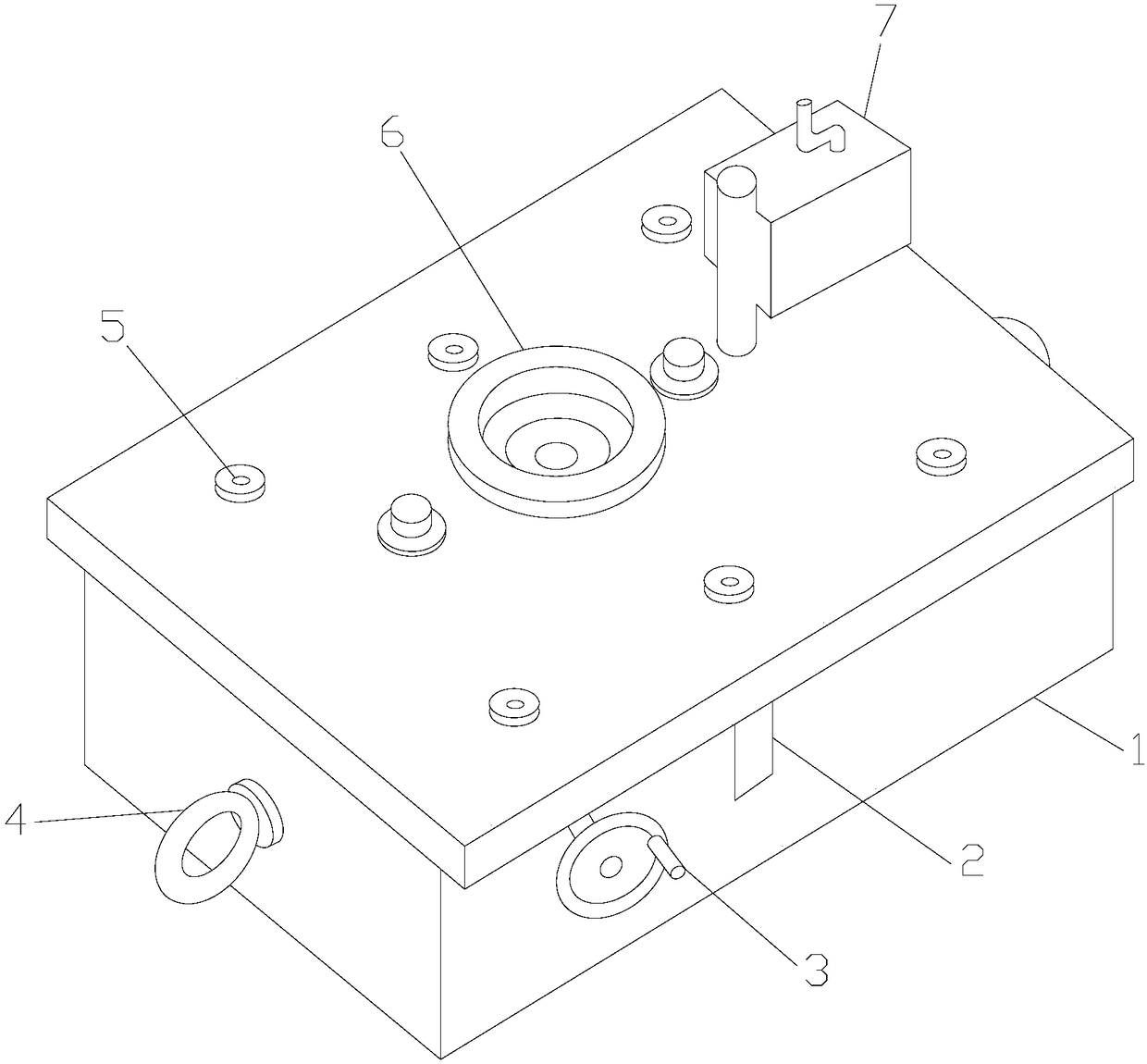

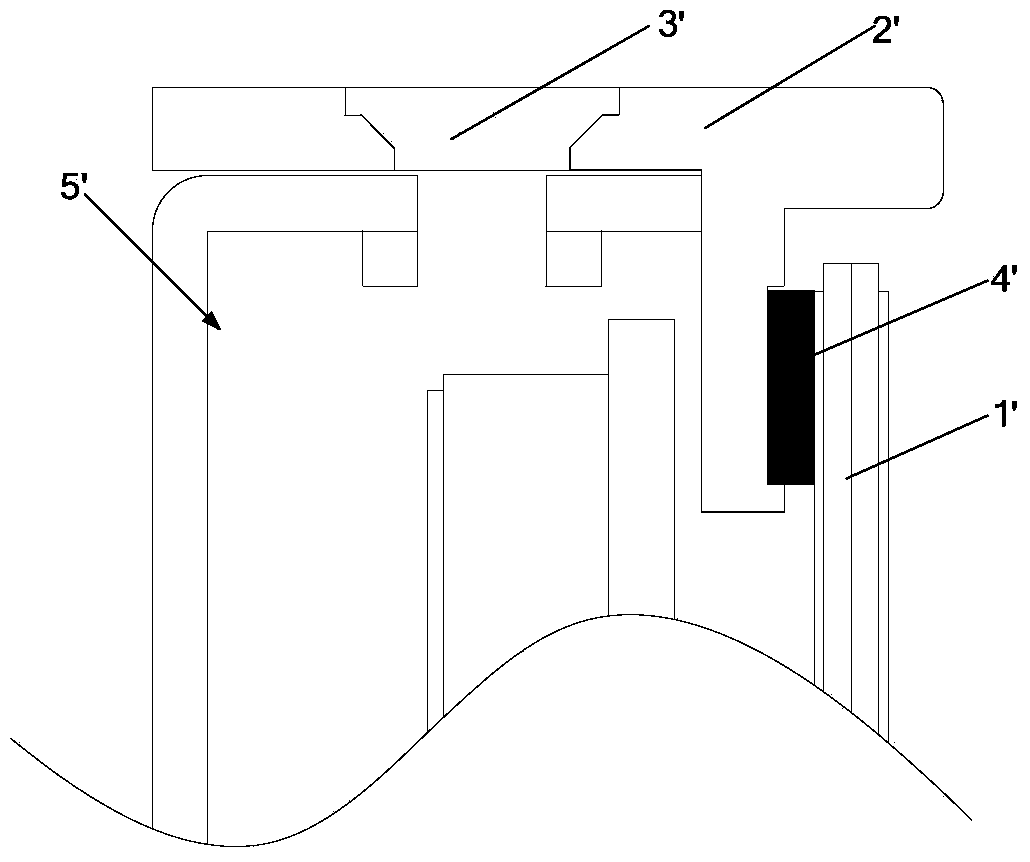

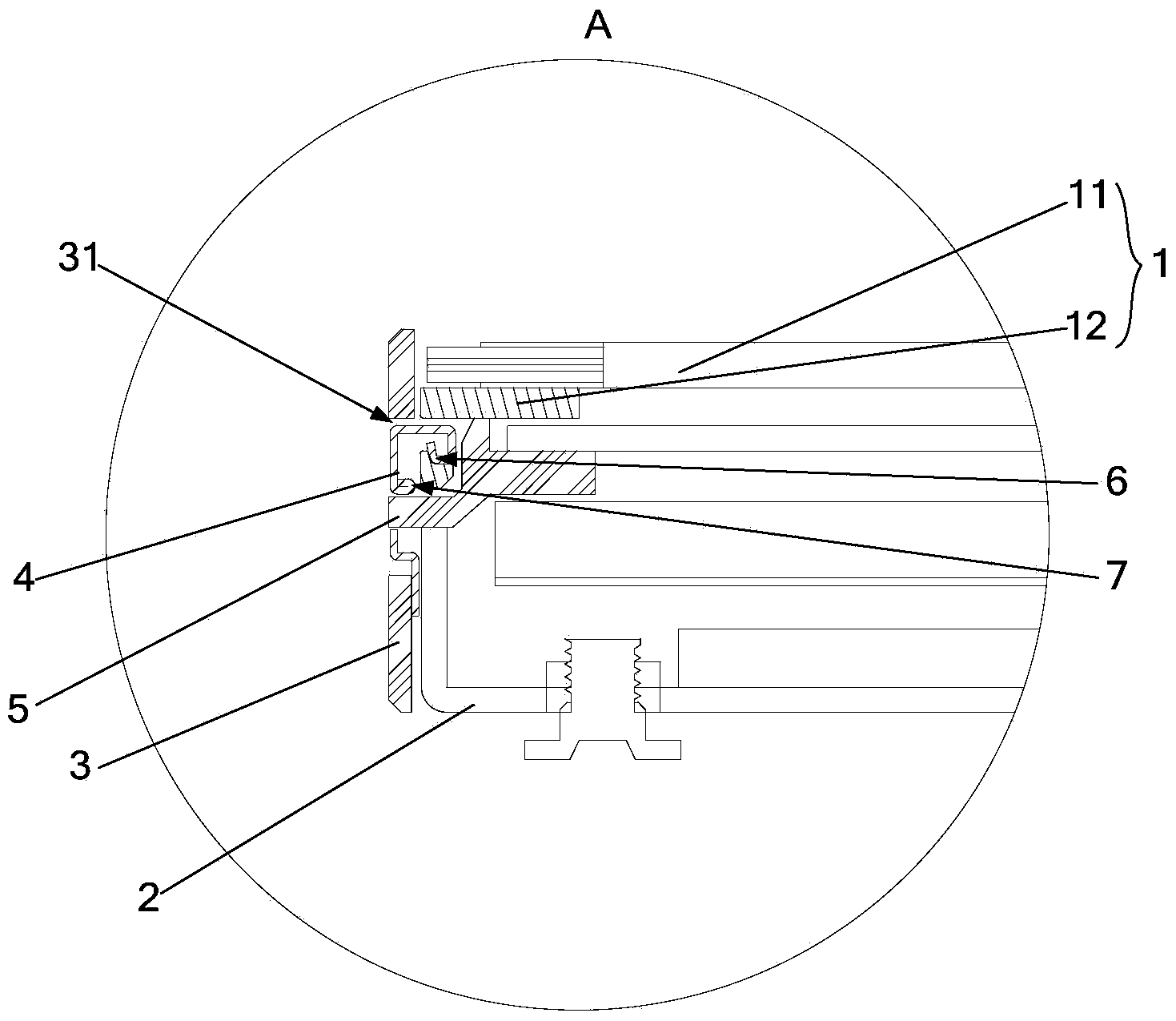

Hydraulic pressure test sealing tool and hydraulic pressure test method for pipelines

PendingCN107101893ASimple structureEasy to manufactureMaterial strength using tensile/compressive forcesEngineeringFlange

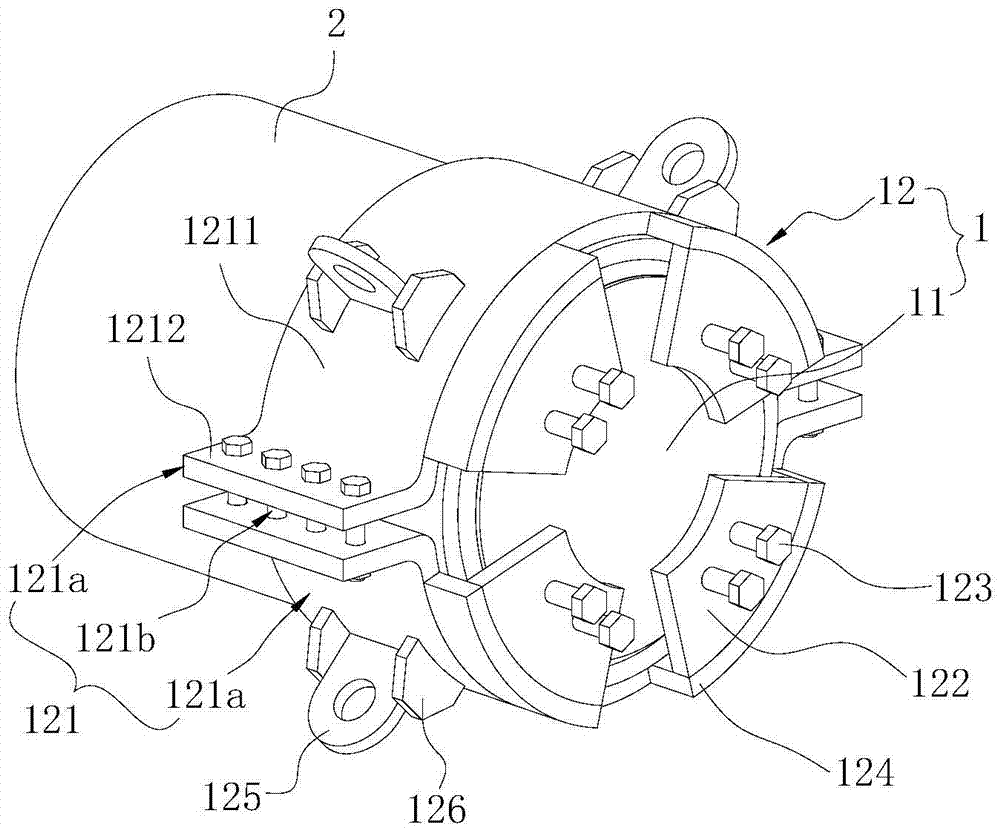

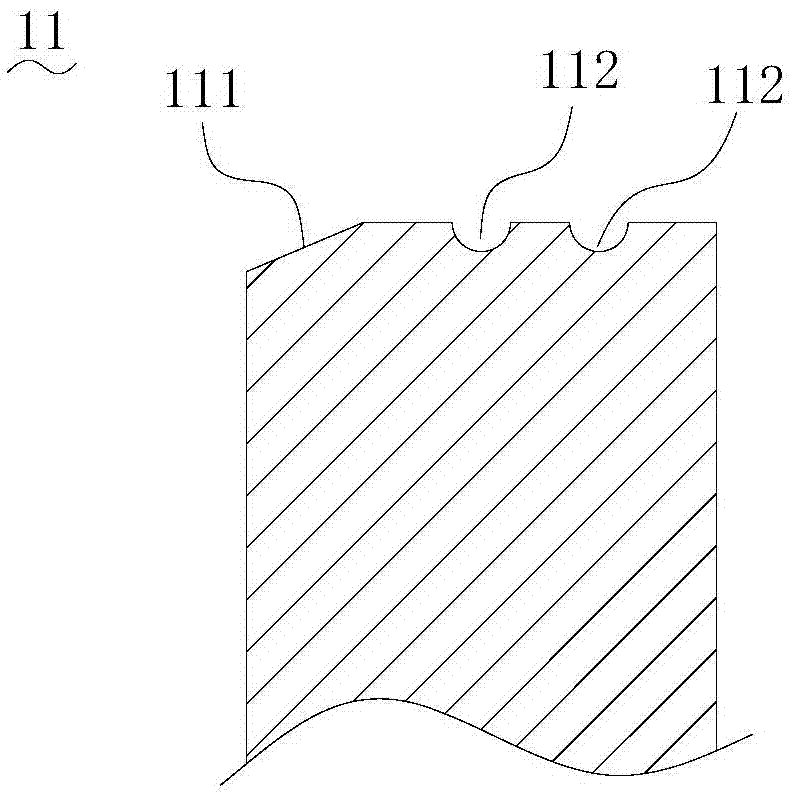

The present invention provides a hydraulic pressure test sealing tool and a hydraulic pressure test method for pipelines. The hydraulic pressure test sealing tool comprises a sealing plate and a position limiting clamper, wherein the sealing plate is adapted to the inner diameter of a pipeline, and can be filled in the pipe mouth of the pipeline, the position limiting clamper comprises a hoop hooped on the outer wall of the pipeline and a position limiting baffle positioned on one end of the hoop and perpendicular to the hoop, and the position limiting baffle extends along the axial line of the hoop so as to stop the sealing plate. According to the present invention, the sealing tool can seal the pipeline when the pipeline is subjected to the hydraulic pressure test, wherein the pipe mouth of the pipeline is filled and sealed with the sealing plate, and the sealing plate is subjected to stopping position limiting by clamping the pipeline on the outer side of the pipeline through the position limiting clamper, such that the pipeline sealing can be achieved without the flange structure, and the waste of the material, the working time and the labor due to the pipe section extending can be avoided; and the sealing tool has characteristics of simple structure, convenient production, convenient operation, recycling more times, and wide application range.

Owner:南通中集太平洋海洋工程有限公司 +2

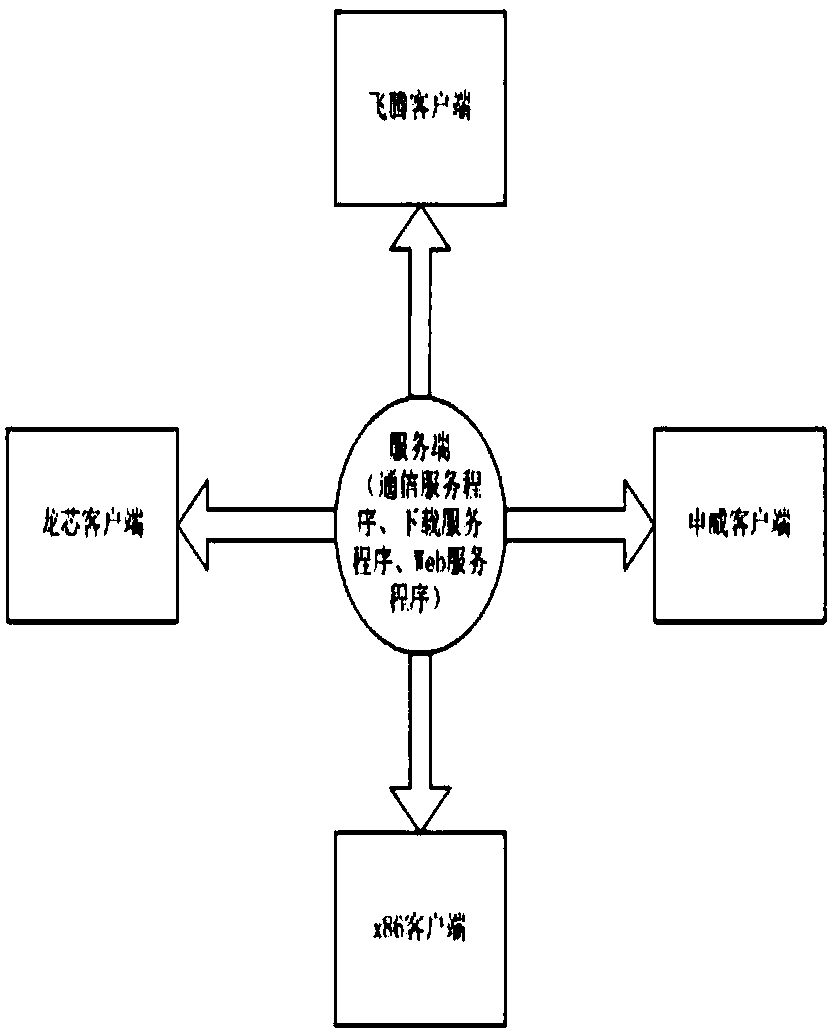

Automatic software updating and pushing method based on domestic CPU and operating system

InactiveCN108173890ALimit quantityReduce loadTransmissionSoftware deploymentFailure rateOperational system

The invention discloses an automatic software updating and pushing method based on a domestic CPU and operating system, belongs to a software updating method of a domestic client side hardware platform, and solves the problems of high failure rate, many problems, frequent updating and no mature automatic updating tool in a domestic hardware platform environment. The technical scheme is as follows:a system structure including a client side and a server side is adopted; the server side is used for publishing an updating strategy and a software updating packet; the client side is used for downloading and updating the software updating packet; the server side integrates a communication service program, a downloading service program, a web service program and a software updating strategy file;the client side integrates a communication service program and a downloading service program; the communication service program of the client side is used for communicating with the server side to obtain information of the software updating packet needing to be updated; furthermore, the software updating packet needing to be updated and the software updating strategy file are downloaded through the downloading service program of the client side; and, after downloading is completed, the client side performs updating installation of the software updating packet.

