Absorption system for industrial exhaust gas treatment

An absorption system, industrial waste gas technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of poor hydrogen chloride absorption effect, large floor space, dilute hydrochloric acid concentration, etc., to achieve automatic operation, flexible use, The effect of slowing down the rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

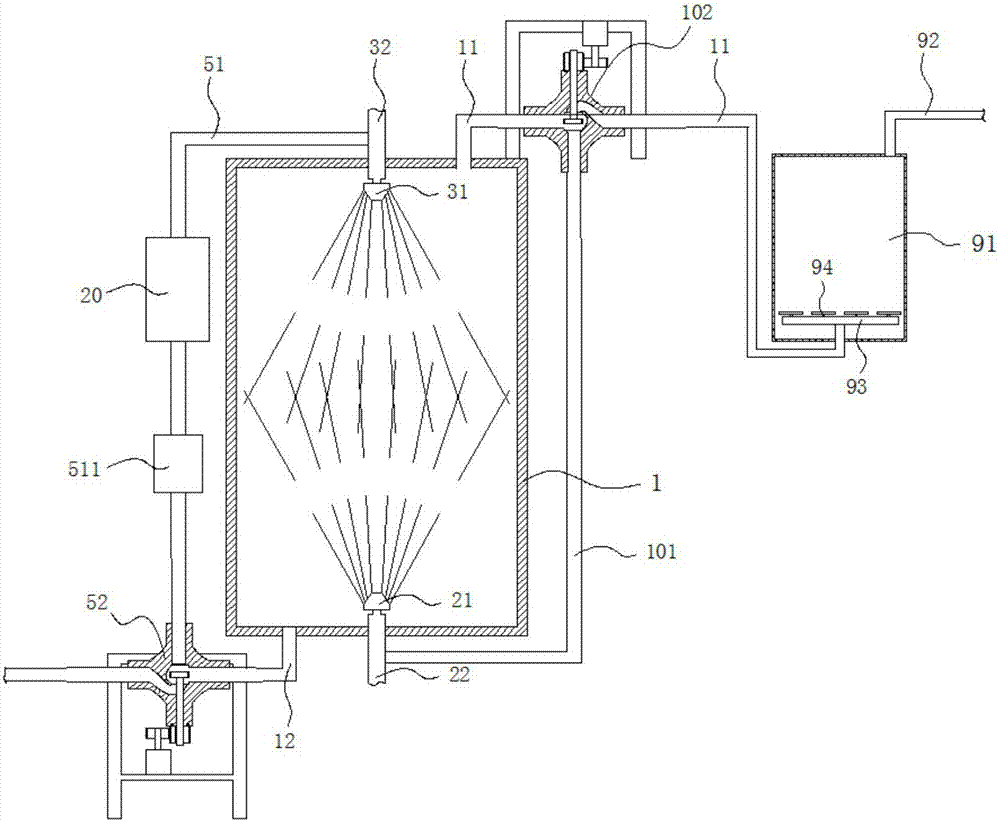

[0024] Such as Figure 1-3 As shown, an absorption system for industrial waste gas treatment includes a tower body 1, an air injection device, a water injection device, a gas recovery device, a liquid recovery device, an exhaust neutralization device, and a condensing unit matched with the liquid recovery device. Device 20; the air injection device includes an air injection part 21 located at the lower part of the tower body and an air intake pipe 22 connected with the air injection part, and the air injection part 21 is an air nozzle purchased directly on the market; the upper part of the tower body An air outlet pipe 11 is provided so that the exhaust gas enters from the bottom of the absorption tower and is sprayed upwards through the air spraying device. Pipeline 32, the water spraying part 31 is a spray head purchased directly on the market; the lower part of the tower body is provided with a liquid outlet pipe 12, so that water enters from the upper part of the absorptio...

