A fully automatic rubber part demoulding device

A demoulding device and technology of rubber parts, applied in the field of workpiece demoulding, can solve the problems of difficult demoulding of cylindrical rubber parts sealed at one end, complex disassembly and installation process of core plates, and reduced production efficiency of enterprises, so as to reduce working hours , Accelerate separation and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

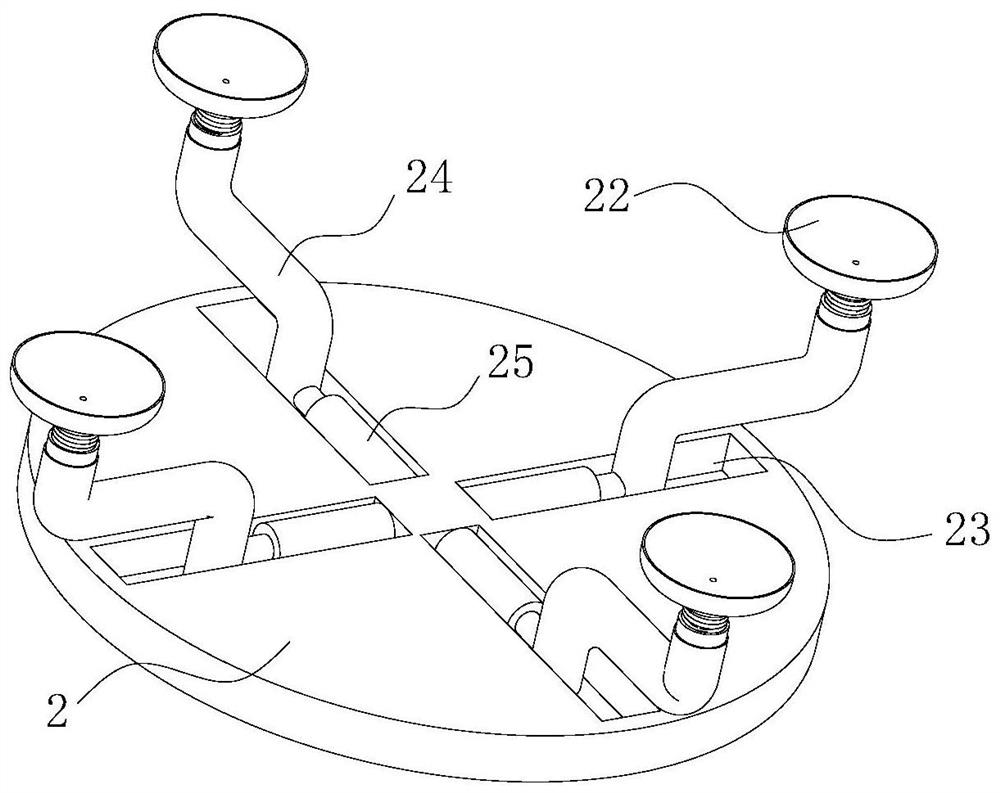

[0024] As an embodiment of the present invention, the lower surface of the turntable 2 is provided with evenly arranged second chute 23 along the radial direction of the turntable 2, and the second chute 23 is slidably connected with an "'S" shape design. The connecting rod 24, the end of the connecting rod 24 away from the turntable 2 is fixedly connected with a suction cup 22; a third telescopic rod 25 is arranged between the suction cup 22 and the inner wall of the second chute 23; during work, when the size When the rubber piece 41 is larger, the position of the suction cup 22 can be controlled by controlling the telescopic movement of the third telescopic rod 25, and then the size of the rubber piece 41 absorbed by the suction cup 22 can be controlled to prevent the pair of suction cups 22 from being lowered due to the large size of the rubber piece 41. The adsorption effect of the rubber part 41, thereby improving the practicability and scope of use of the device; and for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com