Owner:JIANGSU HANNO INFORMATION & TECH CO LTD

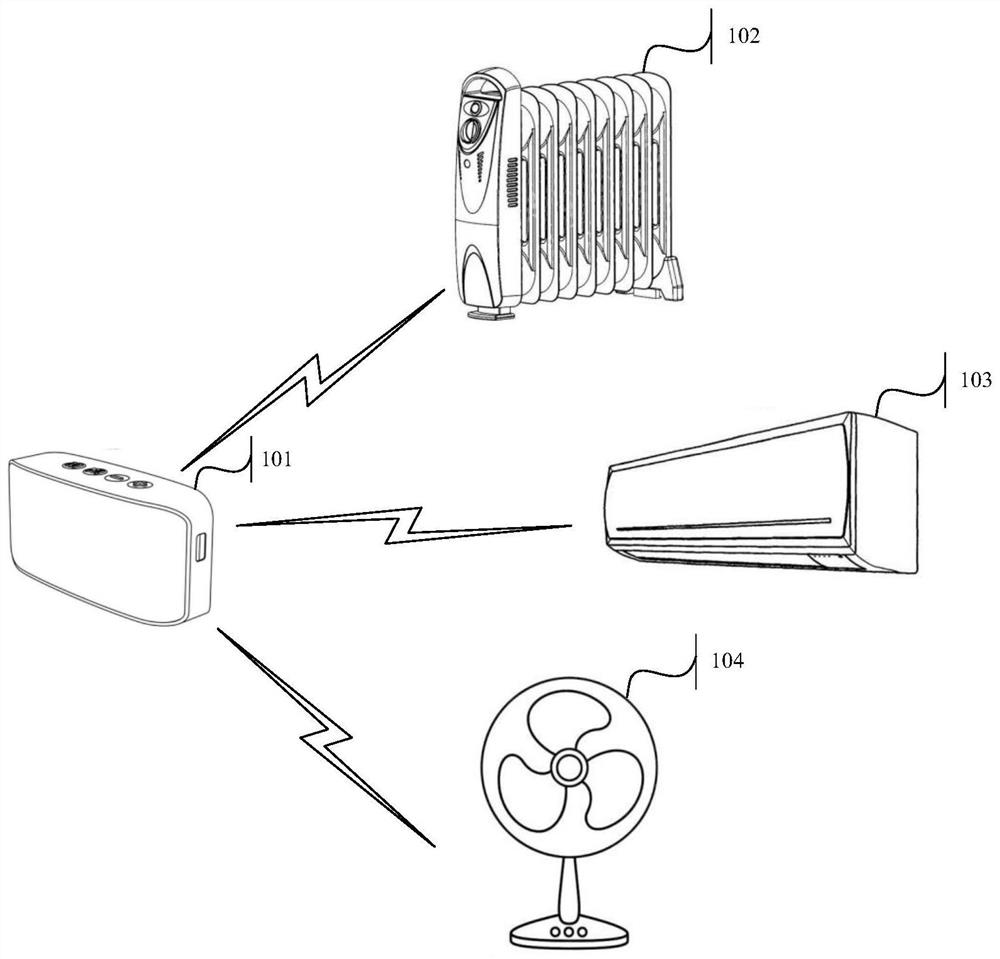

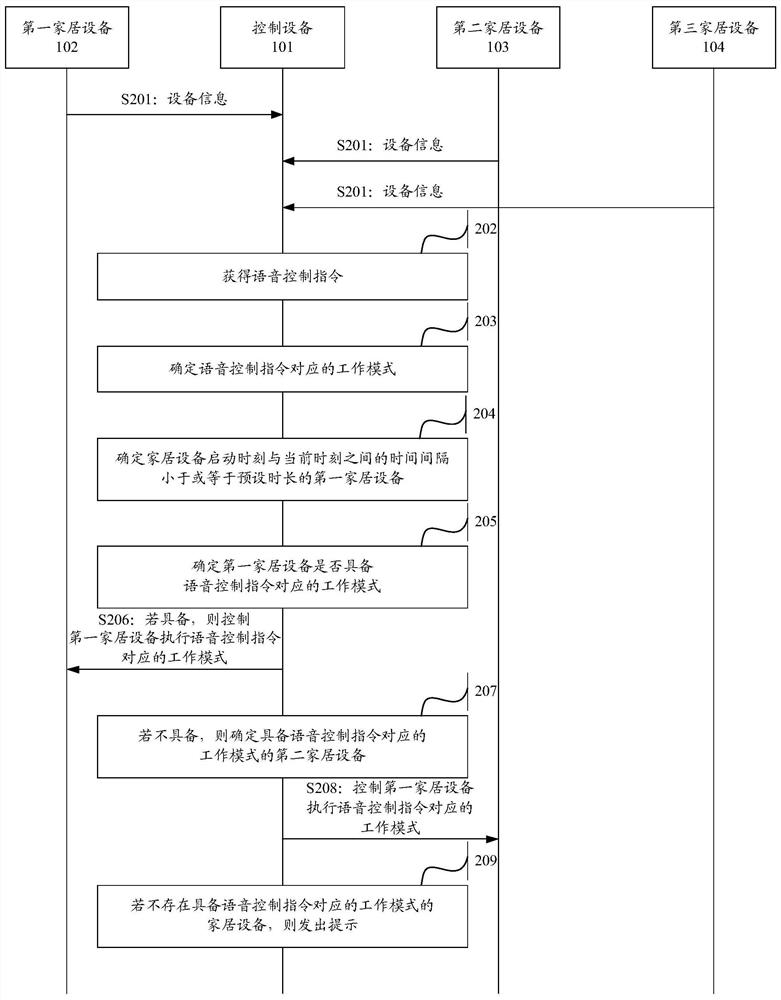

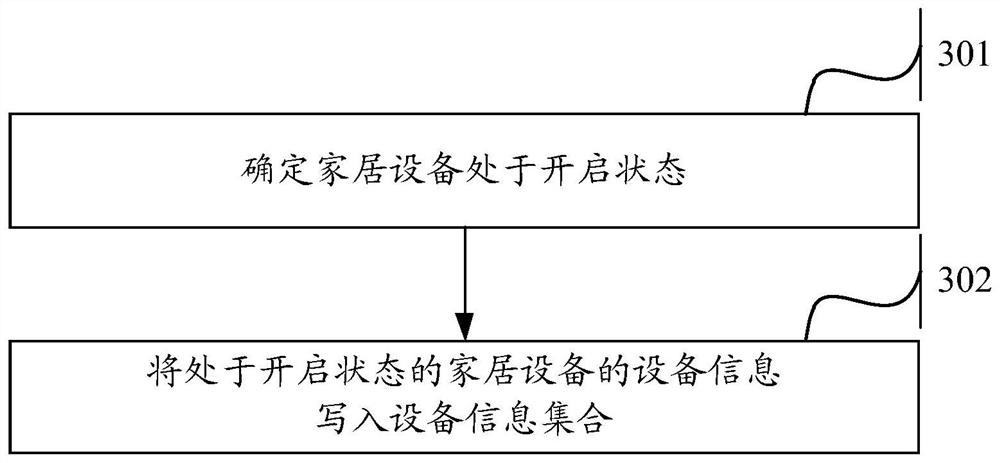

Method and device for controlling household equipment, computer equipment and storage medium

PendingCN111654420AAvoid working hoursAvoid loadSpeech recognitionHome automation networksControl engineeringSpeech sound

The invention relates to the technical field of computers, and provides a method and a device for controlling household equipment, computer equipment and a storage medium, which are used for improvingthe efficiency of controlling the household equipment. The method comprises the steps of obtaining a voice control instruction, wherein the voice control instruction is used for indicating to start aworking mode; in an equipment information set, determining first household equipment which is in an on state and has a time interval between a starting moment and a current moment less than or equalto a preset time length, the equipment information set comprising equipment information of at least one household equipment in the on state, and the equipment information comprising an equipment starting moment; determining that the first household equipment has a working mode corresponding to the voice control instruction according to the voice control instruction; and controlling the first household equipment to execute a working mode corresponding to the voice control instruction.

Owner:GREE ELECTRIC APPLIANCES INC +1

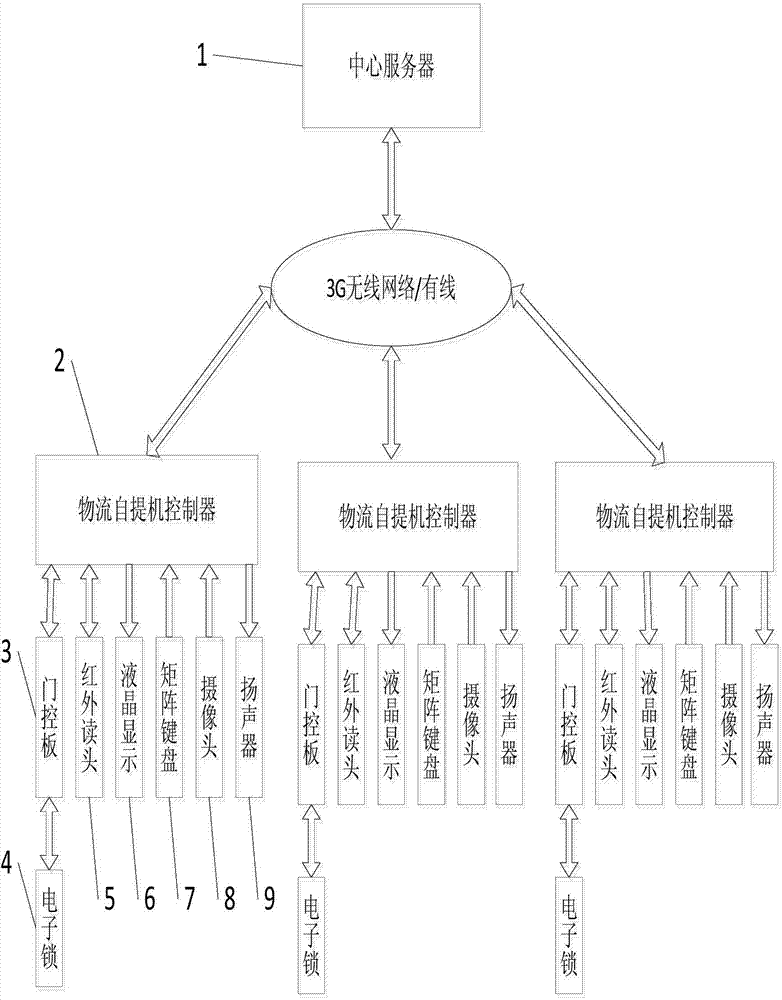

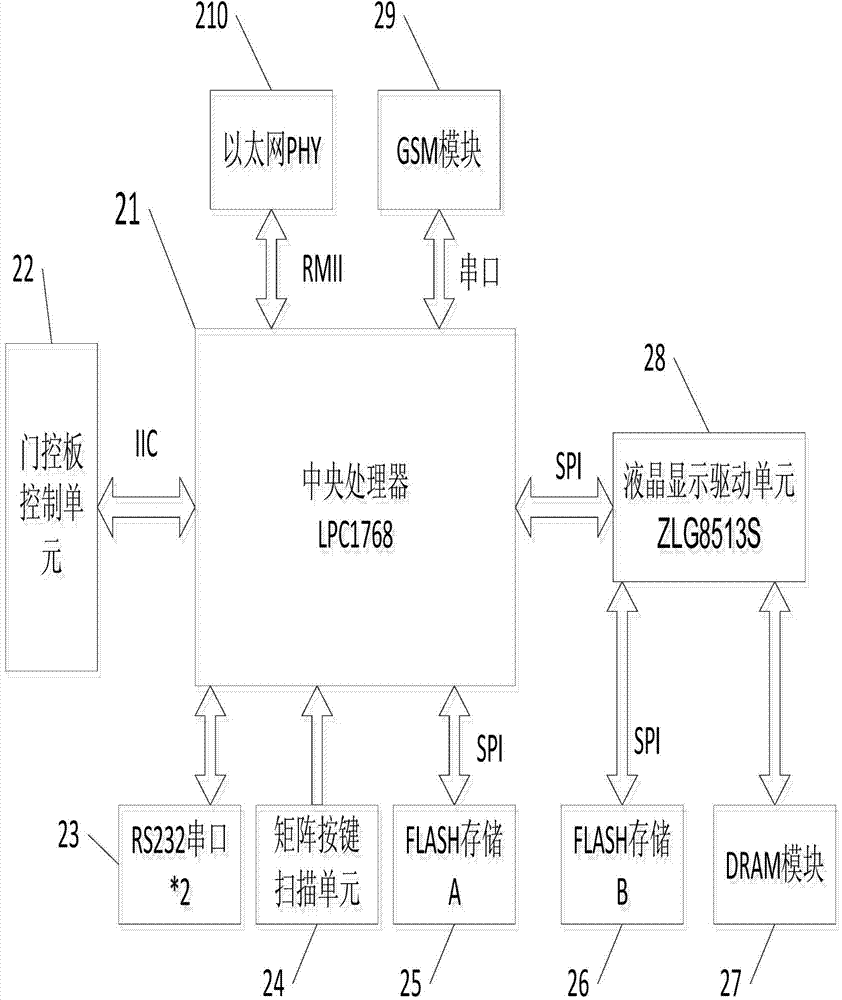

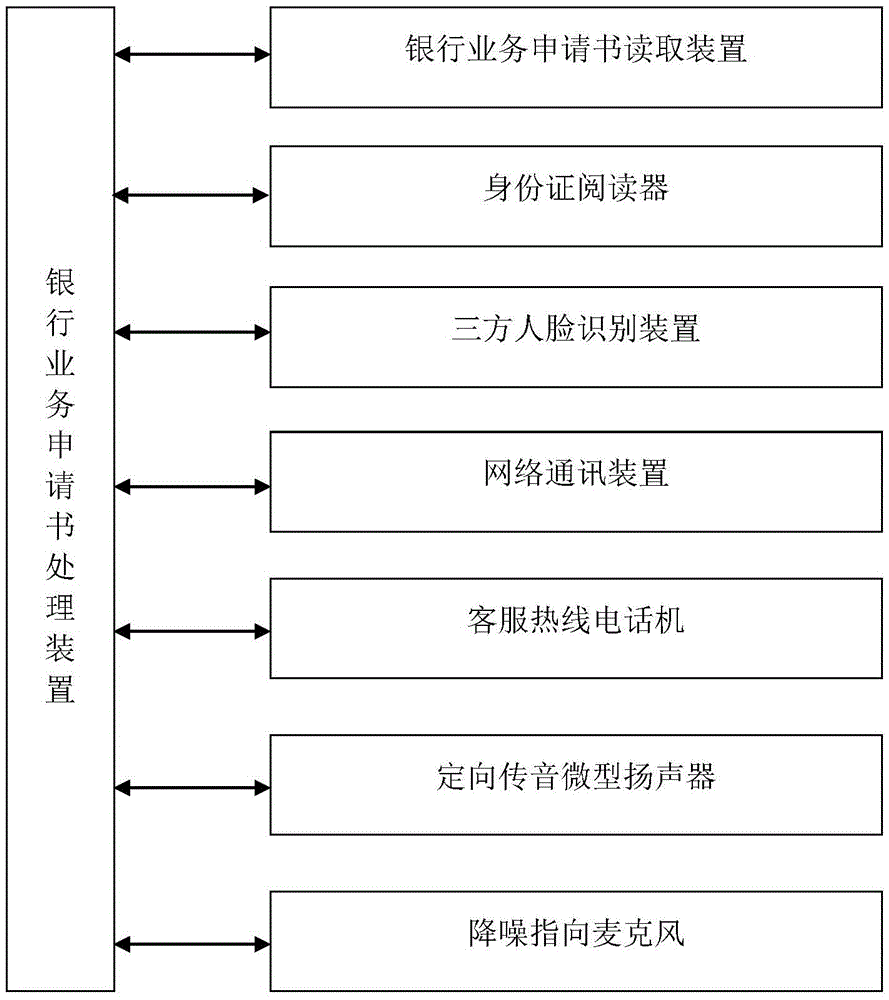

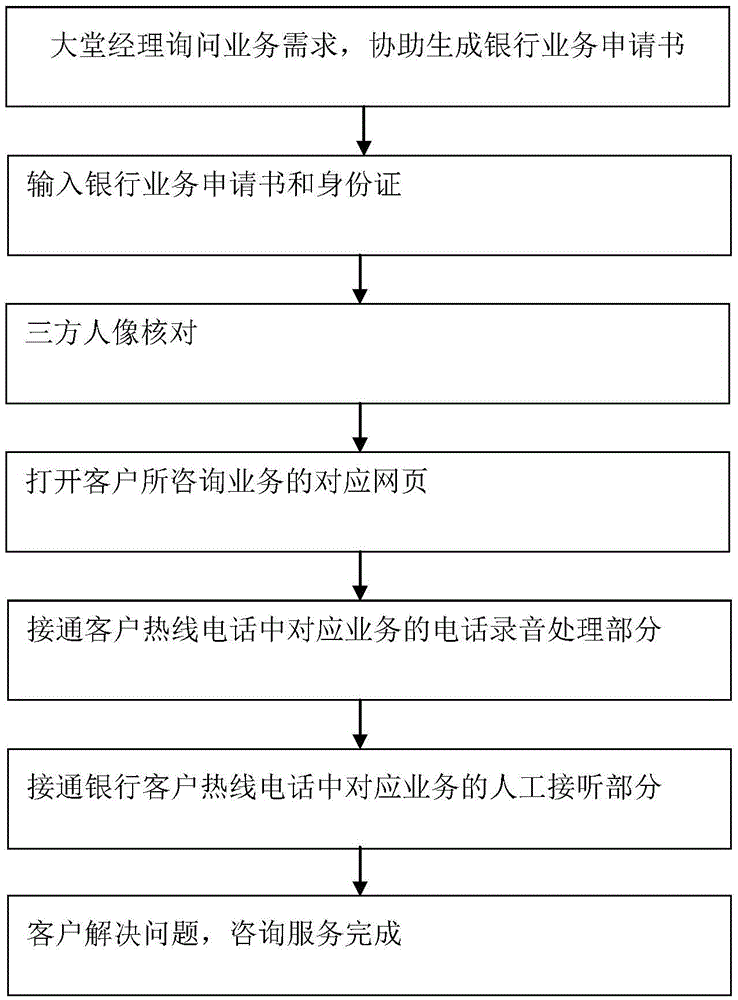

Intelligent terminal service system for people's convenience

InactiveCN104504766AEasy to operateImprove work efficiencyFranking apparatusLogisticsKey pressingNetwork connection

The invention discloses an intelligent terminal service system for people's convenience. The intelligent terminal service system comprises a central server and at least one logistics self-pickup machine controller. The central center is connected with the logistics self-pickup machine controllers through a 3G (the third generation telecommunication) wireless network or a wired network. Each logistics self-pickup machine controller is in communication connection with a door control panel, an infrared read head, a liquid crystal display, a matrix keyboard, a camera and a loudspeaker. Each door control panel is in communication connection with an electronic lock. Each logistics self-pickup machine controller internally comprises a center processing unit, and further comprises a door control panel control unit, a matrix keyboard scanning unit, a liquid crystal display driving unit, a storage and a communication unit which are electrically in communication connection with the central processing unit. The door control panel control units are in communication connection with the door control panels electrically. The liquid crystal display driving units are in communication connection with the matrix keyboard scanning units electrically. The communication units are used for achieving communication network connection between the logistics self-pickup machine controllers and the central server. The intelligent terminal service system has the advantages that burdens of couriers are relieved greatly and flexibility in pickup of receivers is improved greatly.

