Hydraulic pressure test sealing tool and hydraulic pressure test method for pipelines

A hydraulic test and tooling technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of material waste and cost, and achieve a wide range of applications, simple structure, and convenient production and operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

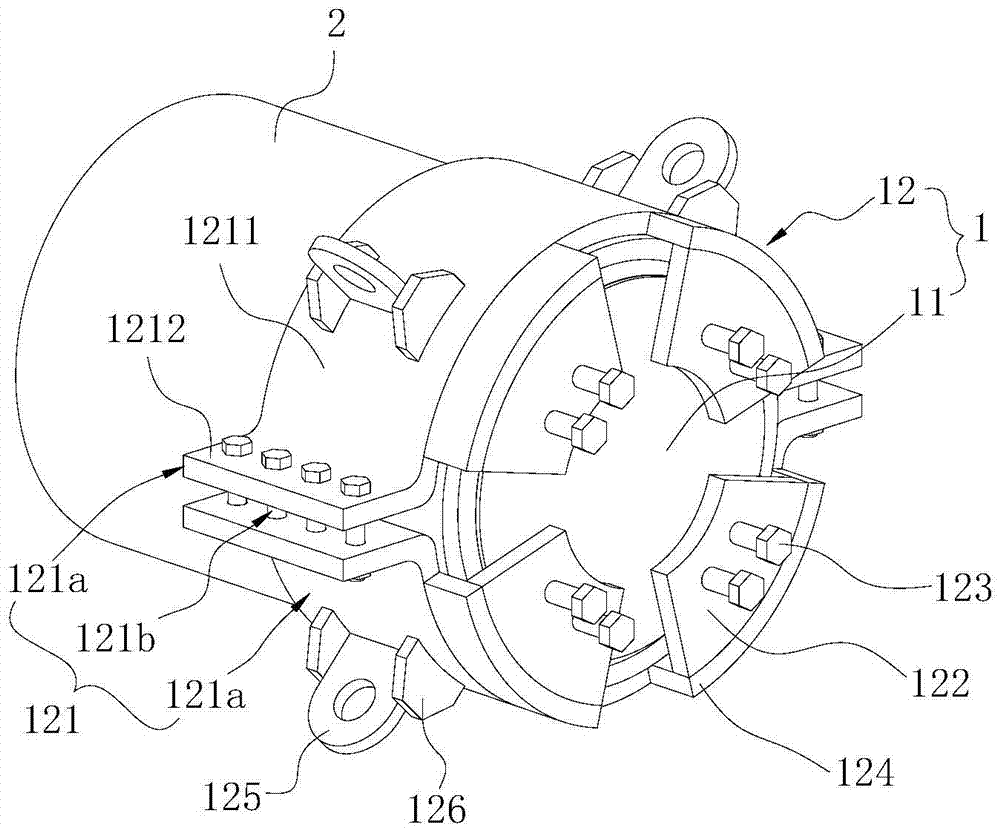

[0027] refer to figure 1 , the present invention provides a pipeline hydraulic test sealing tool 1 (hereinafter referred to as "sealing tool 1"), which can be used to seal the nozzle of the pipeline 2 during the hydraulic test of the pipeline 2.

