Testing drive for a stepping switch

A driving device and stepping switch technology, applied in electric switches, measuring devices, instruments, etc., can solve problems such as inspection and measurement cumbersome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

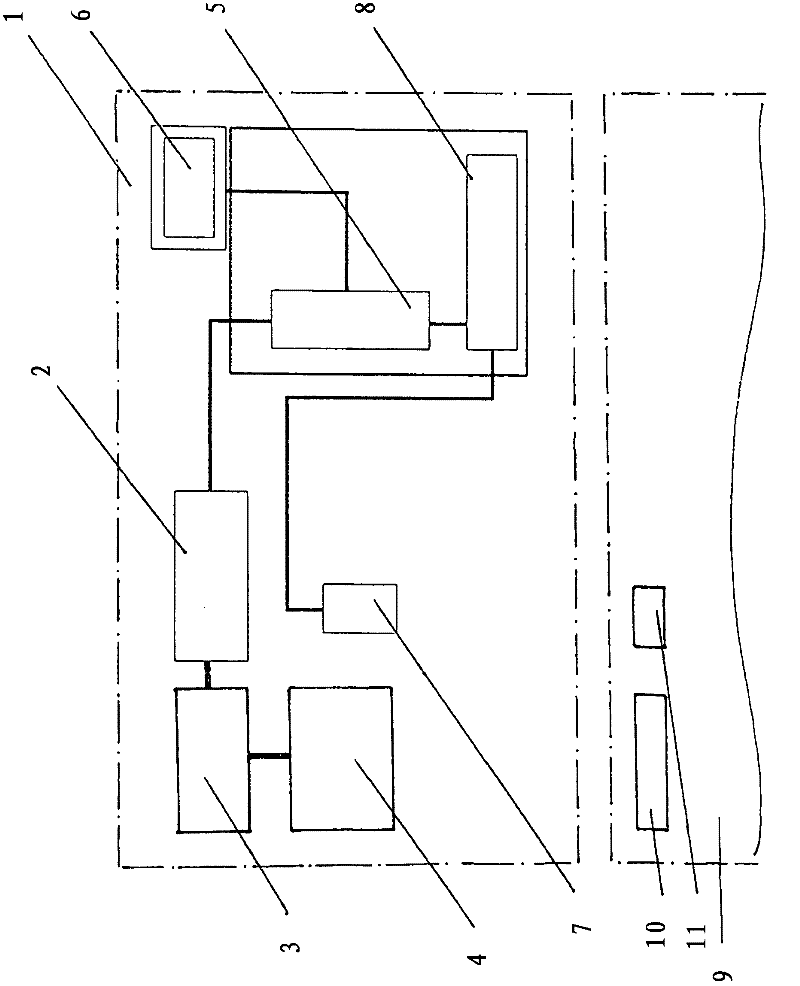

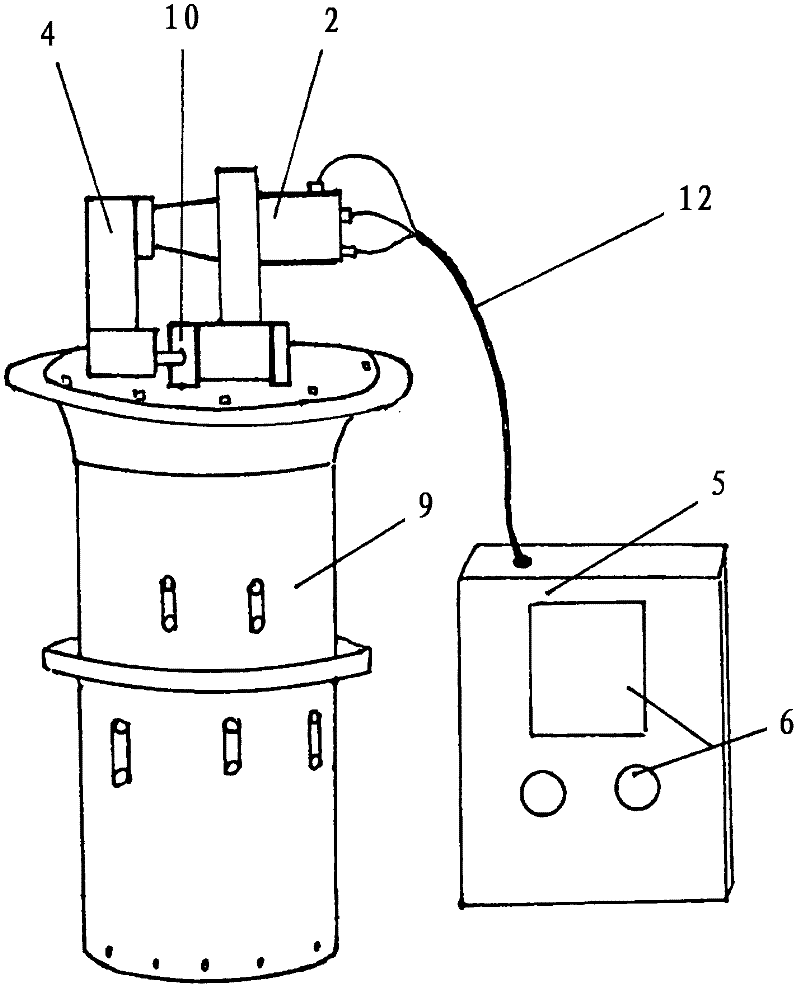

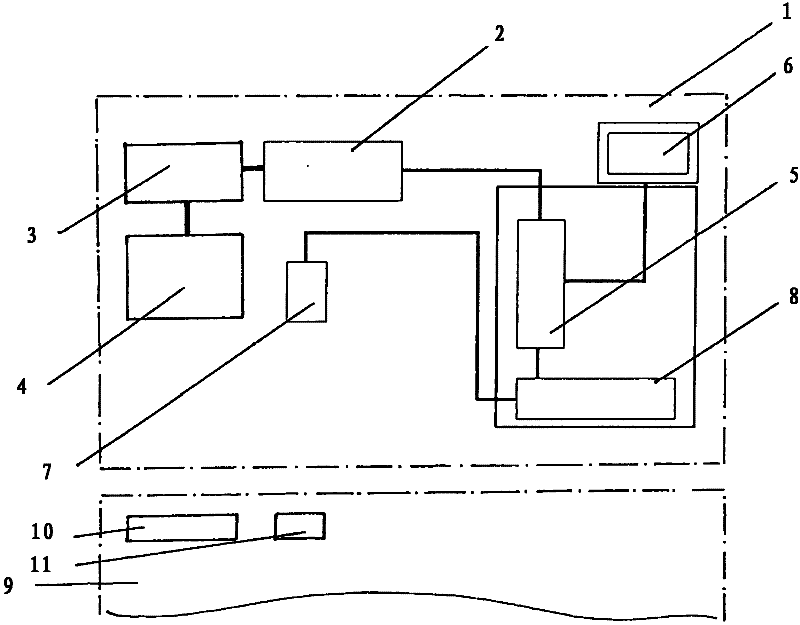

[0031] should first be based on figure 1 The illustration in illustrates the principle construction of the new test drive in more detail. The entire test drive 1 is surrounded here by a symbolic dashed line. The test drive has a servomotor 2 which acts on an adapter 4 via a transmission 3 . Furthermore, the test drive has a control unit 5 which cooperates with an operating unit 6 . Furthermore, a radio frequency identification (RFID) antenna 7 is provided, which is likewise connected to the control unit 5 via an RFID reader 8 . Below the test drive 1 , the upper part of the step switch 9 is likewise shown schematically here. There, an upper gear stage 10 is shown, to which the above-mentioned adapter 4 can be connected. Also shown is the likewise mentioned radio frequency identification tag 11 , which carries information about step switch-specific data and can be read by the radio frequency identification antenna 7 .

[0032] Thus, in the assembled state of the test drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com