Owner:SICHUAN JIUZHOU VIDEO TECH

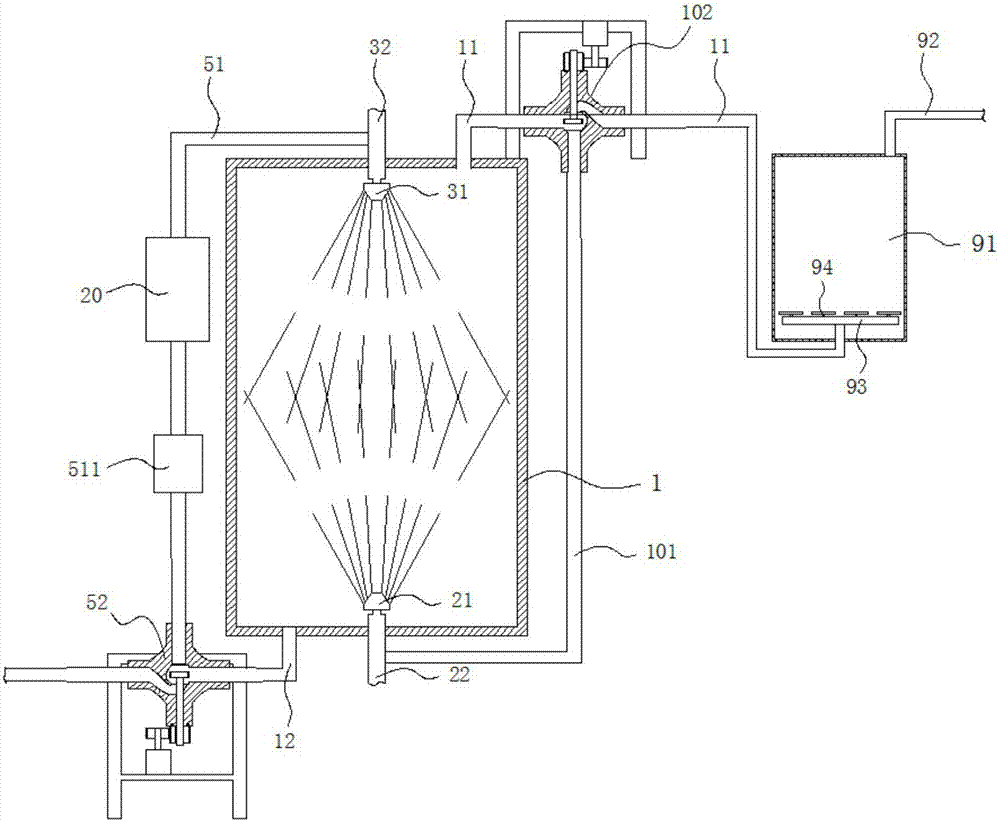

Absorption system for industrial exhaust gas treatment

InactiveCN107469572AAutomate operationEasy to useGas treatmentDispersed particle separationExhaust gasProcess engineering

The invention discloses an absorption system for industrial waste gas treatment, which comprises a tower body, an air injection device, a water injection device, a gas recovery device and a liquid recovery device; the air injection device includes an air injection part arranged at the lower part of the tower body and The air inlet pipe connected with the air spraying part; the water spraying device includes a water spraying part arranged on the upper part of the tower body and a liquid inlet pipe connected with the water spraying part; the upper part of the tower body is provided with an air outlet pipe, so The lower part of the tower body is provided with a liquid outlet pipeline; the liquid recovery device includes a liquid recovery pipeline for connecting the liquid outlet pipeline and the liquid inlet pipeline and a movable adjustment component arranged at the connection between the liquid recovery pipeline and the liquid outlet pipeline. The invention is equipped with a gas recovery device and a liquid recovery device, and the waste gas and liquid can undergo multiple reactions in the same absorption tower, so as to ensure that the hydrogen chloride in the waste gas can be completely absorbed.

Owner:郭玉连

Novel gas recoverable injection mold

The invention discloses a novel gas recoverable injection mold. The injection mold structurally comprises an injection mold body, an observation window, a driving handwheel, a bolt rod, screws, an injection pipe and a gas recovery device. In order to realize gas recovery capacity of the novel gas recoverable injection mold, a first vibration mechanism and a second vibration mechanism are arrangedin the injection mold, the first vibration mechanism is driven by the driving handwheel to drive the second vibration mechanism through a belt to vibrate a mold forming frame, so that harmful gas in an injection material enters a degassing pipe, harmful gas in the degassing pipe is extracted and collected by the gas recovery device, air pollution is avoided, the qualified rate of plastic parts isincreased, the rework rate is reduced, waste of working hours and production cost is avoided, and the production efficiency is increased.

Owner:惠安耐亚节能科技有限公司

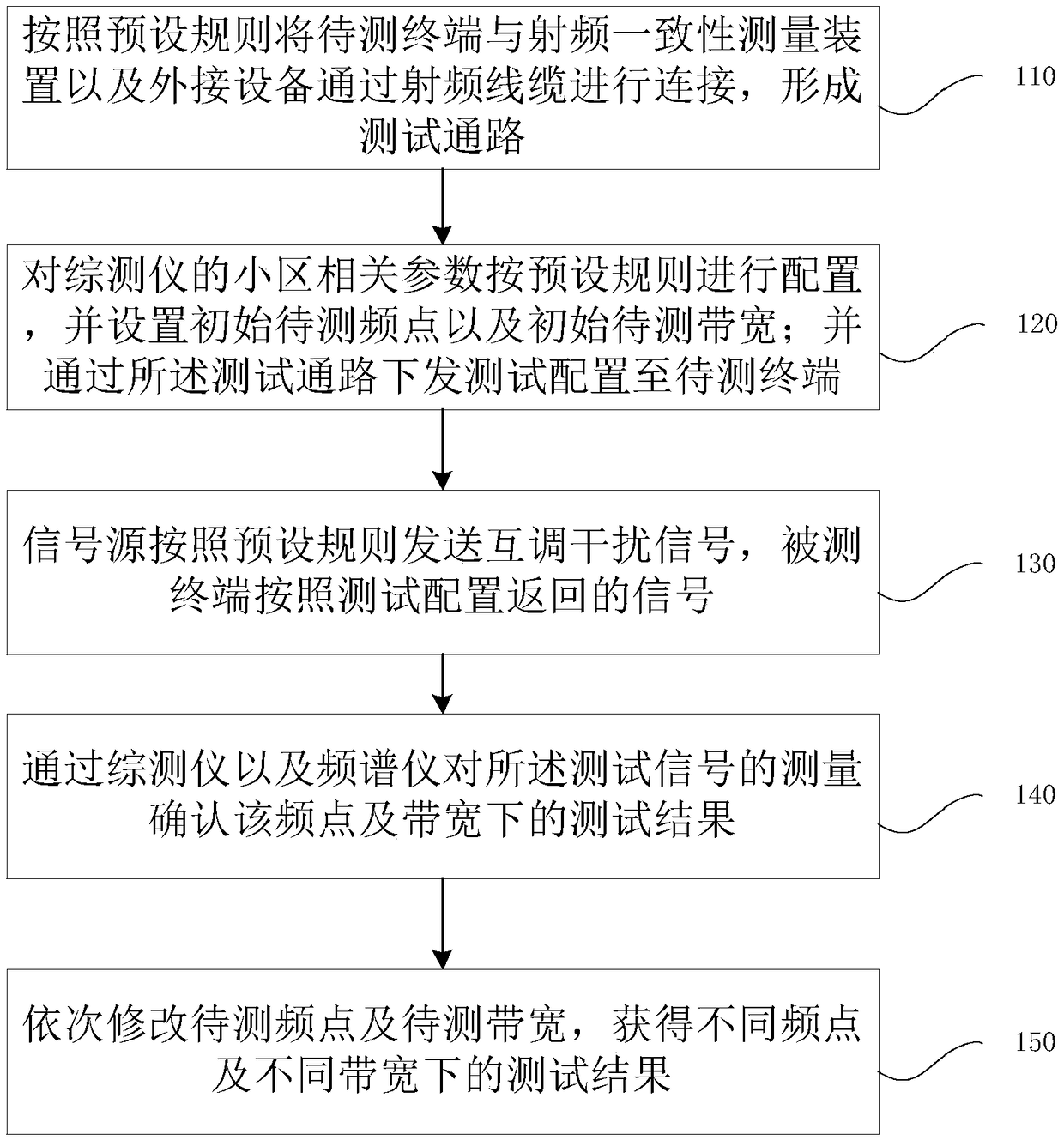

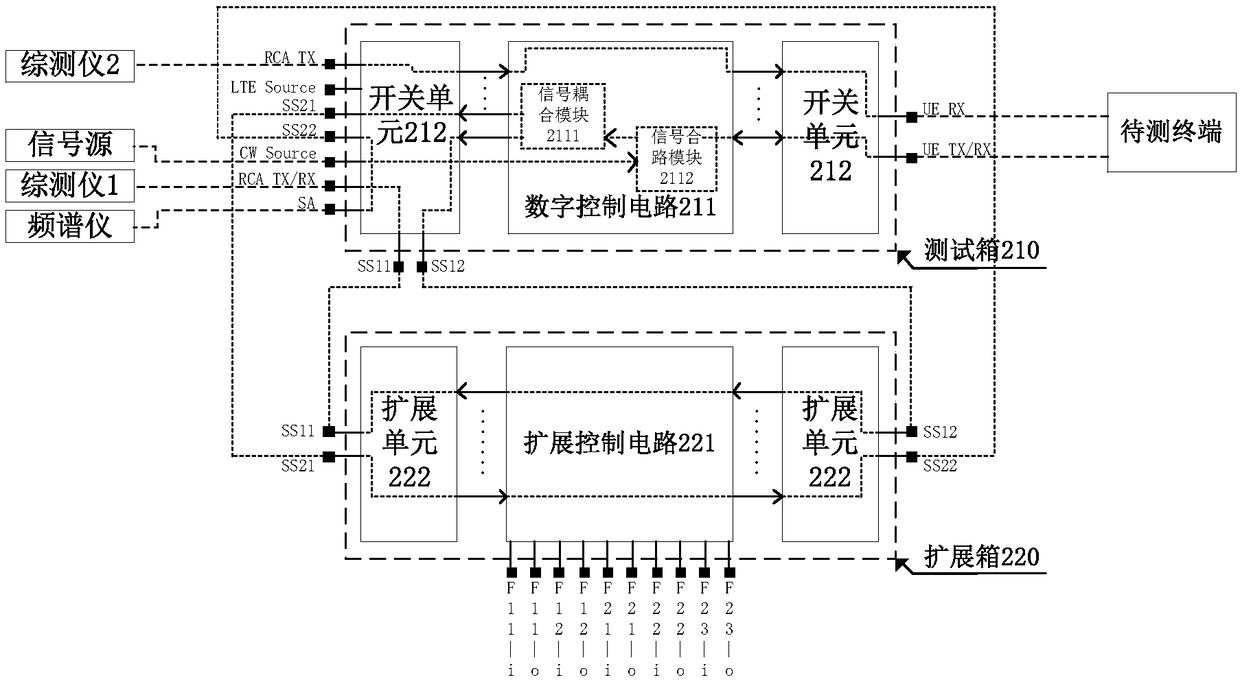

1800M radio frequency consistency emission intermodulation test method and device

InactiveCN108833029AAvoid manpower and man-hoursImprove efficiencyTransmitters monitoringLine-transmission monitoring/testingRadio frequencyMeasurement device

The invention discloses a 1800M radio frequency consistency emission intermodulation test method and device. The method comprises the following steps: connecting a terminal to be tested with a radio frequency consistency measuring device and external equipment through a radio frequency cable according to a preset rule to form a test channel; configuring cell relevant parameters of a comprehensivemeasuring instrument according to the preset rule, and setting initial frequency points and initial bandwidths; issuing a test configuration to the terminal to be tested through the test channel; sending an intermodulation interference signal by a signal source according to the preset rule, and returning the signal by a terminal under test according to the test configuration; combining the intermodulation interference signal with the signal returned by the terminal under test to form a test signal; confirming a test result under the frequency points and the bandwidths through the measurement of the test signal by the comprehensive measuring instrument and a frequency spectrograph; and sequentially modifying the frequency points to be tested and the bandwidths to be detected, so as to obtain the test results under different frequency points and different bandwidths. The method and the device provided by the invention improve the efficiency and also improve the accuracy and reliability of the emission intermodulation test.

Owner:CHINA ELECTRIC POWER RES INST

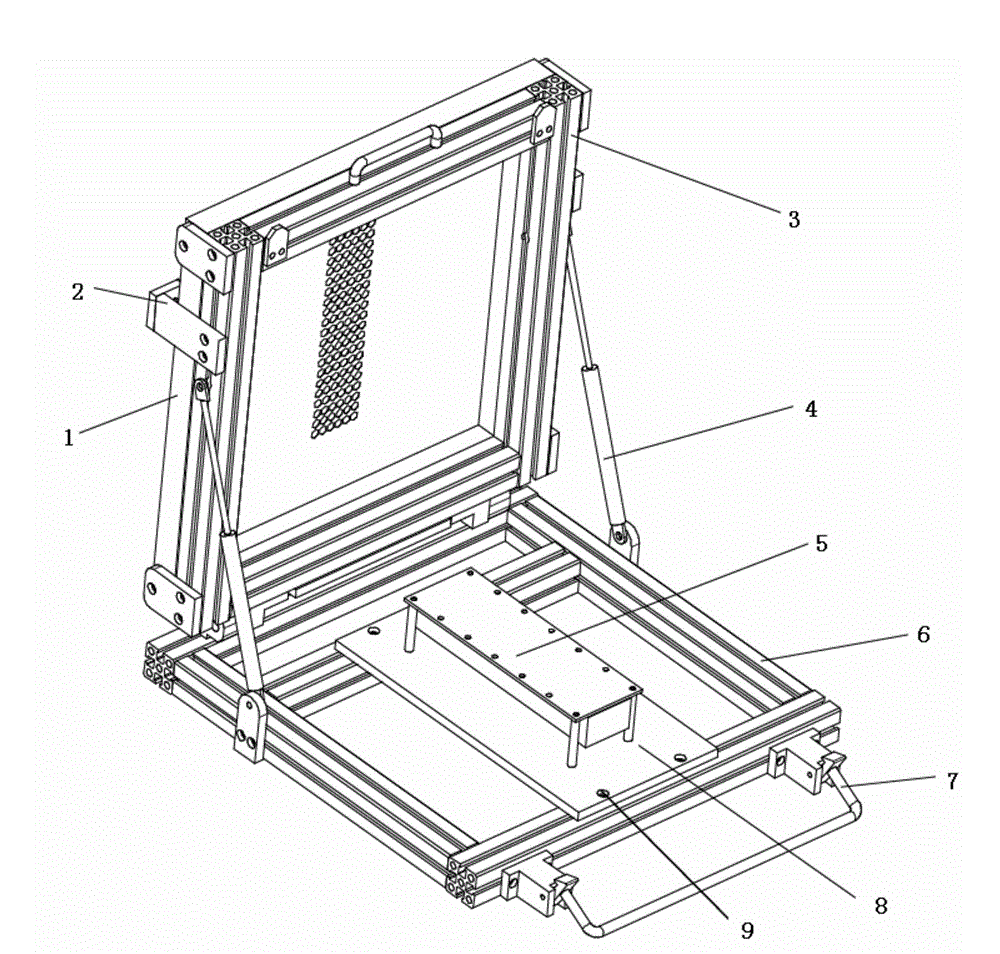

Thermally-conductive silicon grease coating device

The invention discloses a thermally-conductive silicon grease coating device which comprises a main body frame, a silk screen net plate, a silk screen net plate support and a mould block support. The silk screen net plate is inserted into the silk screen net plate support, the mould block support is fixed on the main body frame, the mould block support is fixed with mould blocks which are matched with the silk screen net plate, the silk screen net plate comprises at least one silk screen, and the mould blocks and the silk screens are identical in number and are matched in position. The thermally-conductive silicon grease coating device has the advantages that the silk screen net plate and the mould block support can be replaced, so that the thermally-conductive silicon grease coating device is suitable for thermally-conductive silicon grease coating of various mould blocks; in addition, multiple different silk screens are integrated on one silk screen net plate, and multiple mould blocks can be coated each time, so that the device is especially suitable for simultaneous coating of IGBTs (insulated gate bipolar transistor) of various types, working time and workstations for replacing a coating tool are avoided, consumption of thermally-conductive silicon grease is reduced, production space is saved, coating efficiency, coating quality and coating uniformity are greatly improved, and product quality is improved.

