Thermally-conductive silicon grease coating device

A technology of coating device and heat-conducting silicone grease, which is applied in the direction of rotary printing machine, printing machine, printing machine, etc., can solve the problems of high manufacturing cost, few types of modules, and non-replaceable stencil, so as to avoid working hours and station, saving production space, and improving coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

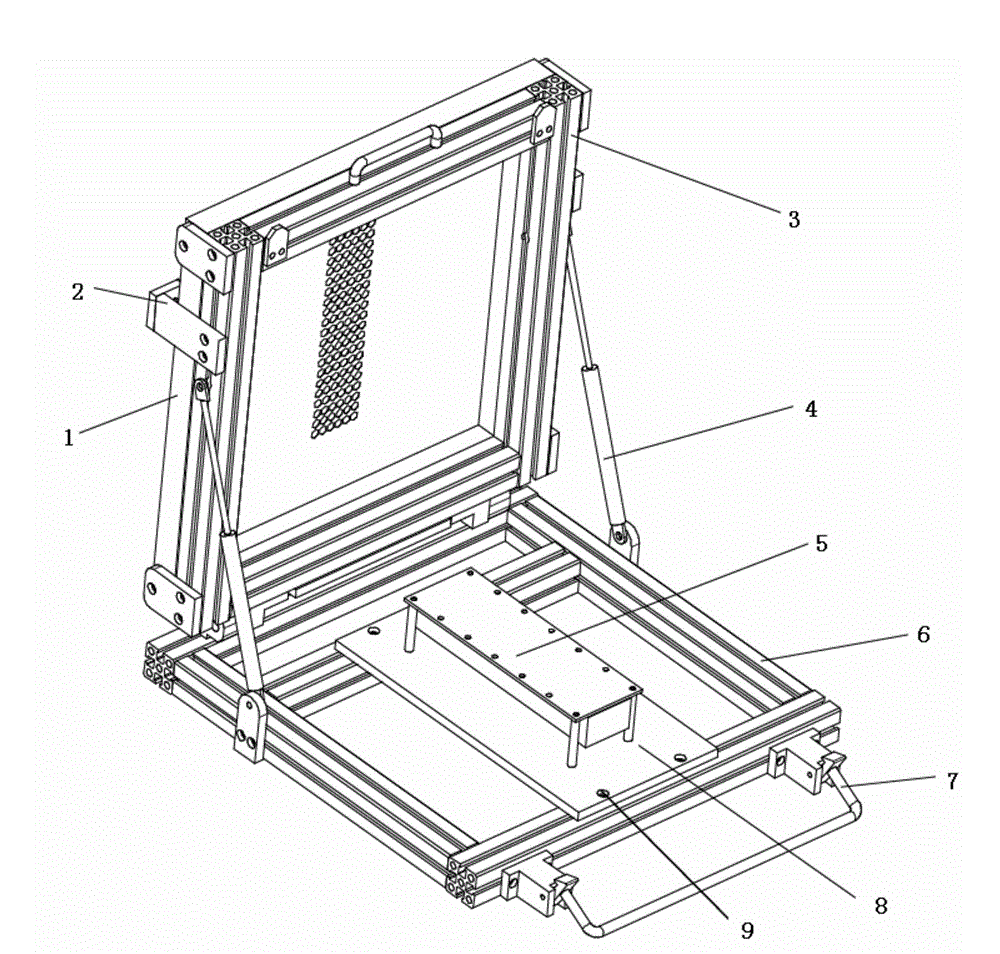

[0021] like figure 1 and figure 2 As shown, the thermal conductive silicone grease coating device of the present invention includes a main body frame 6, a screen printing screen 1, a screen printing screen support 3 and a module support 8; the screen printing screen 1 is inserted into the screen printing screen support 3; The module support 8 is fixed on the main frame 6; the main frame 6 and the screen printing screen support 3 are connected as a whole through the pneumatic support rod 4 and the rotating shaft, and the pneumatic support rod realizes the support of the screen support and the main frame; the main body The outer end of the frame 6 is fitted with a locking lever 7 .

[0022] The module 5 is fixed on the module support 8, and the positioning key and the direction mark are used to realize the accurate positioning of the module sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com