Embodiment 2

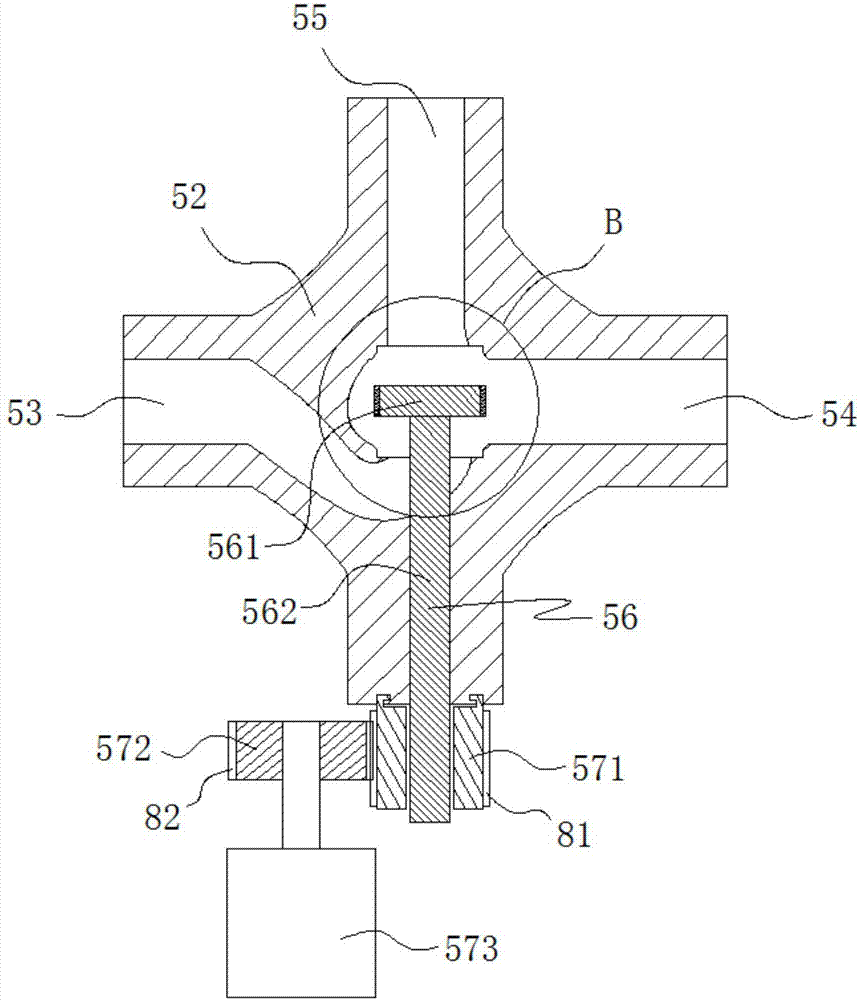

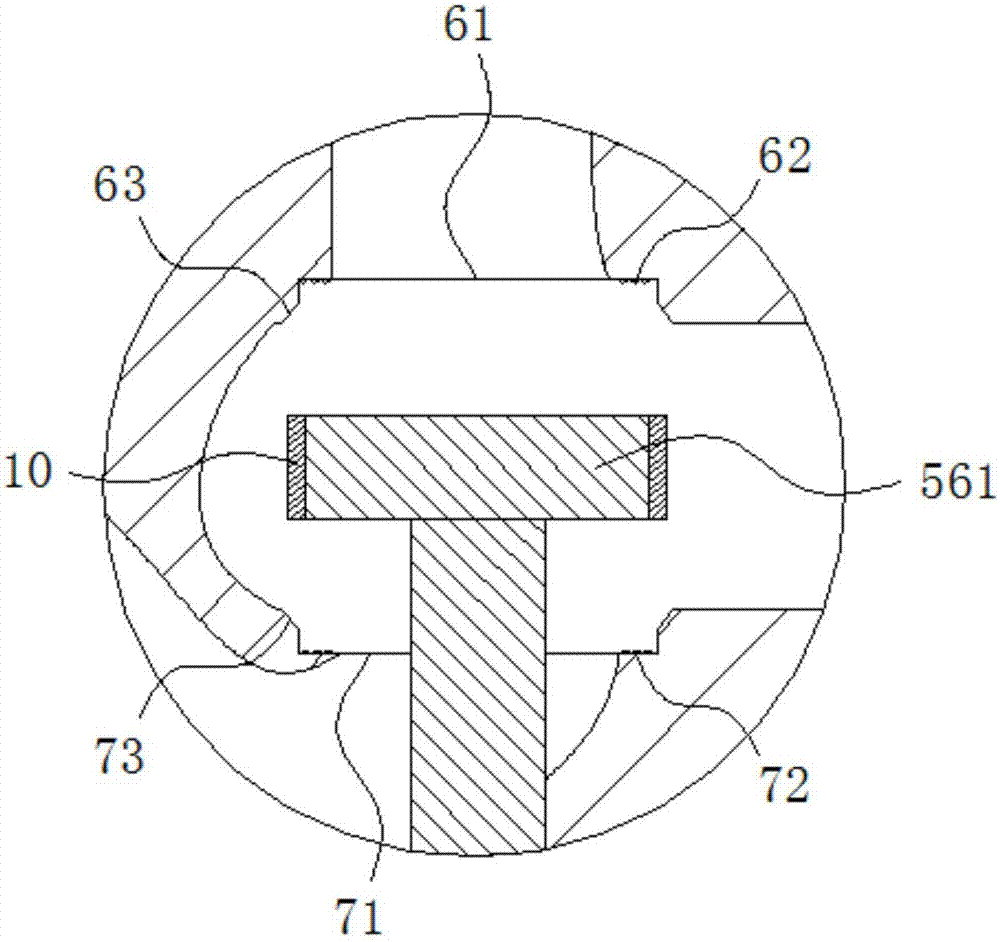

[0034] Such as Figure 4-6 As shown, the difference between this embodiment and Embodiment 1 lies in the structure of the connector: the connector 52 is provided with a spherical cavity 521, the liquid inlet channel 53, the first liquid outlet channel 54, the second liquid outlet channel 55 communicate with the spherical cavity 521 respectively, and the axes of the liquid inlet channel 53 and the first liquid outlet channel 54 are in the same straight line, and the axes of the liquid inlet channel 53 and the second liquid outlet channel 55 are perpendicular to each other; the movable member 56 includes a spherical The rotating member 561, the first liquid guiding channel 562 and the second liquid guiding channel 563, the spherical rotating member 561 is rotatably arranged in the spherical cavity, and the first liquid guiding channel 562 is eccentrically arranged in the spherical cavity. In the rotating part, the eccentric penetration here refers to not passing through the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com