Owner:RENERGY ELECTRIC TIANJIN

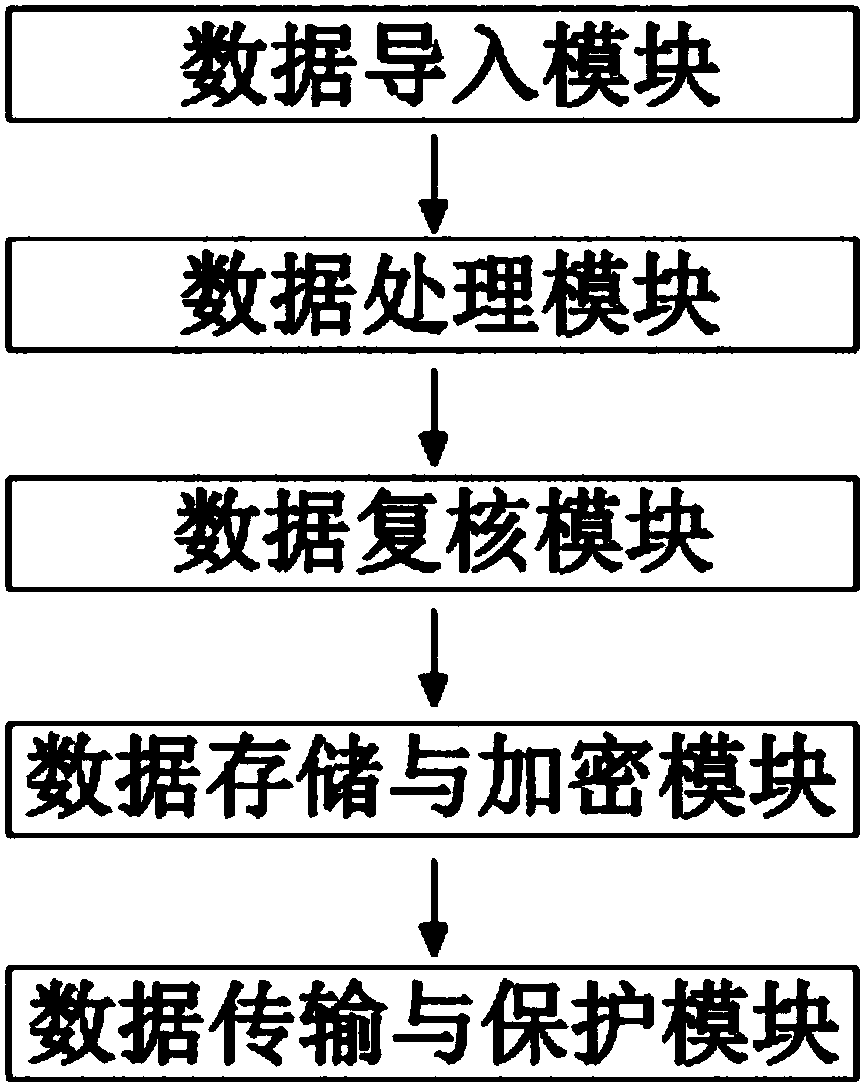

Processing method and processing system for accounting statement

InactiveCN108595404AAvoid lossAvoid Statistical MistakesText processingSpecial data processing applicationsWork periodData operations

The invention discloses a processing method and a processing system for an accounting statement. The processing method comprises the specific steps of (1) data import, wherein data needing statement making is selected first, and then the data is automatically imported into the accounting statement needing processing through a data import module; (2) data processing, wherein data sorting-out and classification are performed on the imported data first, different unit prices or different formulas are set according to different types of data, and then the accounting statement is automatically generated after data operation processing is performed; and (3) data review. Through the processing method and the processing system, data import and input are performed through the data import module, and then data processing and data review are performed through a data processing module; data statistical errors of the statement can be effectively avoided, losses are reduced, an unnecessary trouble is avoided, and an encryption function is achieved; and the processing method is simple and rapid in use, improves working efficiency and shortens working time.

Owner:RIZHAO POLYTECHNIC

Display device and television

InactiveCN103412422AReduce the use of screwsAvoid working hoursTelevision system detailsColor television detailsBackplaneDisplay device

The invention provides a display device and a television. The display device comprises a display panel assembly, a back plate, a rubber frame and a clamping piece. The display panel assembly comprises a display panel and a connecting piece fixedly arranged on the periphery of the back of the display panel. The rubber frame is arranged on the outer periphery of the back plate and fixedly connected with the back plate, a first through hole is formed in the lateral side of the rubber frame, and a gap is arranged between the back plate and the rubber frame. The clamping piece can be accommodated in the first through hole, one end of the clamping piece can be clamped with the connecting piece, and the other end of the clamping piece can be inserted into the gap to enable the display panel and the back plate to be fixedly connected with the rubber frame. By fixedly connecting the display panel assembly, the back plate and the rubber frame through the clamping piece, production and manufacture cost is effectively reduced, production efficiency is improved, and market competitiveness is improved.

Owner:HISENSE VISUAL TECH CO LTD

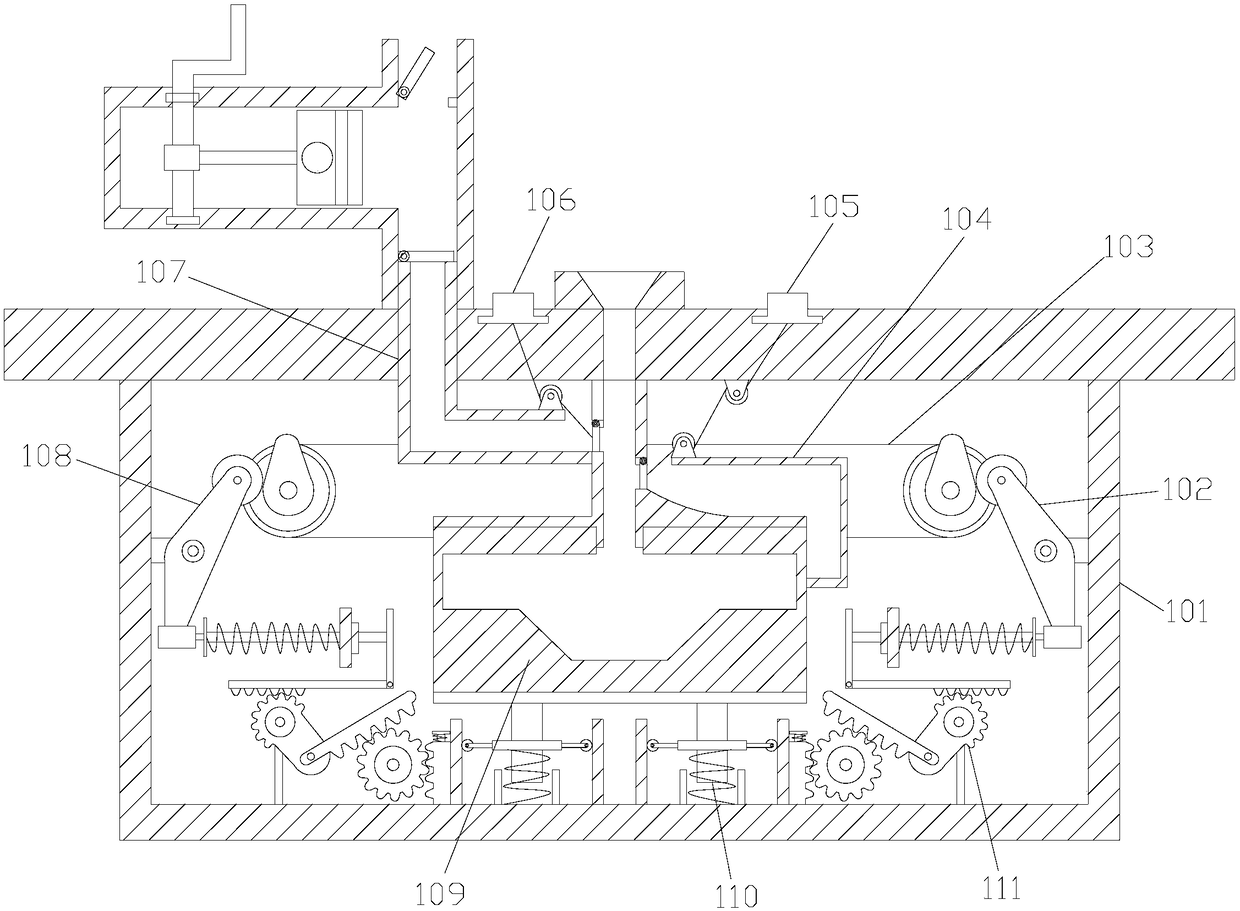

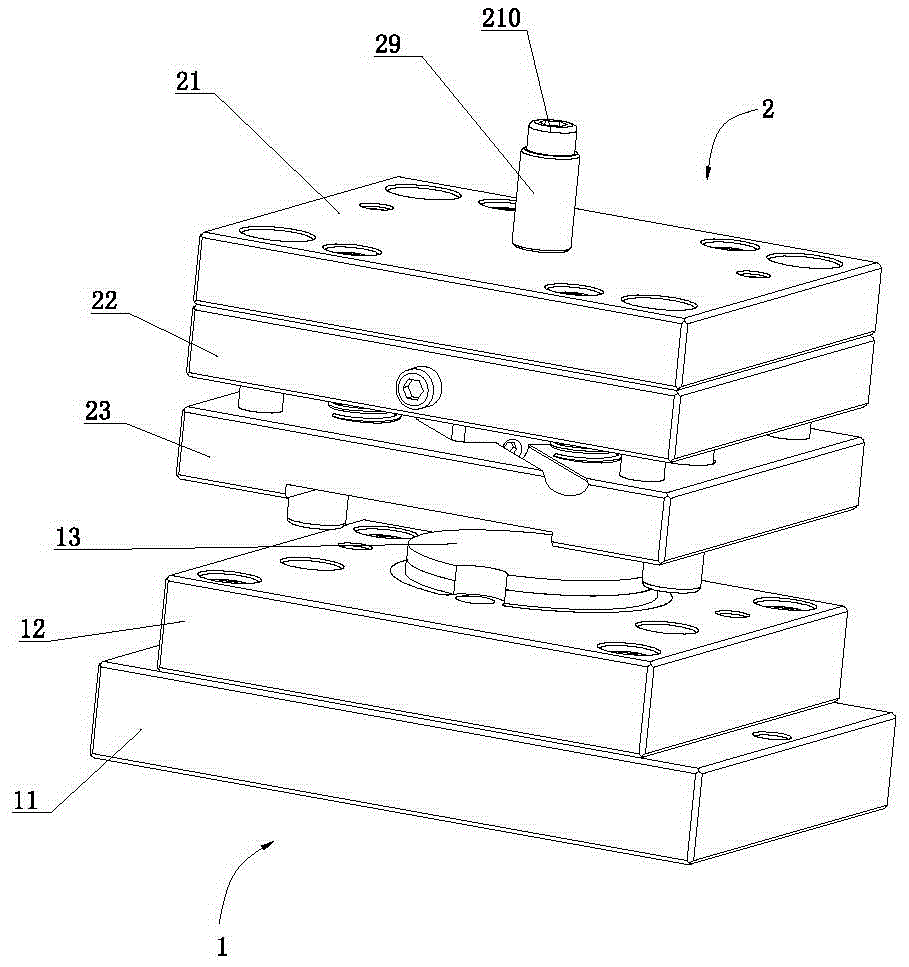

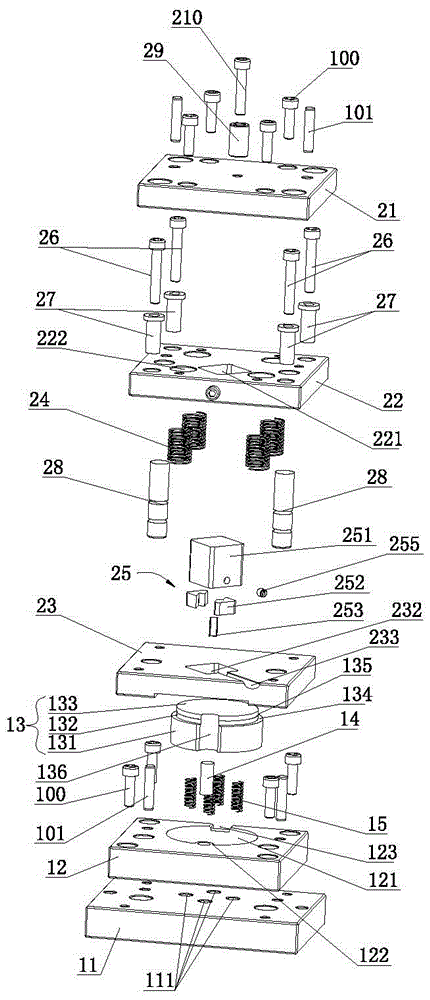

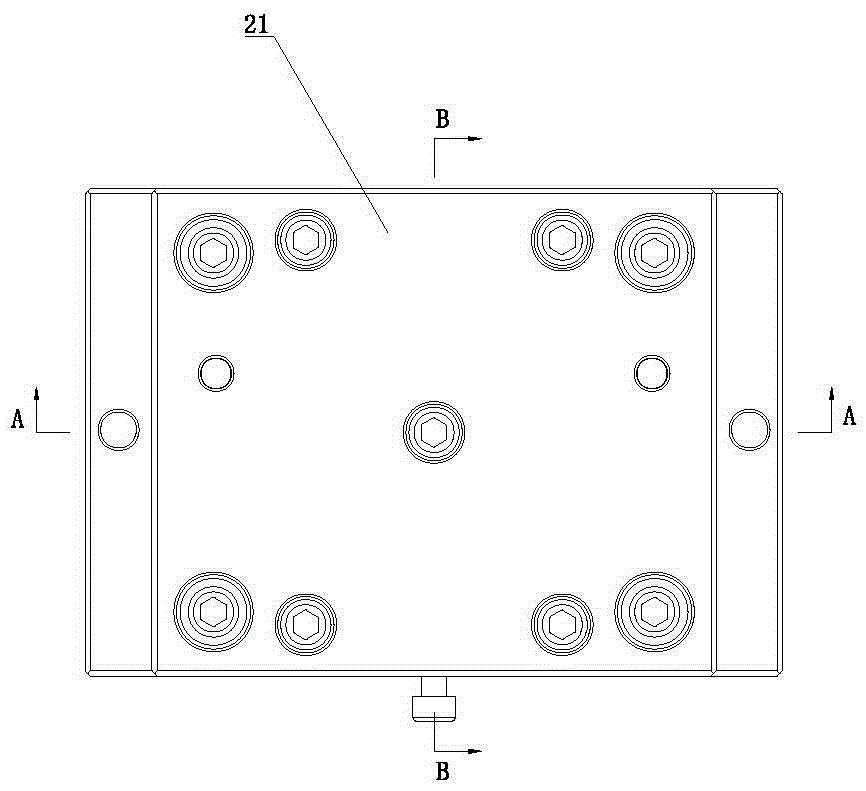

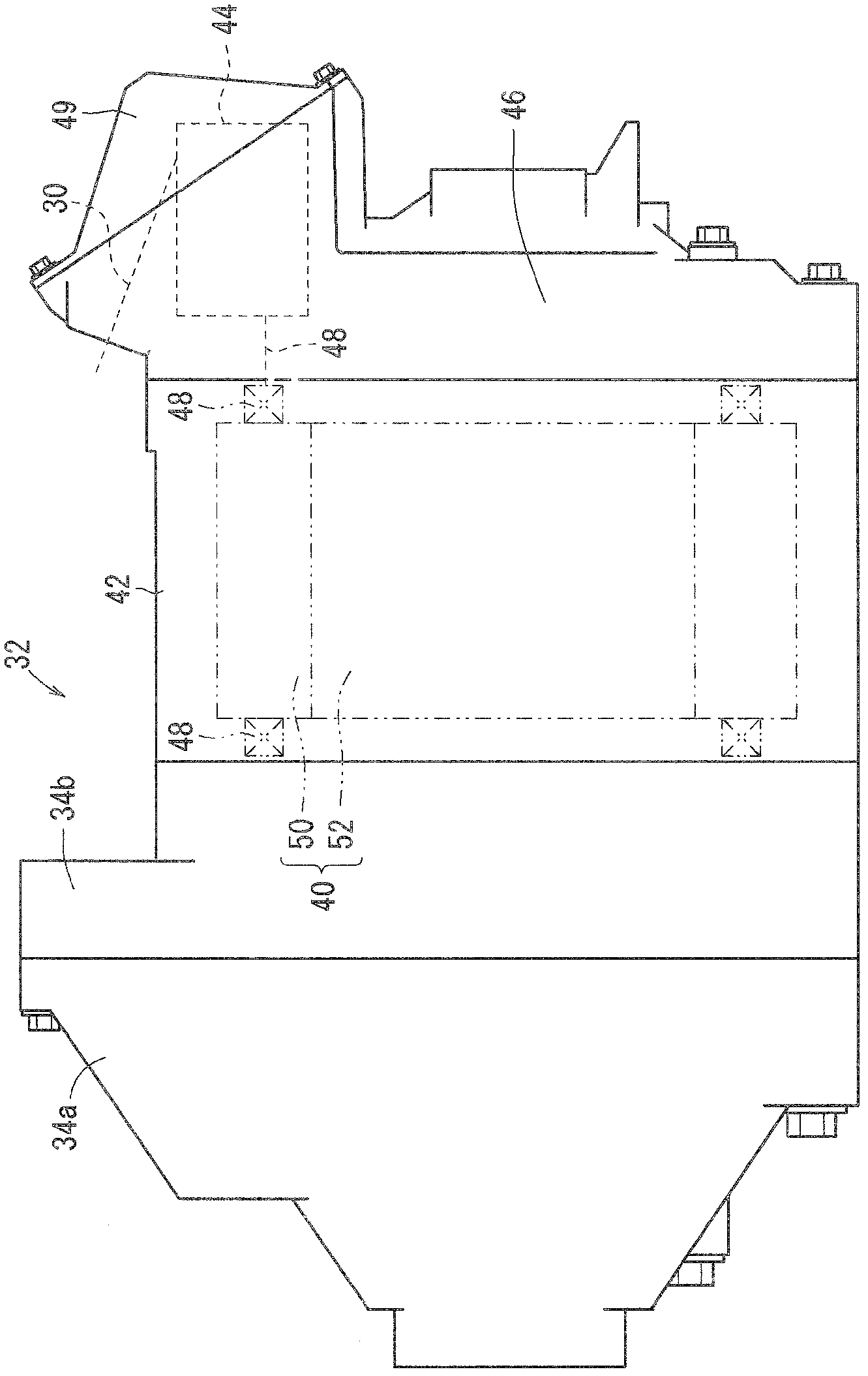

Manufacturing method and equipment for breaking joints of sealing ring

ActiveCN105414308AImprove pass rateAvoid working hoursMetal-working feeding devicesPositioning devicesEngineeringNotching

The invention discloses a manufacturing method and equipment for breaking joints of a sealing ring. The manufacturing equipment comprises a forming die, wherein the forming die comprises a lower die and an upper die; the lower die comprises a lower die seat, a lower die locating seat and a locating seat, the locating seat comprises a connecting portion, a limiting portion and a locating portion which are sequentially connected upwards, the connecting portion, the limiting portion and the locating portion gradually decrease in cross section, and a first elastic member is arranged between the bottom of the connecting portion and the lower die seat. The upper die comprises an upper die seat, an upper die fixing plate, a prepressing plate, a second elastic member and a cutting knife assembly; the cutting knife assembly is fixedly arranged on the upper die fixing plate and corresponds to the position of a yielding gap, the lower end of the cutting knife assembly is provided with a knife edge, and the thickness of the knife edge is 0.1-0.2mm; an accommodating groove which is in positional correspondence to the locating seat is formed in the bottom of the prepressing plate, and the accommodating groove is 0.2-0.5mm higher than the sealing ring. According to the manufacturing method, the forming die is used for forming the breaking joints. According to the method and the equipment, the breaking joints with small clearance and high accuracy can be formed on the sealing ring.

