Airbag module for vehicle occupant restraint system

An occupant restraint and airbag technology, applied in vehicle components, vehicle safety arrangements, pedestrian/occupant safety arrangements, etc., can solve the problem of expensive foils and achieve the effect of preventing separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

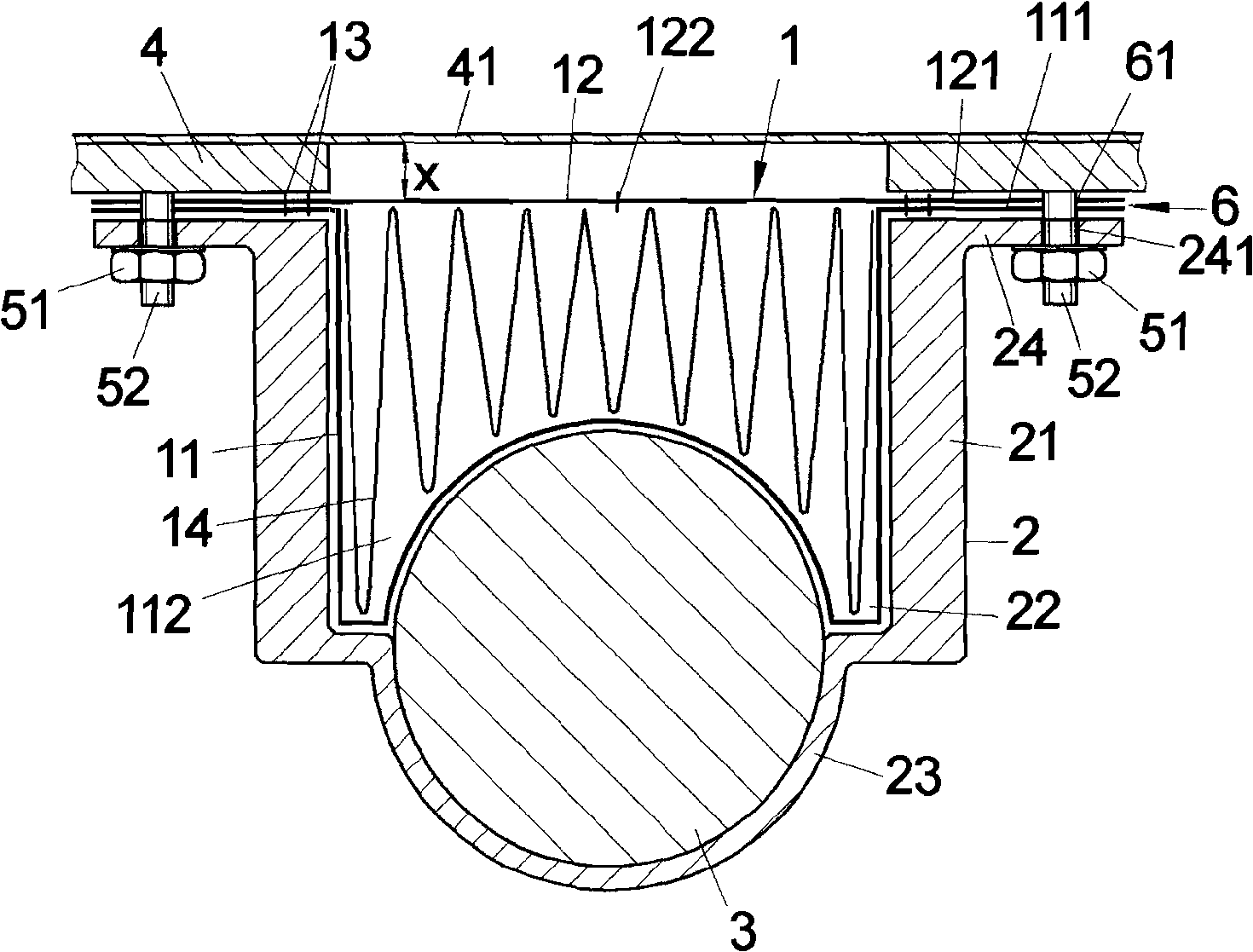

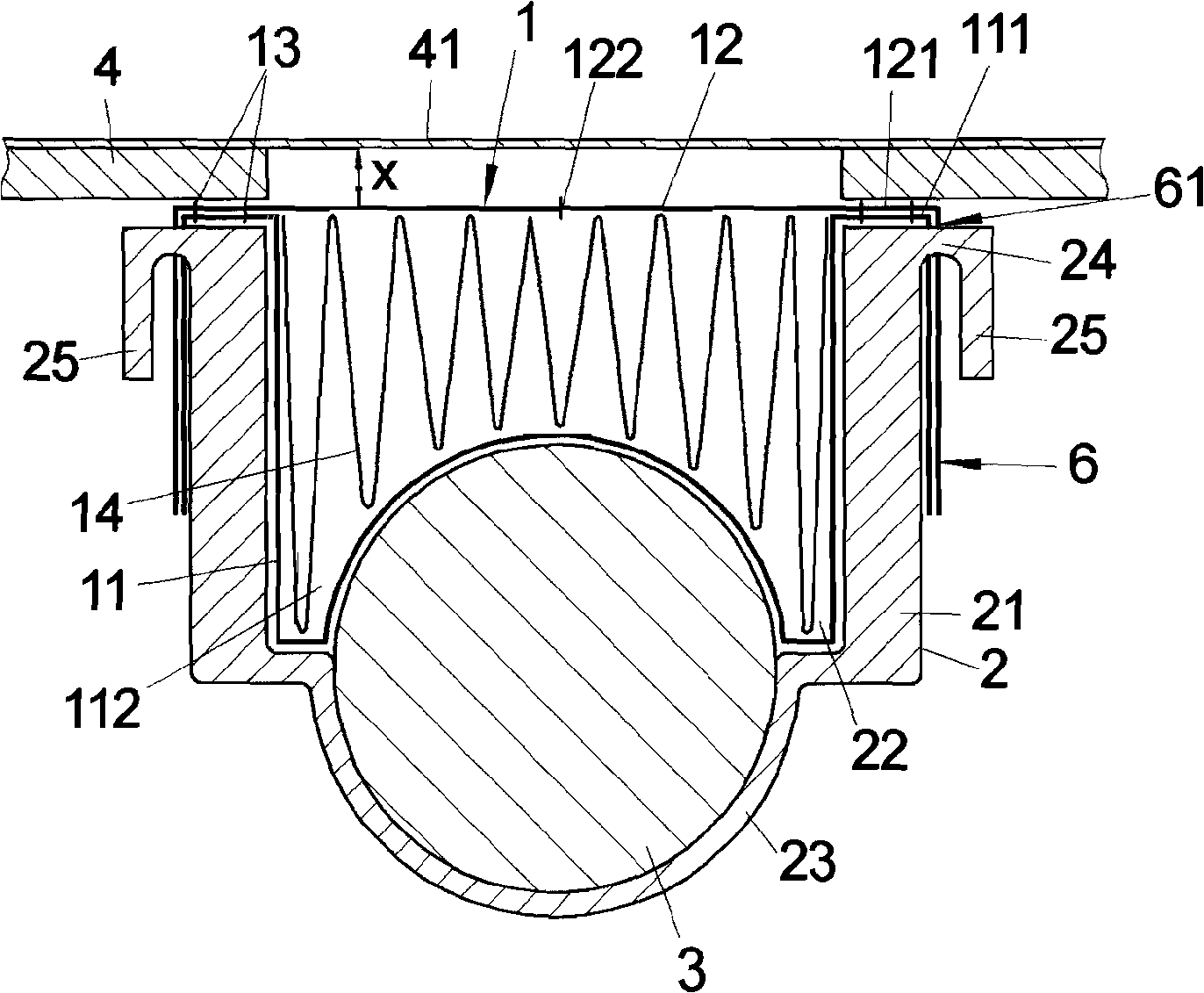

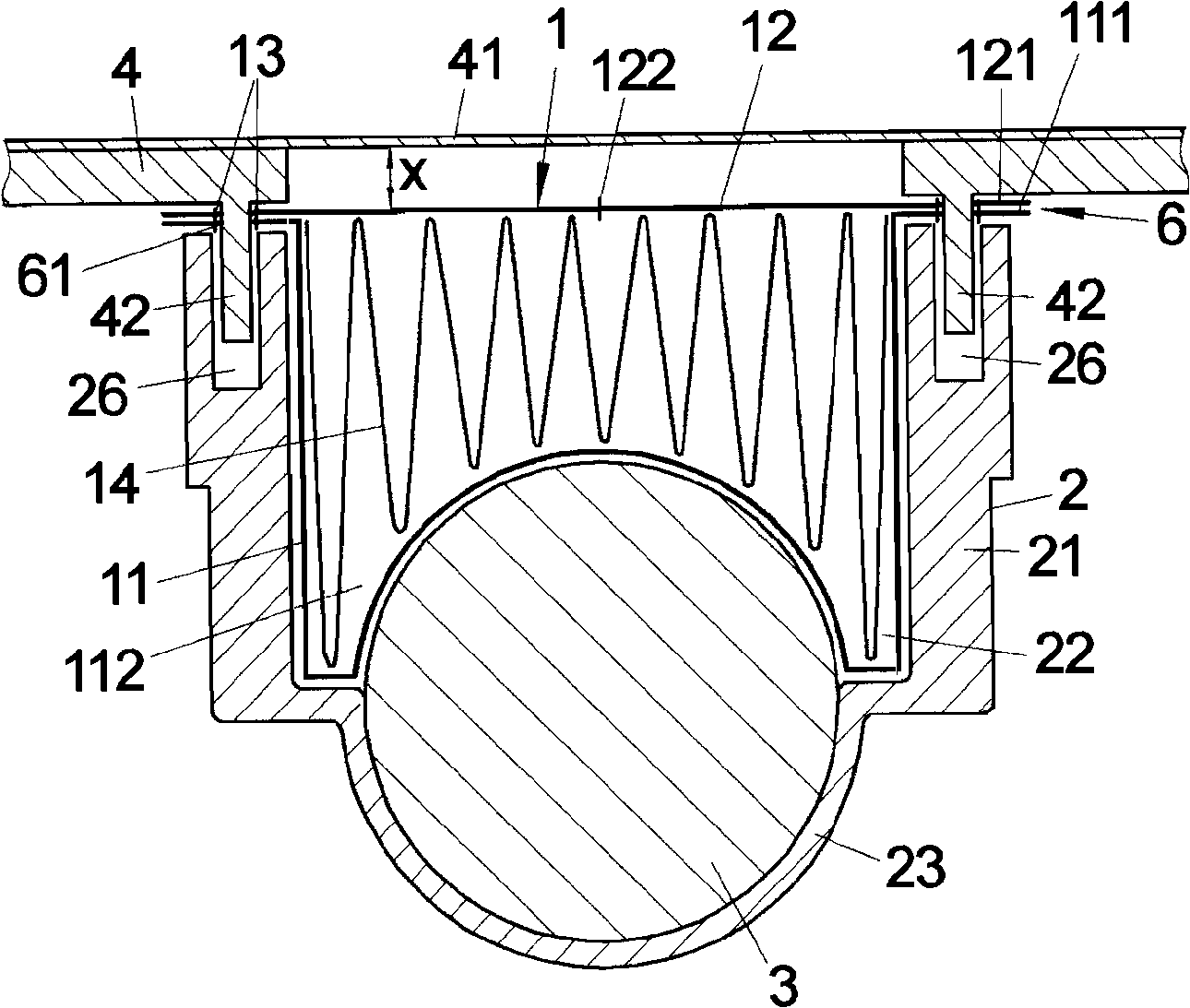

[0027] figure 1 An airbag module is shown with an airbag package 1 , a module housing 2 and a gas generator 3 . Via the fastening elements 51 , 52 the airbag module is connected to an adjacent structure, for example to the instrument panel 4 of the vehicle.

[0028] The module housing 2 forms by means of side walls 21 a housing 22 for arranging the airbag package 1 . The housing 2 additionally comprises a fastening region 23 for the gas generator 3 . In this respect, the illustrated housing 2 also illustrates a gas generator mount. However, it can be provided that the gas generator support is designed as a separate component.

[0029] The gas generator is only used as an example in the figure 1 in the icon. Essentially any gas generator can be used, where a diffuser (not shown) can be used together.

[0030] The module housing 2 furthermore forms a flange 24 for fastening the airbag module to the instrument panel 4 . The flange 24 has an opening 241 which allows the pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com