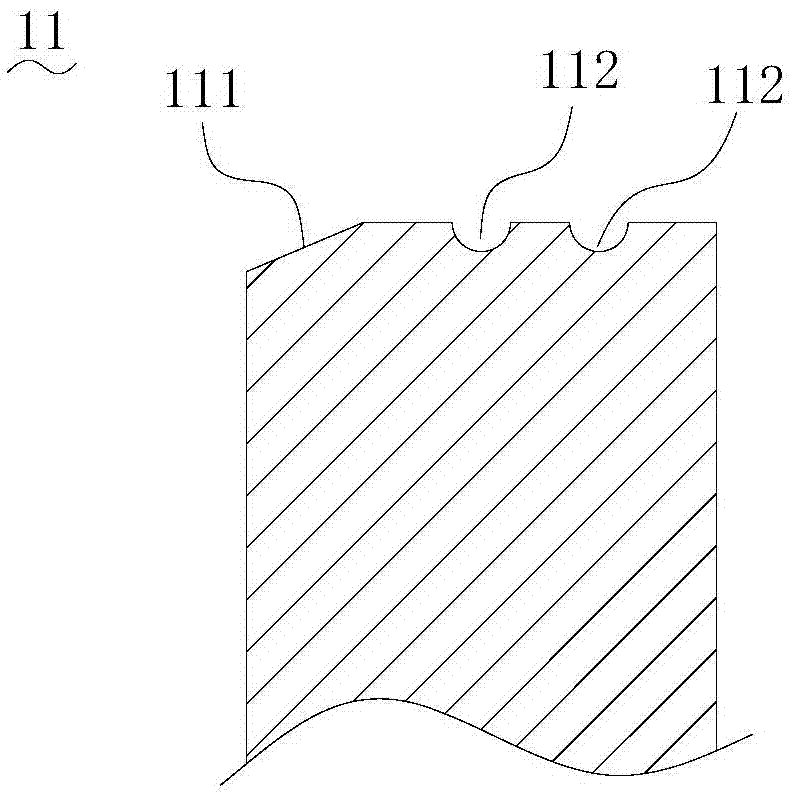

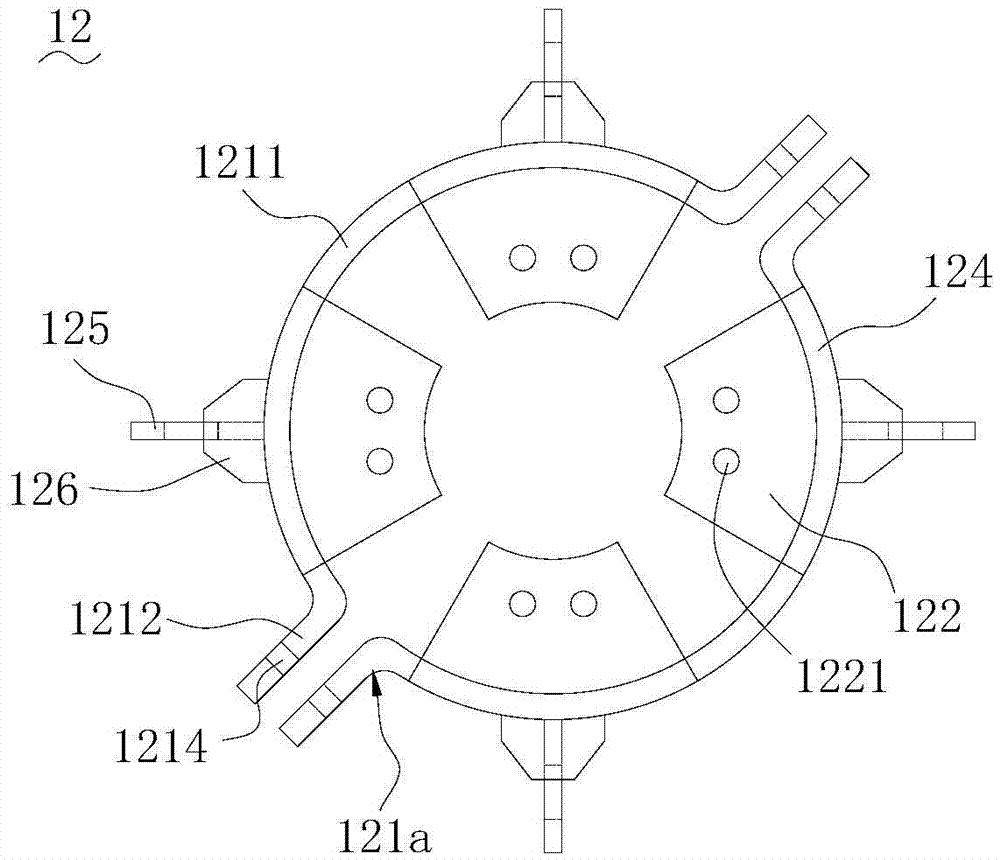

[0028] According to a preferred structure of the present invention, the sealing tool 1 includes a sealing plate 11 and a limiting clamp 12 .

[0029] The sealing plate 11 is used to fill the mouth of the pipeline 2 and seal the pipeline 2 . see also figure 1 with figure 2 The sealing plate 11 is adapted to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com