Owner:GUANGZHOU QUANDE MACHINERY TECH CO LTD

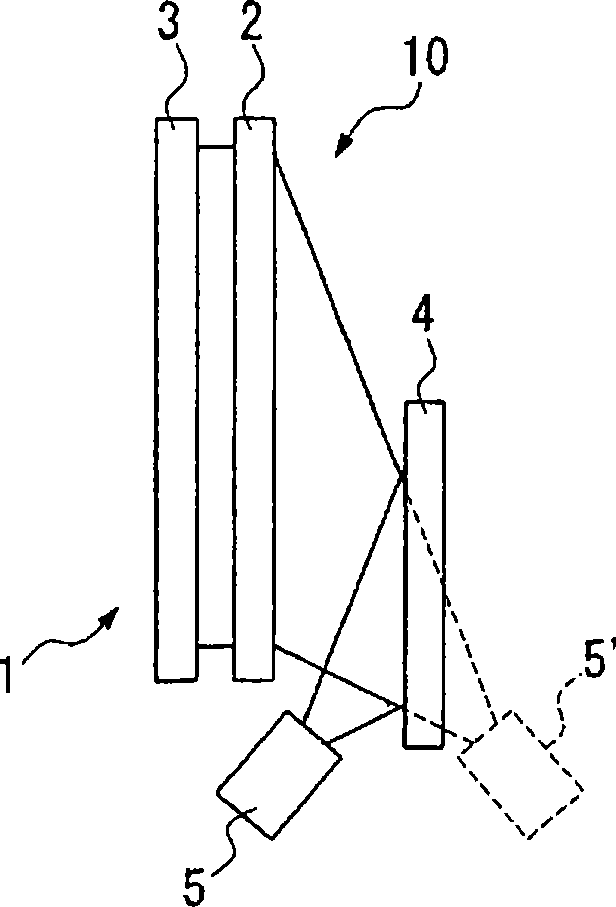

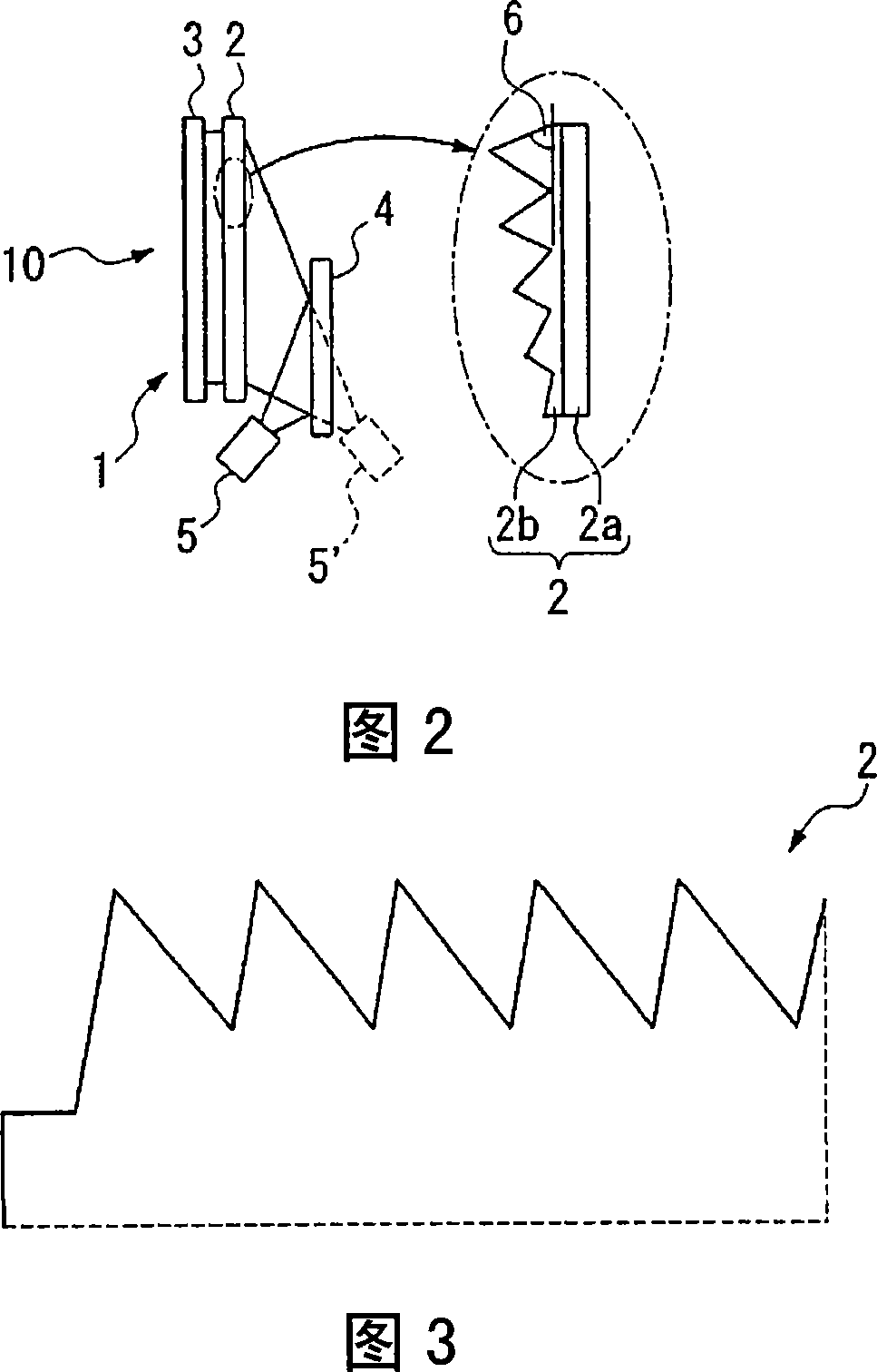

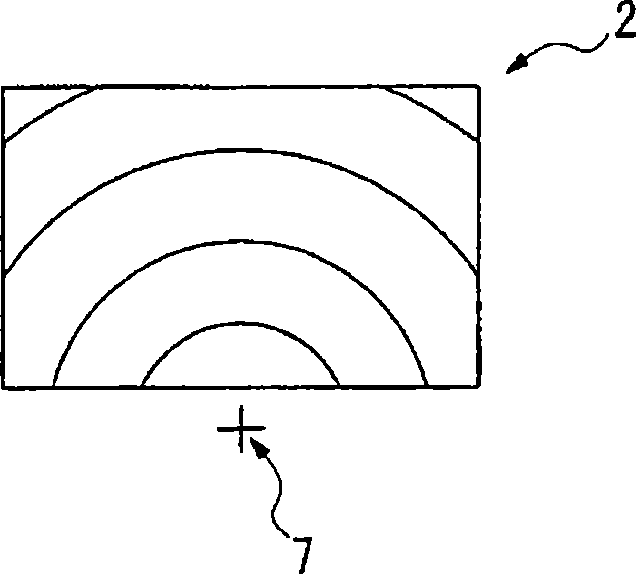

Fresnel lens, transmission screen, and rear projection-type display device using the lens

InactiveCN1867864AShorten the projection distanceQuality improvementTelevision system detailsDiffusing elementsFresnel lensOptical axis

A rear projection-type display device has a Fresnel lens sheet where a lens pattern having a Fresnel surface as a light ray transmissive surface and a rise surface as a non-light ray transmissive surface are concentrically formed and where the optical axis, the center of the lens pattern, of a Fresnel lens is positioned outside the Fresnel lens sheet; a transmission screen having a light diffusion plate; a projector capable of projecting an image on the transmission screen; and a reflection mirror provided between the projector and the transmission screen. The reflection mirror is installed at a substantially middle position between the projector and the transmission screen.

