High efficiency automatic wok

A fully automatic and high-efficiency technology, applied in the field of machinery, can solve the problems of increasing the physical energy consumption, large physical strength and heavy weight of chefs, and achieve good economic and social benefits, high practicability, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

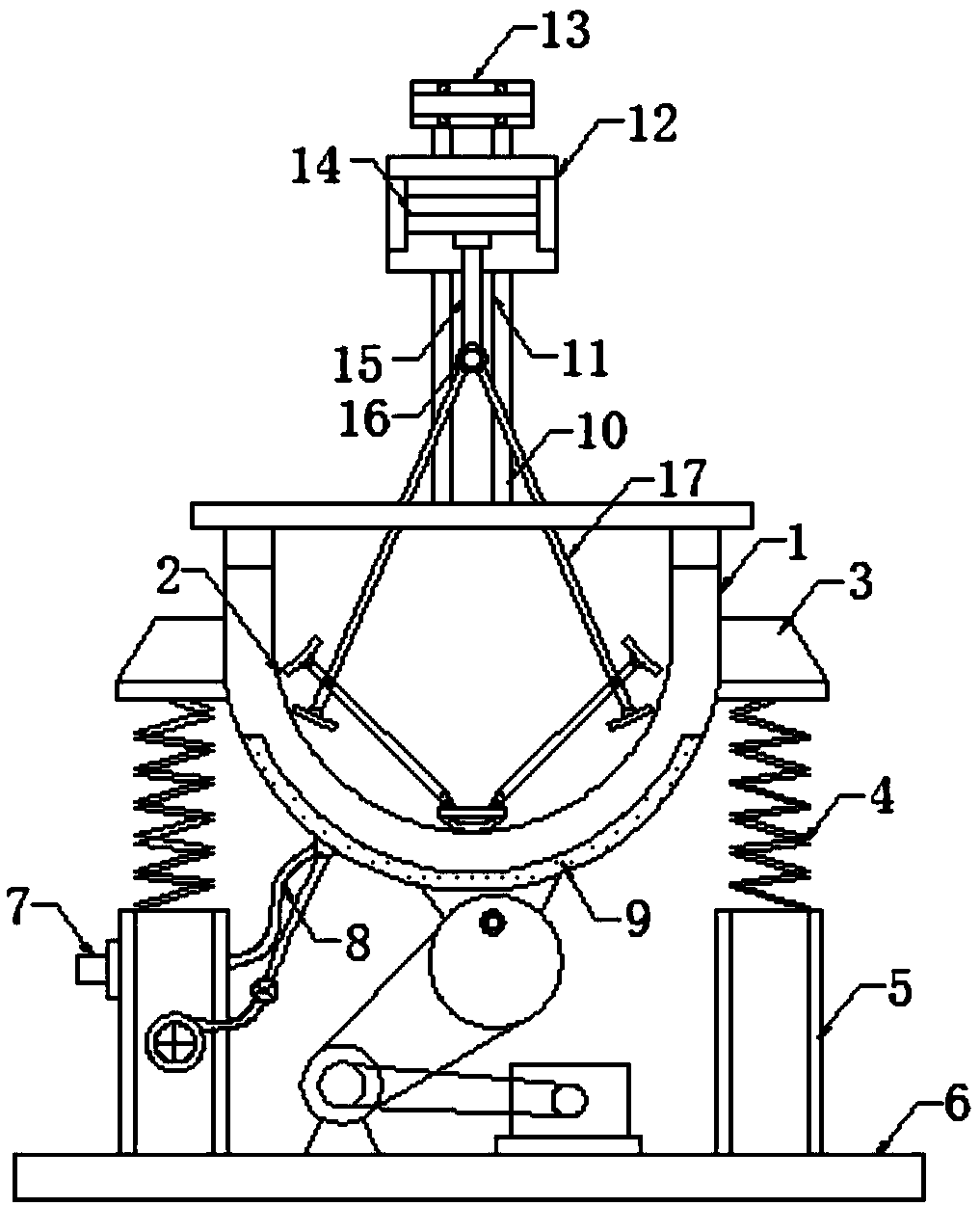

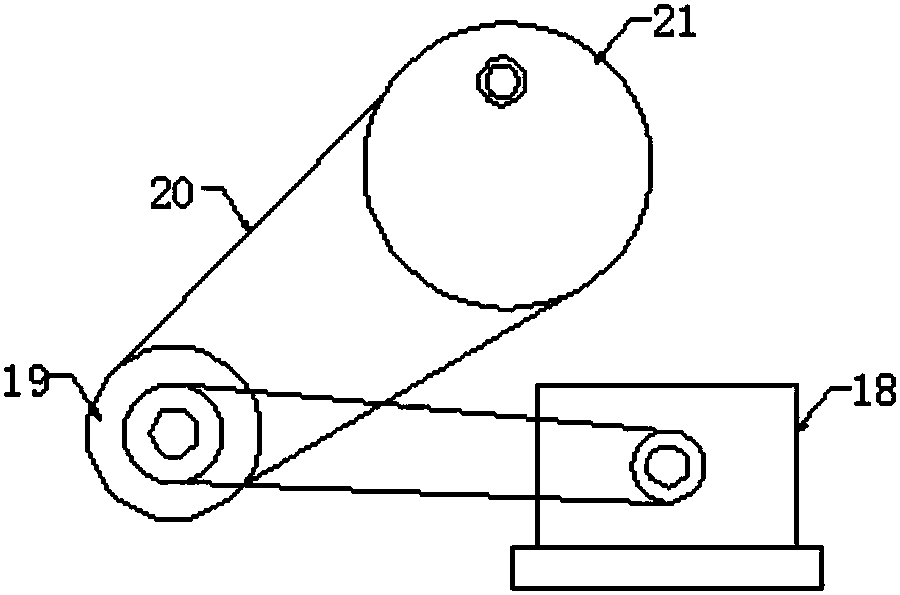

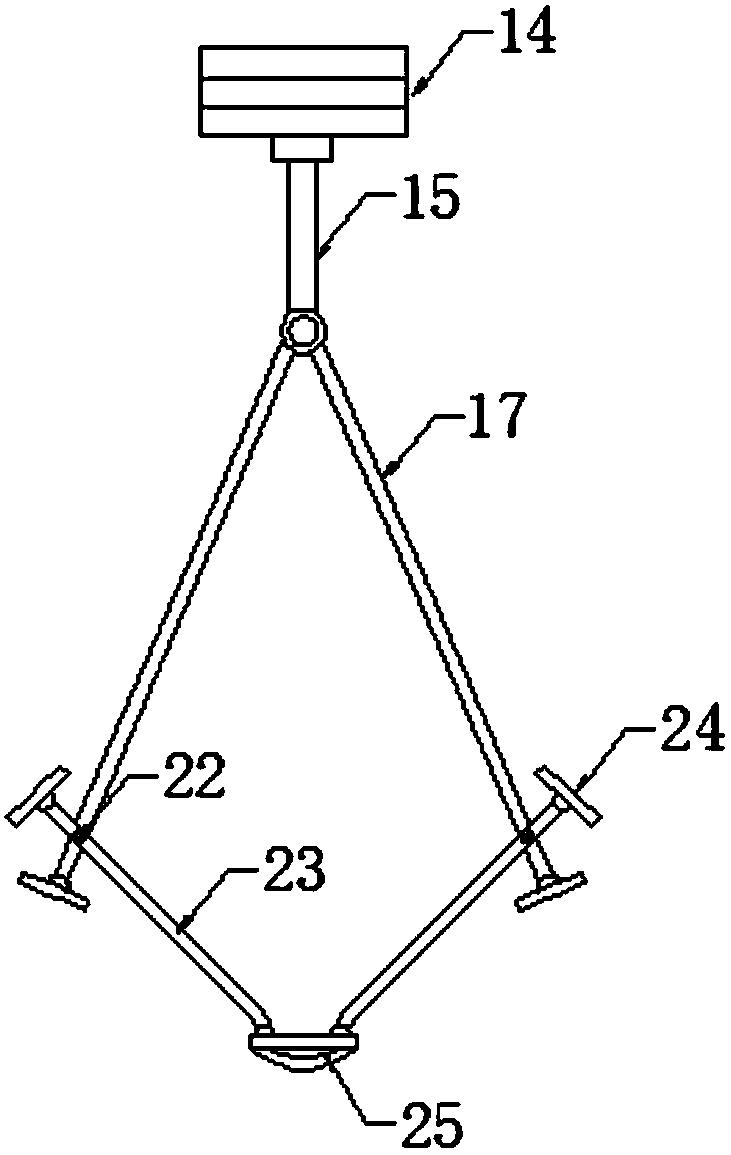

[0021] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a high-efficiency fully automatic wok, including an outer pot body 1, an inner pot body 2, an ear plate 3, a buffer spring 4, a support seat 5, a base 6, and a gas inlet 7 , intake pipe 8, gas cooker head 9, positioning frame 10, slide rail 11, slide seat 12, reciprocating motor 13, rotating motor 14, main shaft 15, movable shaft ring 16, stirring main rod 17, driving motor 18, transmission wheel 19, Transmission belt 20, eccentric wheel 21, connecting piece 22, stirring auxiliary rod 23, brush head 24 and stirring fan blade 25, inner pot body 2 is fixedly placed in outer pot body 1, and the port of inner pot body 2 is connected with outer pot body 1 The end edge is tightly pressed, and the two ends of the outer pot body 1 are fixed with ear plates 3, and the bottom side of the outer pot body 1 is provided with a base 6, and the support seat 5 is fixed on the base 6 correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com