Owner:TOPPAN PRINTING CO LTD

Loom with barre preventing function

Owner:TSUDAKOMA KOGYO KK

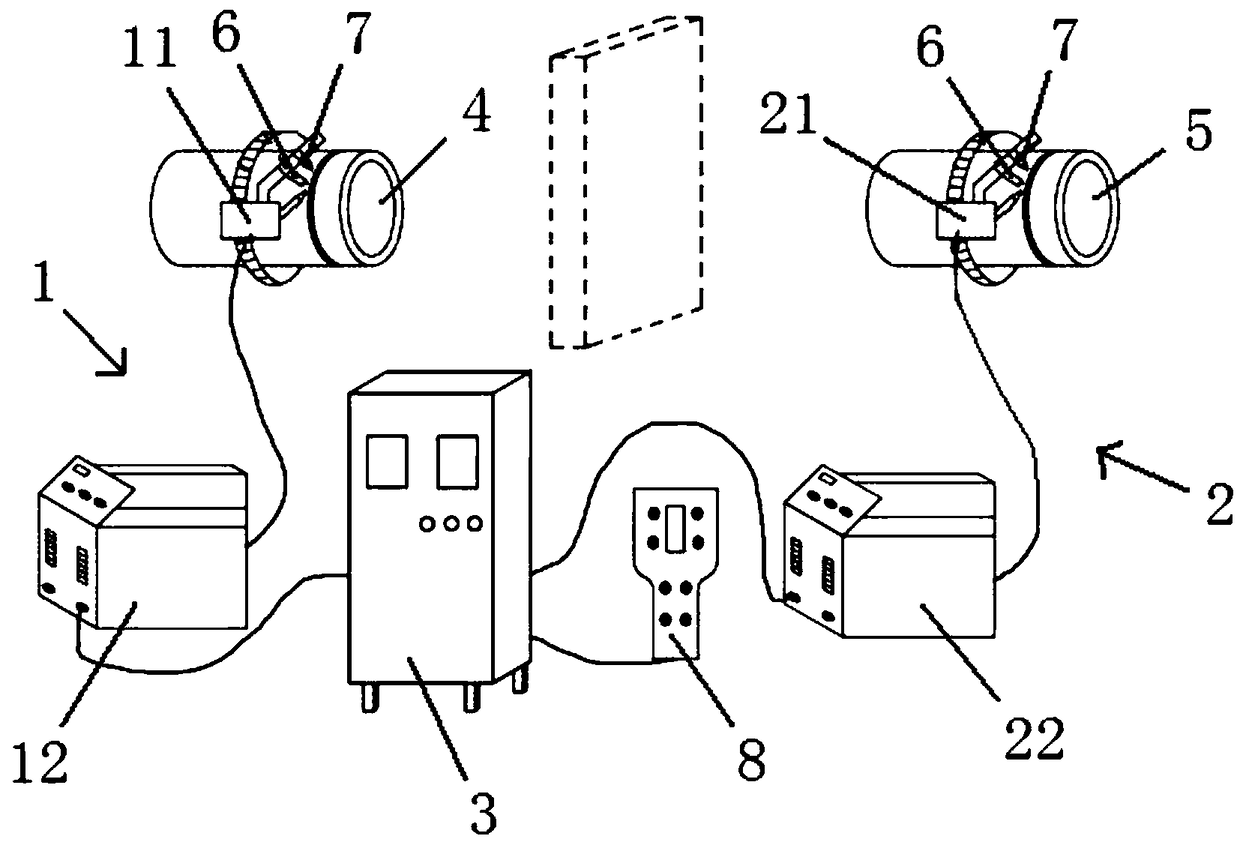

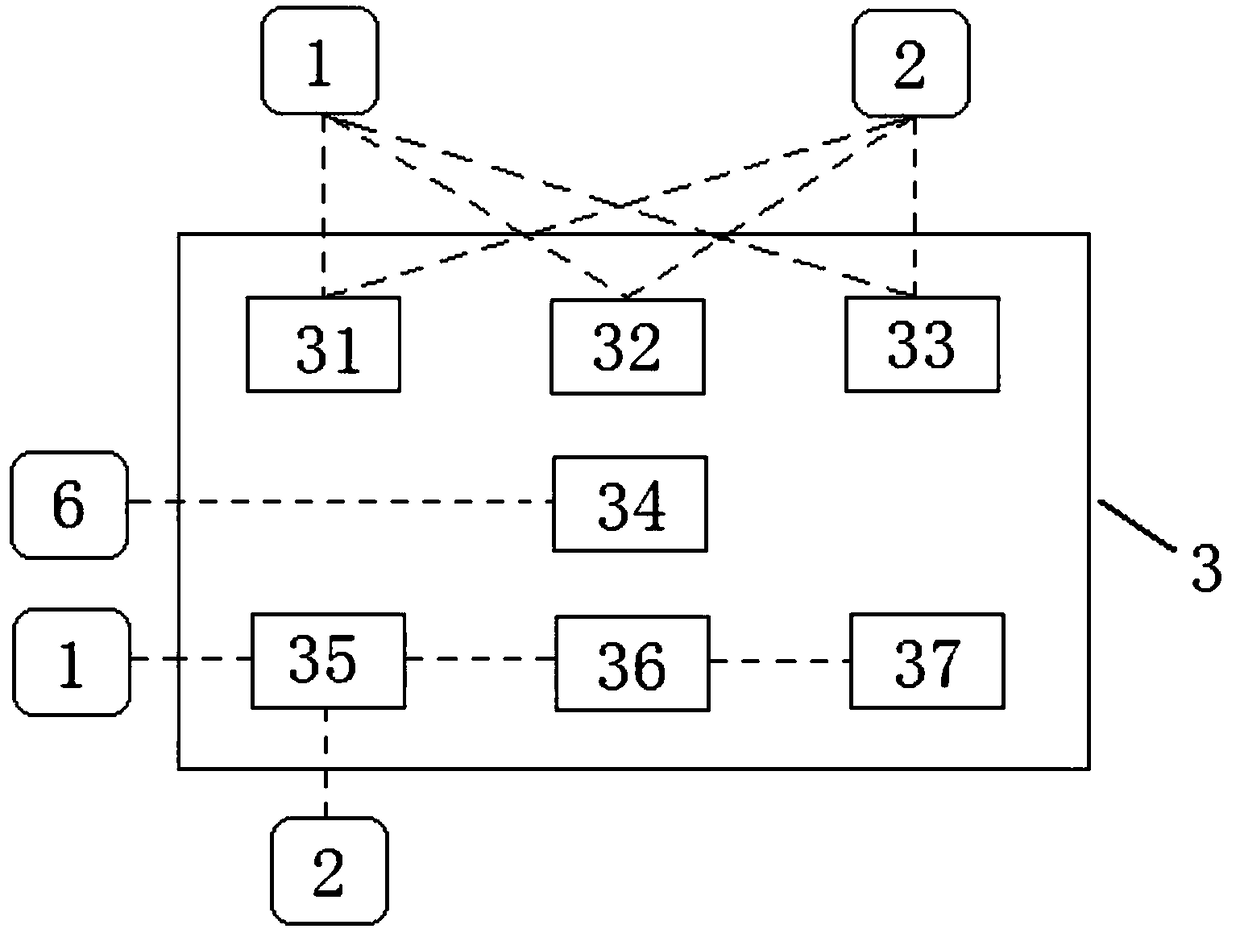

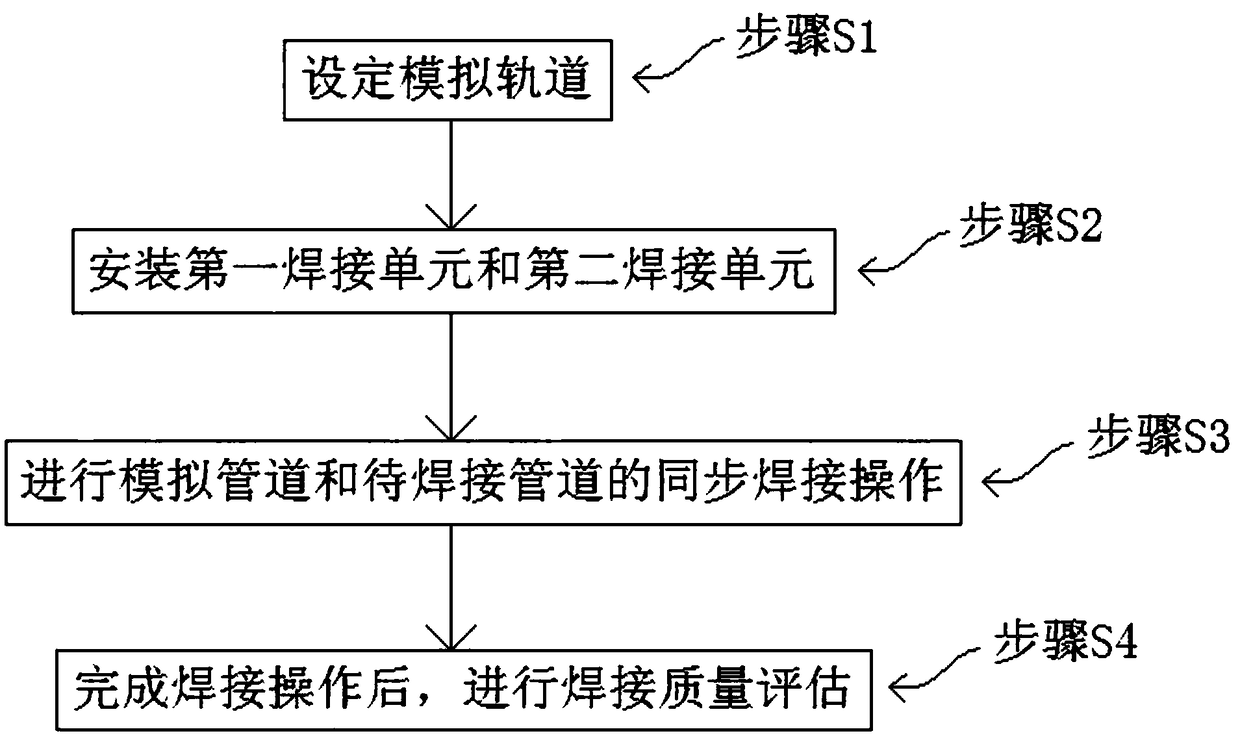

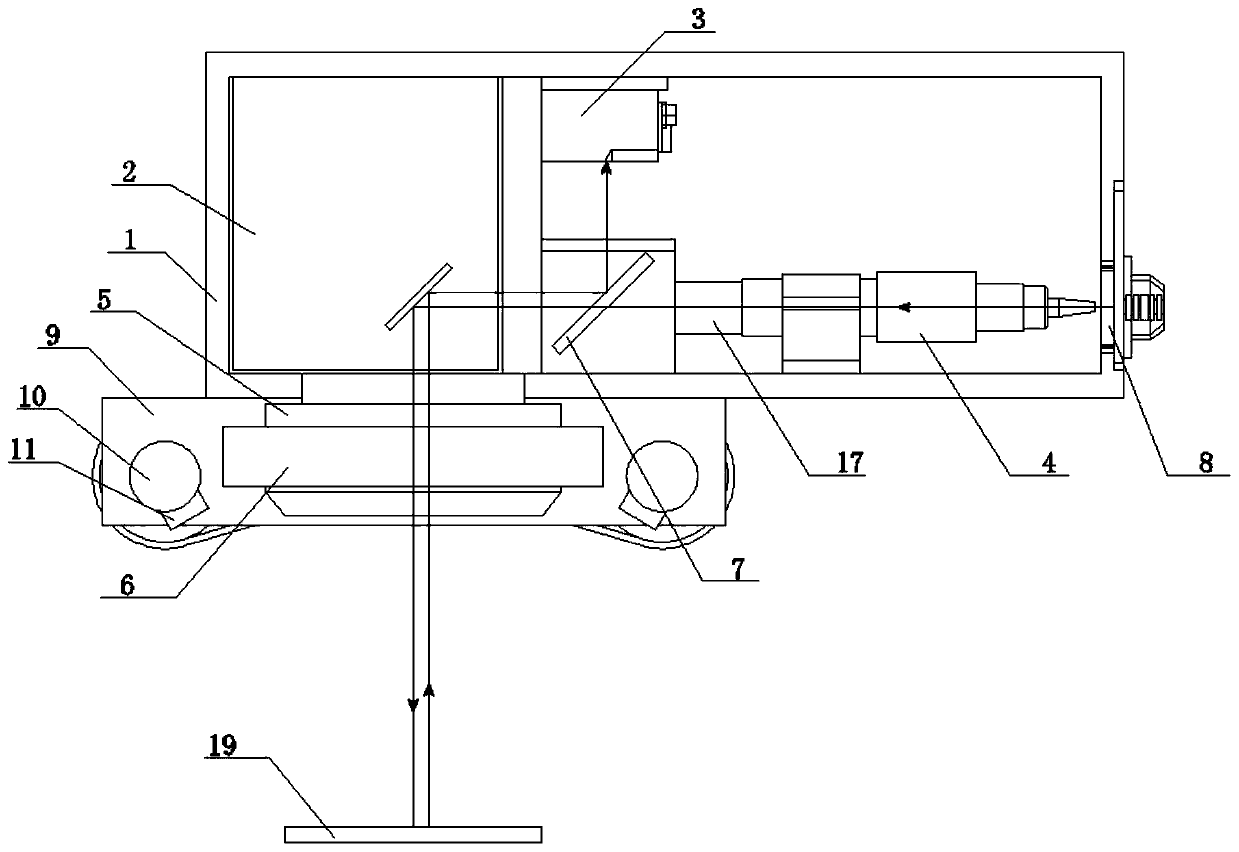

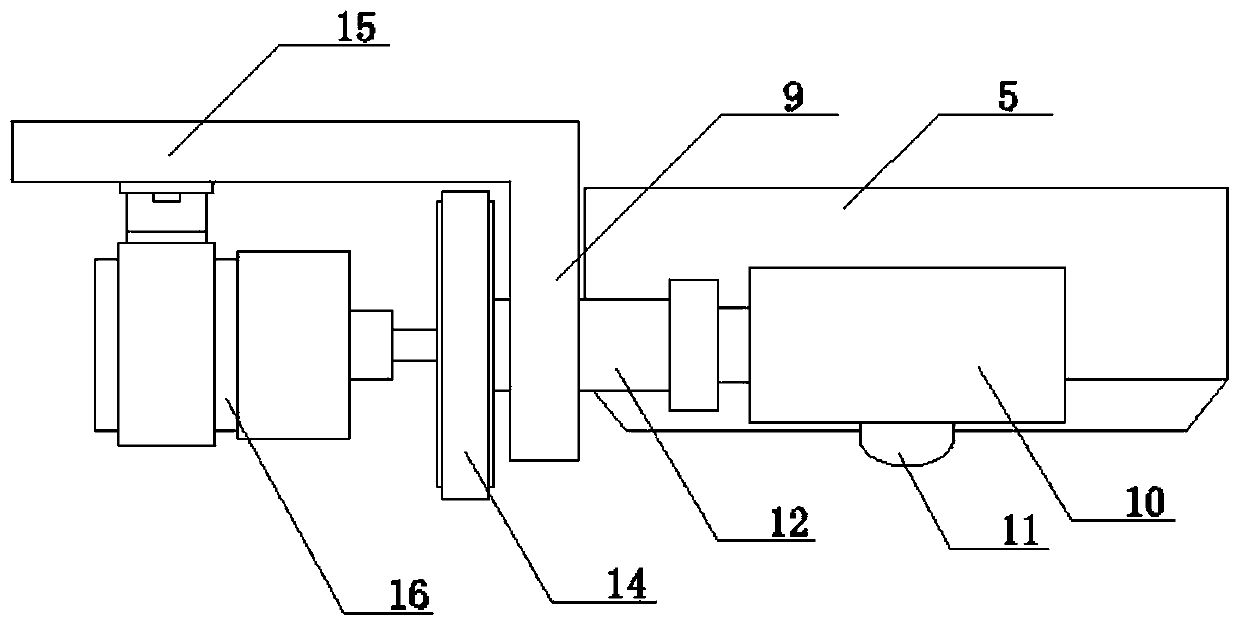

Welding system and method of nuclear engineering pipe under radiation environment

InactiveCN109500490AAvoid welding operationsAchieving health protectionWelding/cutting auxillary devicesAuxillary welding devicesPipe weldingControl unit

The invention belongs to the technical field of nuclear engineering pipeline welding. In order to achieve smooth repairing and welding of the nuclear engineering pipeline under the radiation environment and ensure the efficiency and quality of the welding operation, the invention discloses a welding system and method of the nuclear engineering pipe under the radiation environment. The welding system includes a first welding unit, a second welding unit and a control unit; the first welding unit is connected to the pipeline to be welded, the second welding unit is connected to a simulation pipeline, and the control unit is simultaneously connected to the first welding unit and the second welding unit and controls a first welding machine and a second welding machine to perform synchronous welding operation; and the simulation pipeline is located in a non-radiation area, and the welding condition is the same as the welding condition of the pipeline to be welded. When the welding system isused for repairing and welding the nuclear engineering pipeline under the radiation environment, the standing time of an operator in the radiation environment can be reduced, the protection of the operator can be improved, the welding operation can be completed quickly and smoothly, and the welding efficiency and quality are improved.

Owner:CHINA NUCLEAR IND 23 CONSTR

Code reading and coding all-in-one machine

InactiveCN111482698AEasy to installQuick installationLaser beam welding apparatusProduction lineGalvanometer

The invention relates to the technical field of laser marking machine, in particular to a code reading and coding all-in-one machine which comprises a shell. A galvanometer scanning head, a code reading camera, a laser output isolator and a half transparent and half reflecting mirror are arranged in the shell; a field lens is arranged at the lower end of the shell and is connected with the galvanometer scanning head; a visible light source and a visible light focusing assembly are connected to the lower end of the field lens; a laser input port is fixedly connected to one end of the shell; a laser light input from the laser input port is transmitted to the surface of a workpiece under the field lens by sequentially passing through the laser output isolator, the half transparent and half reflecting mirror and the galvanometer scanning head; and a visible light emitted by the visible light source is reflected through the workpiece and transmitted to the half transparent and half reflecting mirror through the field lens and the galvanometer scanning head, and is reflected to the code reading camera through the half transparent and half reflecting mirror. Through arranging the visiblelight focusing assembly, invisible laser focal points can be displayed through the visible light, and the position of a laser focal point can be quickly found through a visible light focal point whena production line product is replaced.

Owner:WUXI BOLN LASER TECH

Water-soluble fertilizer having effects for dredging pipeline and resisting obstruction used for drip irrigation system and application method thereof

InactiveCN107266205AImprove solubilityAvoid condensationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDrip irrigationWater soluble

The invention provides a water-soluble fertilizer having effects for dredging pipeline and resisting obstruction used for a drip irrigation system, which belongs to the field of an agricultural fertilizer. The water-soluble fertilizer comprises the following components: 2-7 parts of a chelating agent, 3-8 parts of a pH conditioning agent, 50-95 parts of a scale inhibitor, and 1-1.5 parts of a sanitizing agent; wherein, the scale inhibitor is one or more of potassium pyrophosphate, tripotassium phosphate, ATMP, HEDP sodium salt or PBTCA.Na4; while fertilizing, the water-soluble fertilizer has the effects for dredging pipeline and resisting scales.

Owner:陕西彤山生物科技有限公司

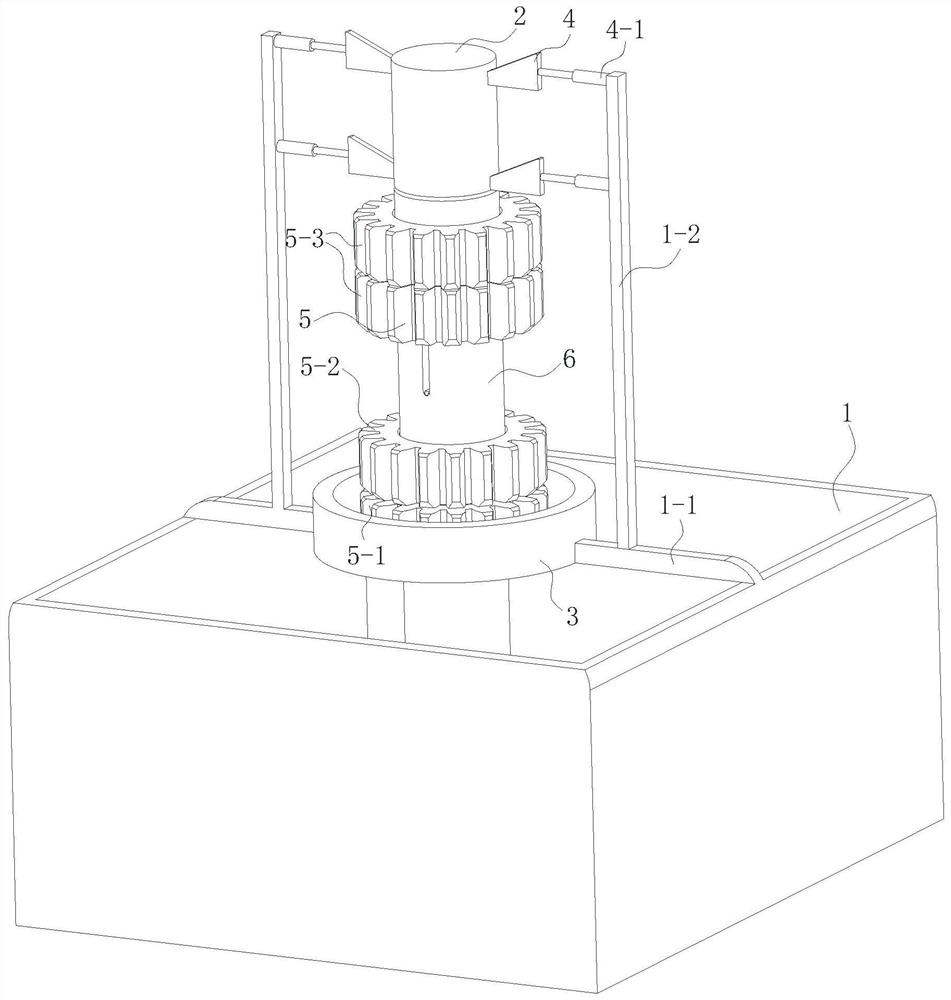

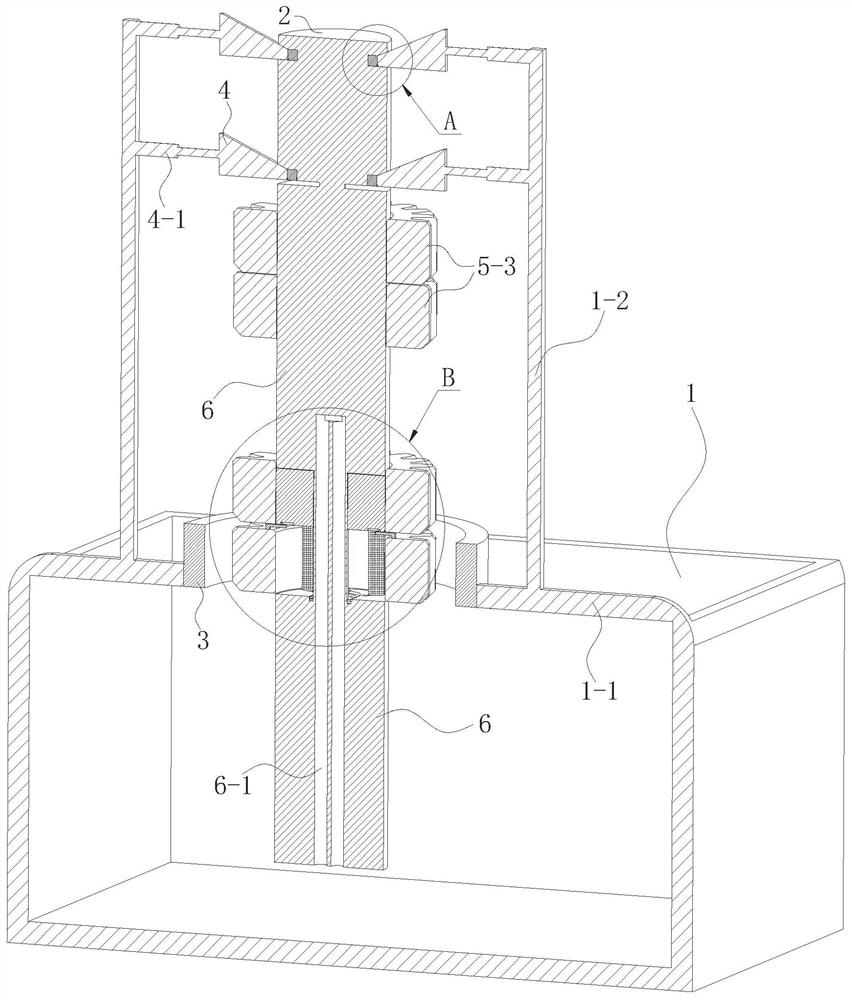

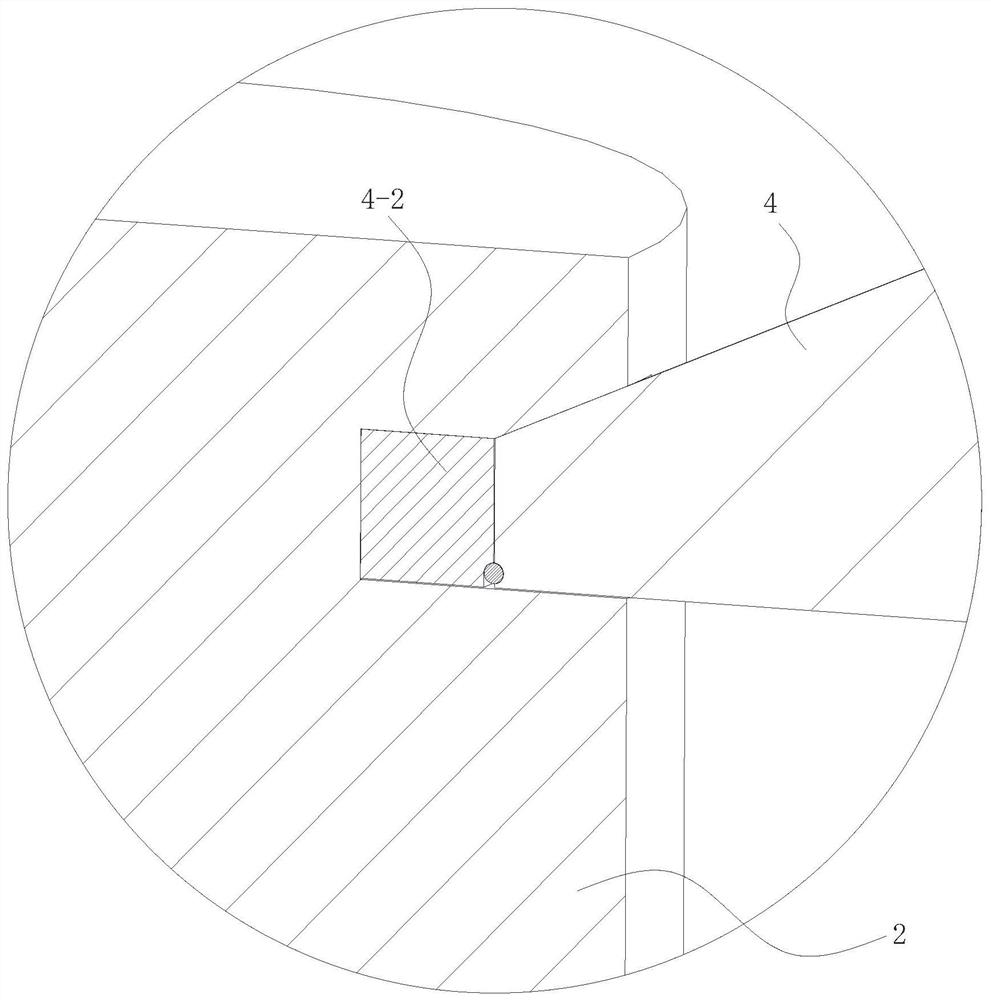

Quenching equipment for gear machining and quenching process of quenching equipment

InactiveCN113462876APrecision quenchingQuality improvementFurnace typesIncreasing energy efficiencyGear wheelInduction heater

The invention discloses quenching equipment for gear machining in the technical field of gear machining. The quenching equipment comprises a cooling pond, a high-frequency magnetic induction heater, gears and a rotating shaft, and is characterized by further comprising a fixed shaft, wedge-shaped supporting plates, an electromagnet, an annular limiting rod, a sliding column and a limiting connecting rod; the high-frequency magnetic induction heater is fixedly installed at the upper end of the cooling pond, the four wedge-shaped supporting plates are vertically distributed in pairs and symmetrically arranged above the high-frequency magnetic induction heater relative to the axis of the high-frequency magnetic induction heater, the wedge-shaped supporting plates are all connected with the fixed shaft in a clamped mode, and the fixed shaft and the high-frequency magnetic induction heater are coaxial; the lower end of the rotating shaft is rotationally mounted at the lower end of the fixed shaft, and the multiple gears sleeve the rotating shaft; and the wedge-shaped supporting plates, the electromagnet, the annular limiting rod, the sliding column and the limiting connecting rod are all mounted on the rotating shaft and used for controlling the positions of the gears on the rotating shaft. Compared with a conventional method for controlling the quenching degree through time, the quenching time is controlled through the quenching degree, so that the quality of the gears is stable, and the quality is high.

Owner:黄林枢

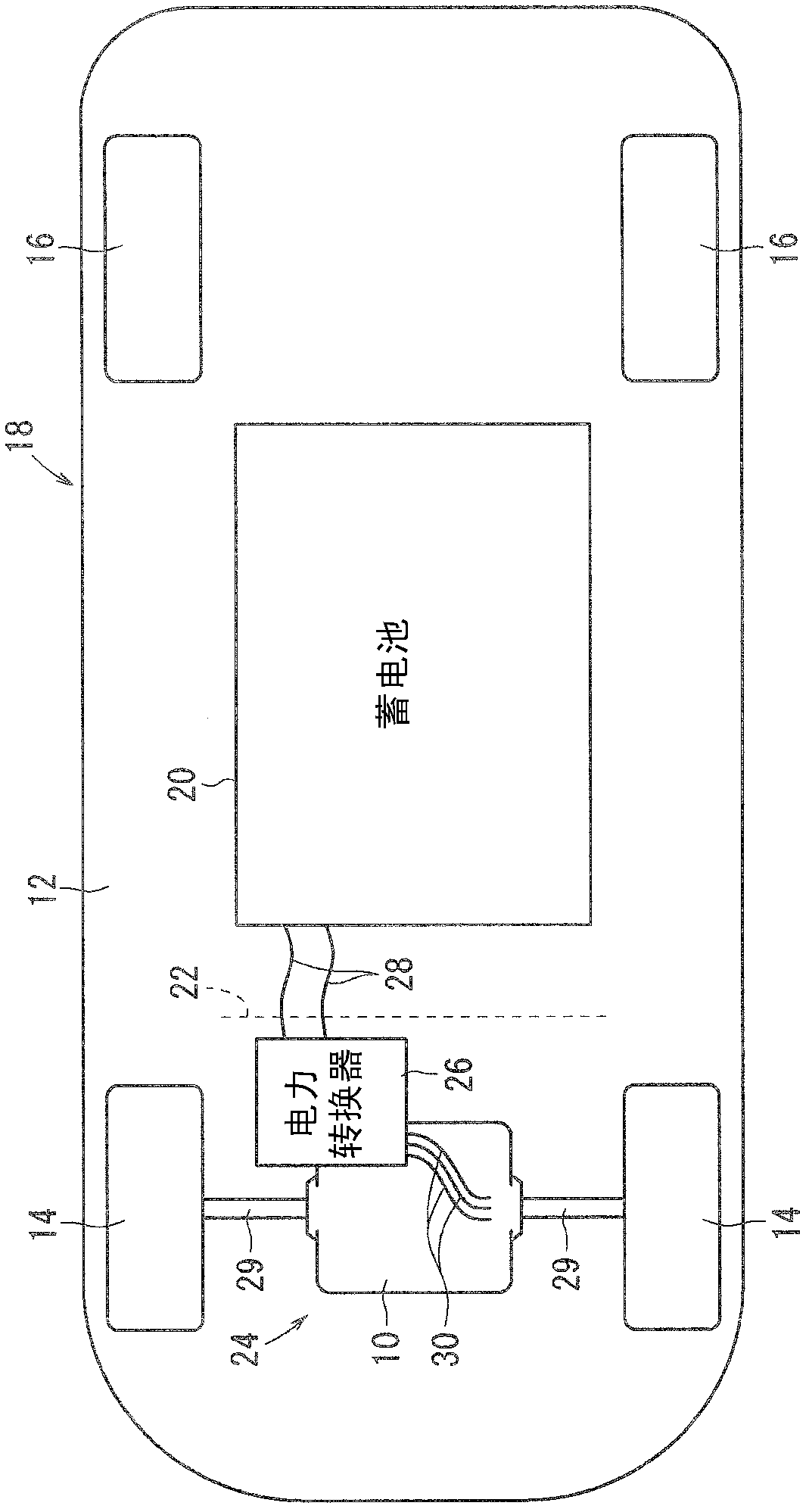

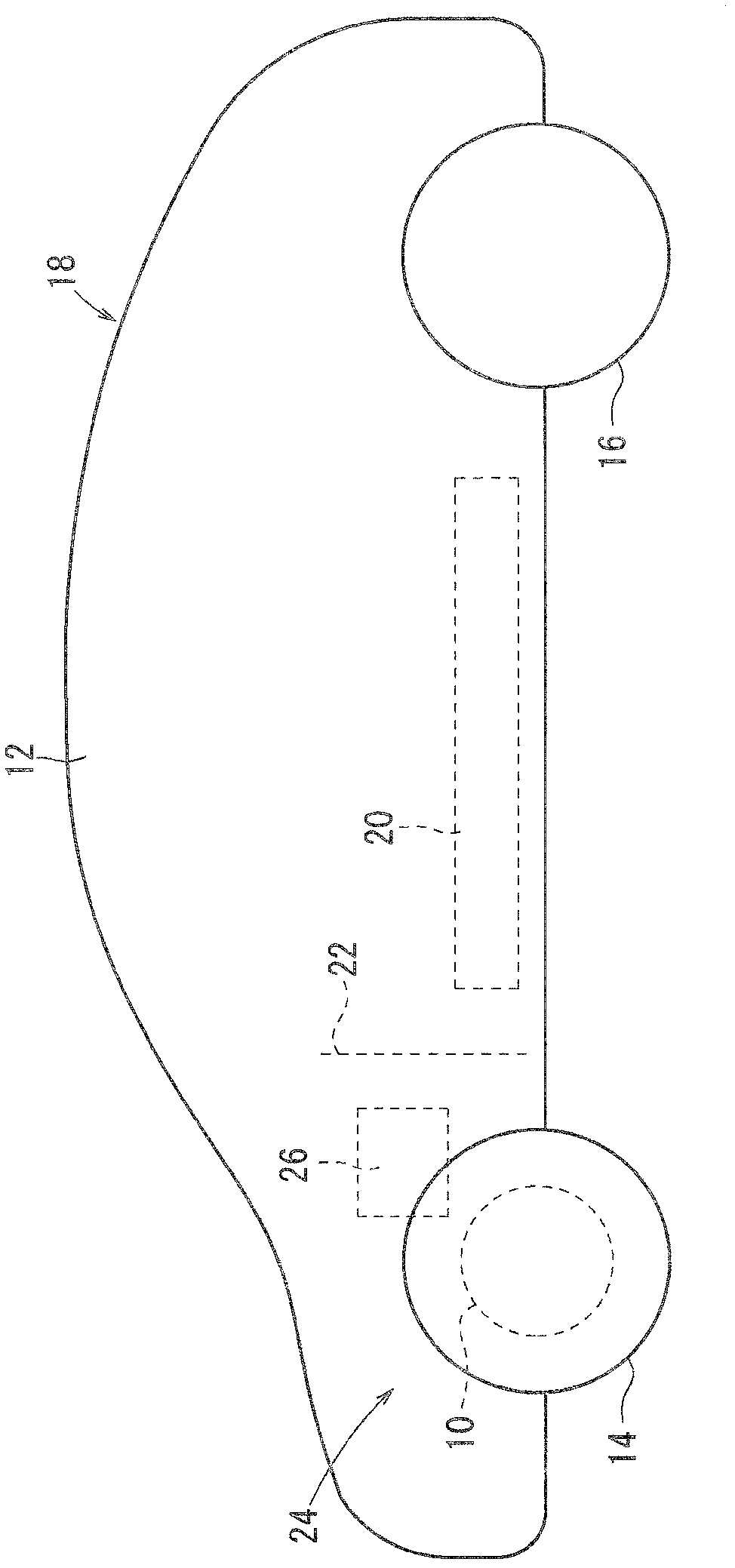

Installation mechanism of charging pile with temperature detection function and using method thereof

InactiveCN112158089AExtended service lifeReduce consumptionCharging stationsElectric vehicle charging technologyEngineeringStructural engineering

The invention belongs to the technical field of charging piles, and particularly relates to an installation mechanism of a charging pile with a temperature detection function and a using method thereof. The charging pile installation mechanism comprises a bottom plate, two sets of universal wheels are arranged below the bottom plate, the upper surface of each universal wheel is fixedly connected with the upper surface of the bottom plate, the upper surface of the bottom plate is fixedly connected with a shell, a collecting box is fixedly connected with the right side face of the shell, and thebottom face of the collecting box is fixedly connected with the upper surface of the bottom plate. By arranging a temperature sensor, when the temperature in the shell reaches a certain value, an electric signal can be transmitted to a single-chip microcomputer, the single-chip microcomputer matches a time relay to start an exhaust fan, heat in the shell is exhausted, and the problem that the service life of the charging pile is shortened due to the fact that the charging pile does not have the temperature detection and cooling functions is solved; and the exhaust fan can be turned off at regular time by utilizing the time relay, and the exhaust fan is started again when the temperature sensor senses the high temperature again, so that the consumption of electric quantity is reduced.

Owner:大庆辉谷能源科技有限公司

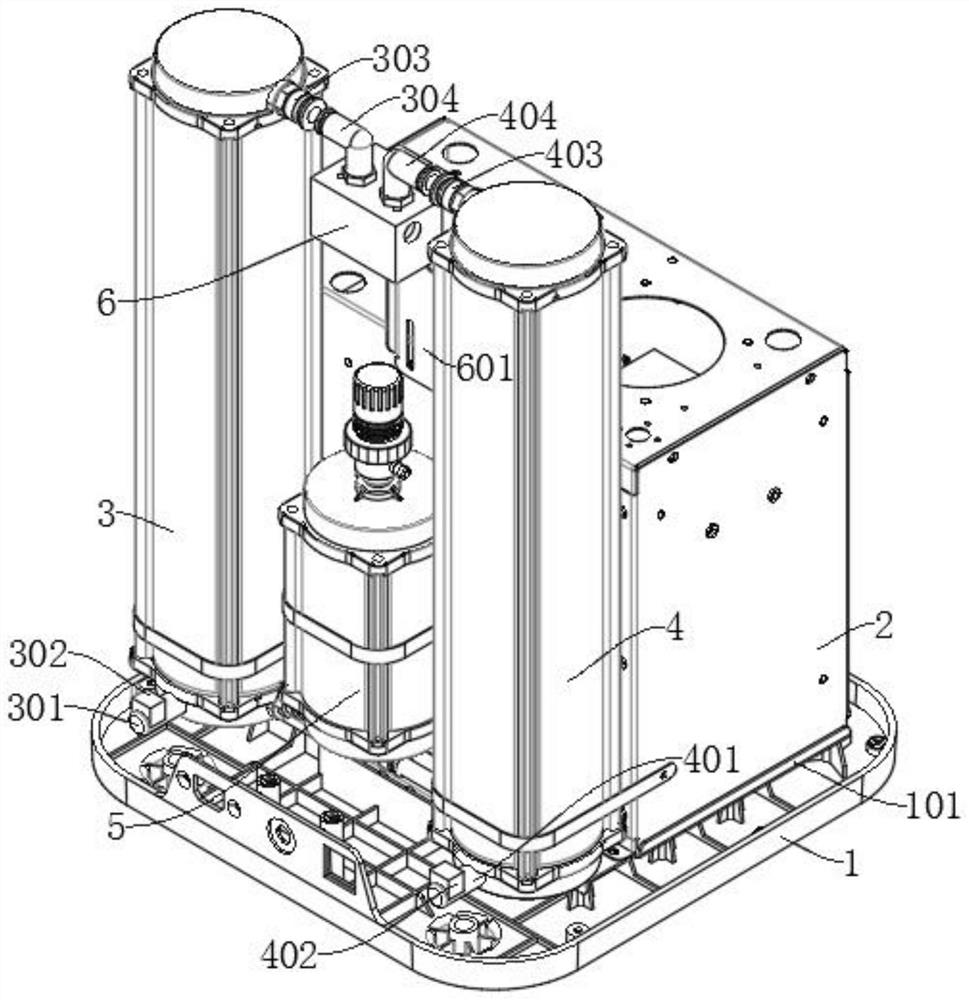

Oxygen generator solenoid valve control structure and control system thereof

PendingCN113694689AImprove the problem affected by the altitude of the operating environmentAvoid working hoursOperating means/releasing devices for valvesDispersed particle separationMolecular sieveSolenoid valve

The invention discloses an oxygen generator electromagnetic valve control structure and a control system thereof, and belongs to the field of oxygen generators. The control structure comprises a base and a shell, wherein an air compressor body is connected into the shell, a molecular sieve tower A and a molecular sieve tower B are connected to the shell, and an oxygen output pipe A and an oxygen output pipe B are arranged at the bottom of the molecular sieve tower A and the bottom of the molecular sieve tower B respectively. An air pressure sensor A and an air pressure sensor B are respectively arranged on the oxygen output pipe A and the oxygen output pipe B; a system electromagnetic valve is arranged at the top of the shell, and the air pressure sensor A and the air pressure sensor B are both in signal connection with the system electromagnetic valve. According to the invention, molecular sieves in the molecular sieve tower A or the molecular sieve tower B can be controlled to always perform corresponding actions at the optimal adsorption or desorption pressure, the working efficiency of an oxygen generation system can be effectively improved by more than 15%, and meanwhile, the problem that the current oxygen generator is influenced by the altitude of the operating environment is greatly improved.

Owner:HEFEI MEILING PURIFYING EQUIP

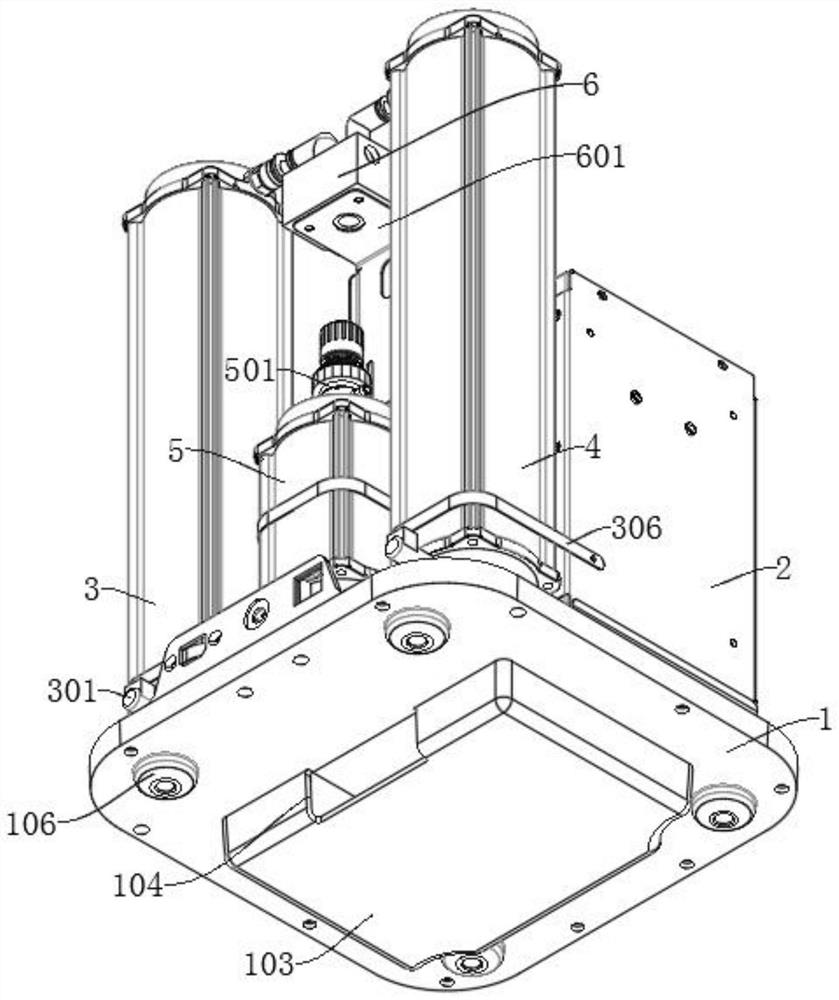

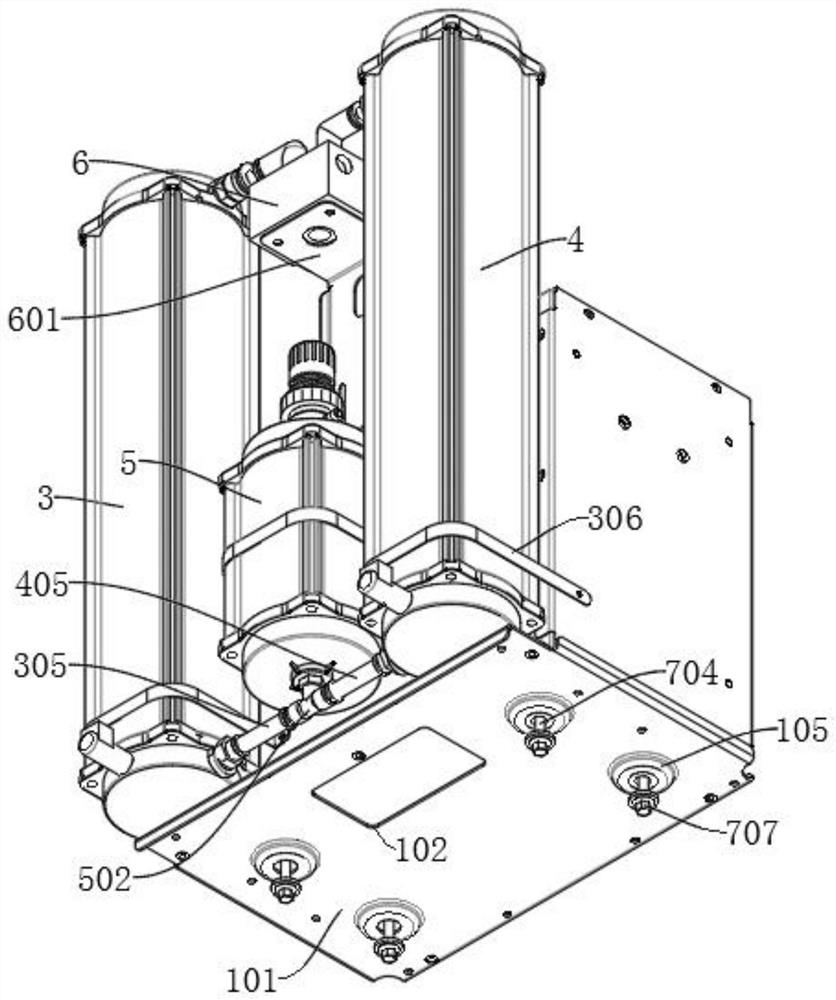

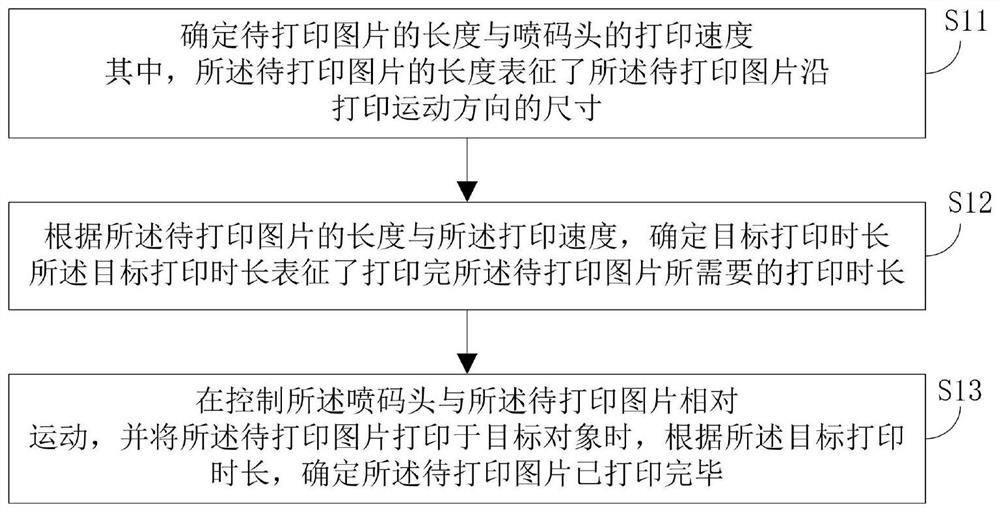

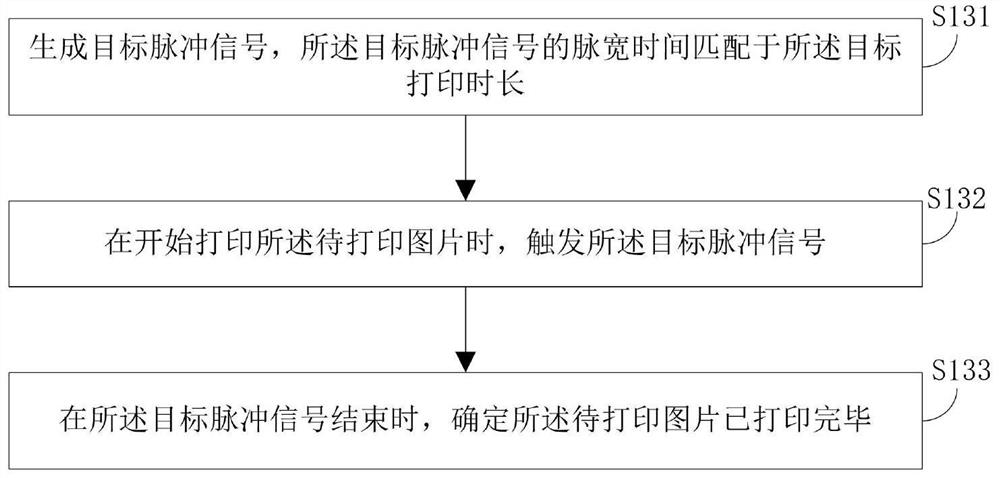

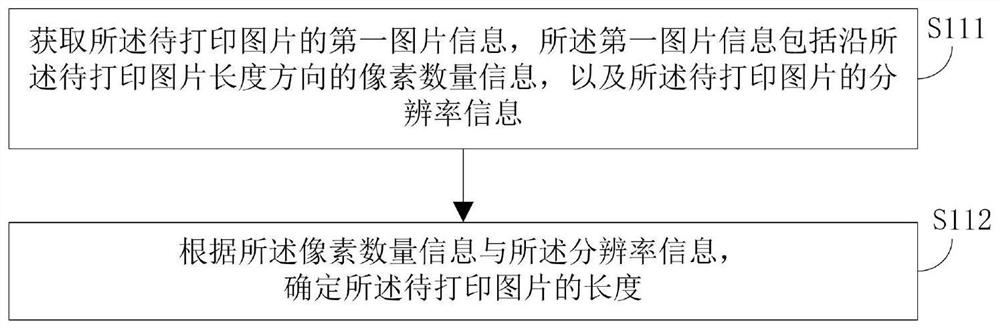

Code spraying printing control method, device and equipment, medium and laser cutting system

ActiveCN112895716AAvoid working hoursImprove printing efficiencyPrintingLaser beam welding apparatusEngineeringLaser cutting

The invention provides a code spraying printing control method, device and equipment, a medium and a laser cutting system. The method comprises the steps that the length of a to-be-printed picture and the printing speed of a code spraying head are determined, wherein the length of the to-be-printed picture represents the size of the to-be-printed picture in the printing motion direction; according to the length of the to-be-printed picture and the printing speed, target printing duration is determined, wherein the target printing duration represents the printing duration required for printing the to-be-printed picture; and when the code spraying head and the to-be-printed picture are controlled to move relatively and the to-be-printed picture is printed on a target object, it is determined that the to-be-printed picture is printed according to the target printing duration.

Owner:上海柏楚数控科技有限公司

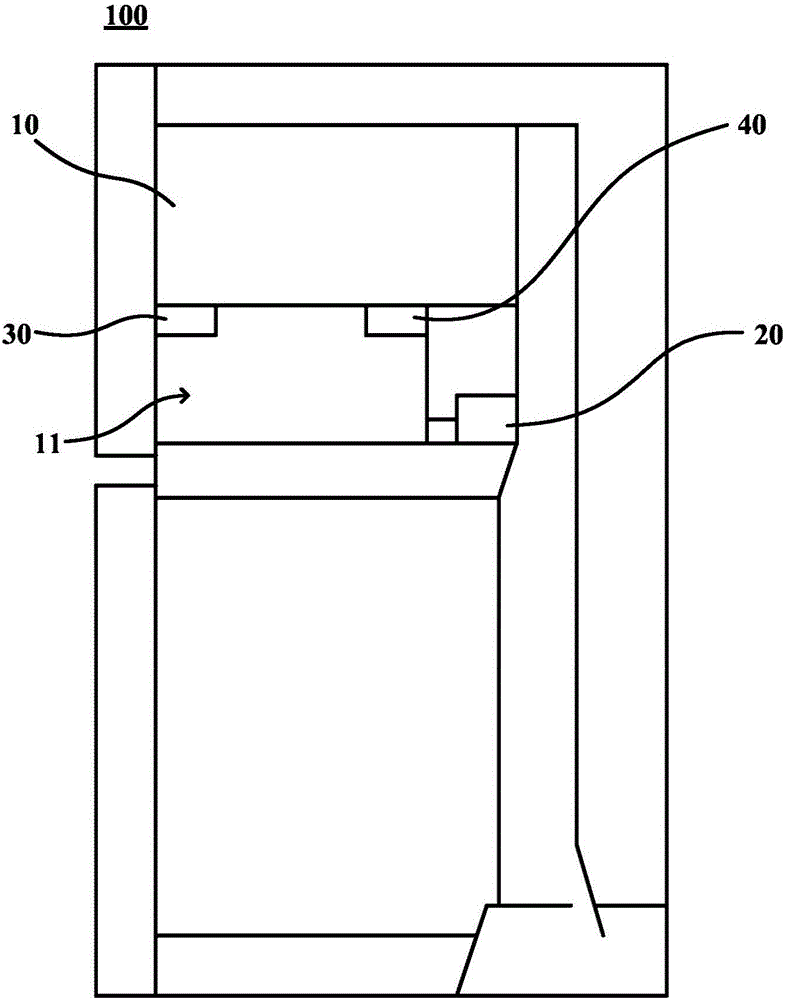

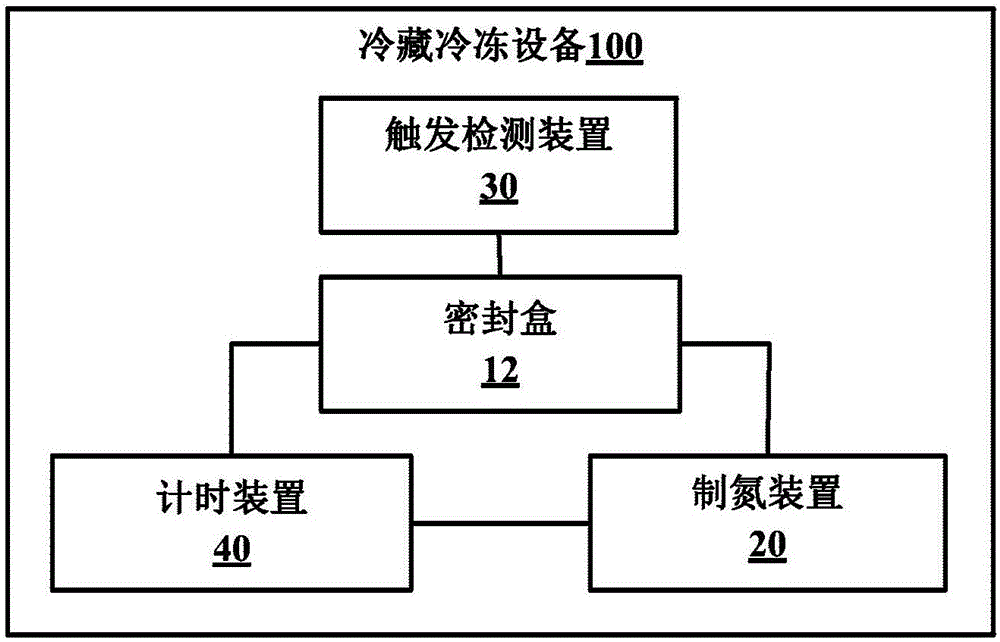

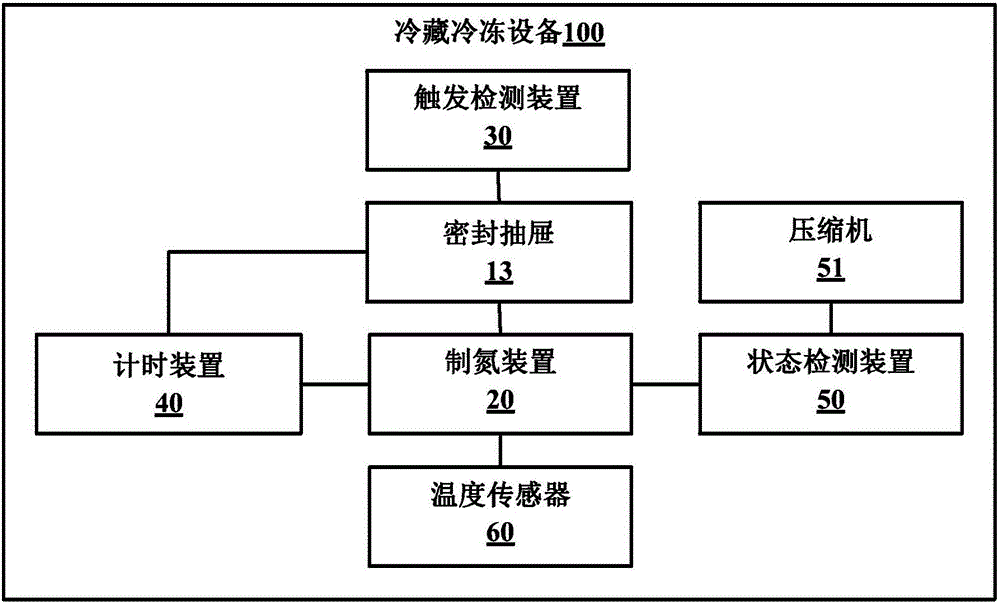

Nitrogen generation control method for refrigerating and freezing equipment and refrigerating and freezing equipment

ActiveCN106288637ALow costAvoid working hoursLighting and heating apparatusCooling fluid circulationNitrogen gasEngineering

The invention provides a nitrogen generation control method for refrigerating and freezing equipment and the refrigerating and freezing equipment. The nitrogen generation control method for the refrigerating and freezing equipment comprises the steps that trigger signals of opening and closing a sealed space are detected; it is determined that the sealed space is opened according to the trigger signals, and after the sealed space is closed for first preset time, a nitrogen generation device is controlled to operate for second preset time so as to provide nitrogen for the sealed space; and when no trigger signal is detected in third preset time after the nitrogen generation device completes nitrogen generation, the nitrogen generation device is controlled to operate for fourth preset time so as to compensate for nitrogen naturally leaked out of the sealed space. Through the scheme, the situation that a concentration sensor is used for measuring the oxygen concentration in the sealed space so that the working state of the nitrogen generation device can be controlled is avoided, the cost is reduced, the two states, namely the opened state and the unopened state, of the sealed space are distinguished, accurate control is conducted, unnecessary working time of the nitrogen generation device is not increased, and the refrigerator energy consumption is reduced.

Owner:HAIER SMART HOME CO LTD

A fully automatic rubber part demoulding device

The invention belongs to the technical field of workpiece demoulding, and specifically relates to a fully automatic rubber part demoulding device, which includes a top plate and a turntable; a rectangular groove is opened on the lower surface of the top plate, and a horizontally placed rotating shaft is rotatably connected in the rectangular groove , one end of the rotating shaft is fixedly connected with the output shaft of the motor; the middle part of the rotating shaft is fixedly connected with the first bevel gear; the middle part of the rotating shaft is provided with a fixed plate; the upper surface of the fixed plate is connected with a vertically placed rotating shaft , the upper end of the rotating shaft is fixedly connected with the second bevel gear; the lower end of the rotating shaft passes through the fixed plate design, and the lower end of the rotating shaft is fixedly connected with the first telescopic rod; the lower surface of the first telescopic rod is fixedly connected with The turntable is designed in a cylindrical structure, and the lower surface of the turntable is provided with uniformly arranged suction cups; the invention makes the rubber parts rotate around the core and receive an upward pulling force, thereby effectively reducing the difficulty of demoulding the rubber parts, and There is no need to take out the core in advance, which improves the production efficiency of the enterprise.

Owner:ZHEJIANG TIANTAI XIANGHE IND CO LTD

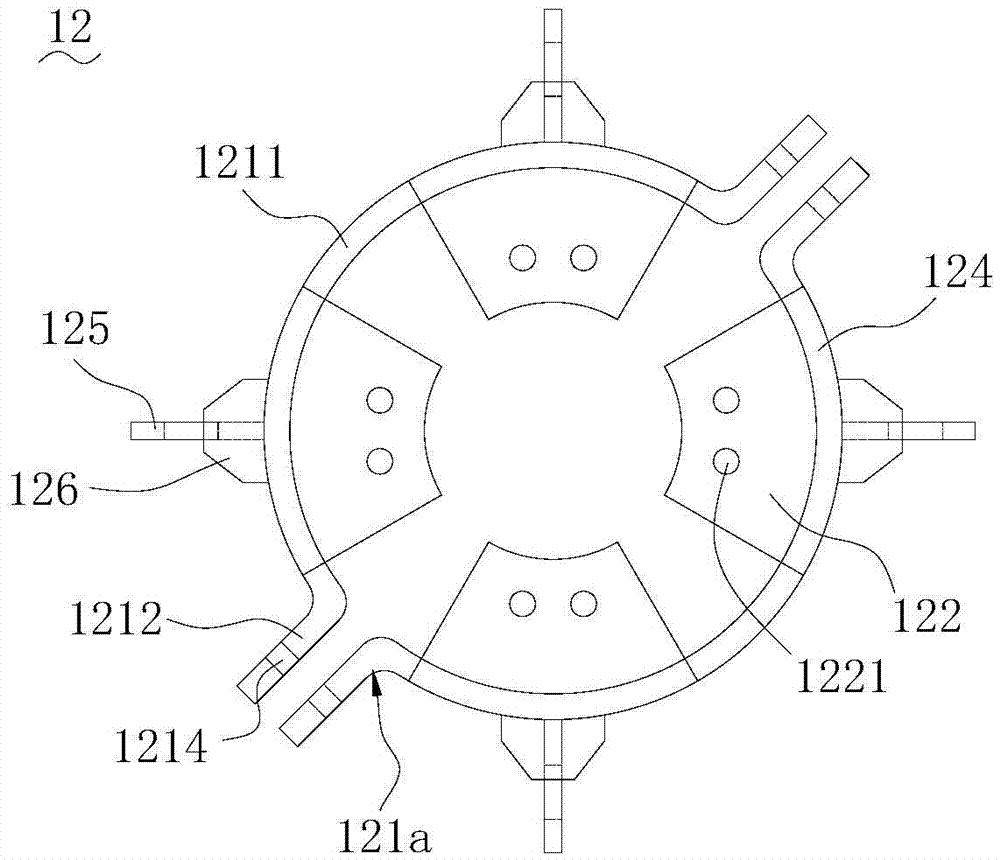

Rotary motor

InactiveCN102570698AFastening is easyGuaranteed insulation distanceElectric machinesSupports/enclosures/casingsEngineeringRelay

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com