On-load tap changer

A technology of on-load tapping and switching, which is applied in the direction of electric switches, high-voltage/high-current switches, inductors, etc., can solve the problems of high cost and expensive transformer boards, and achieve the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

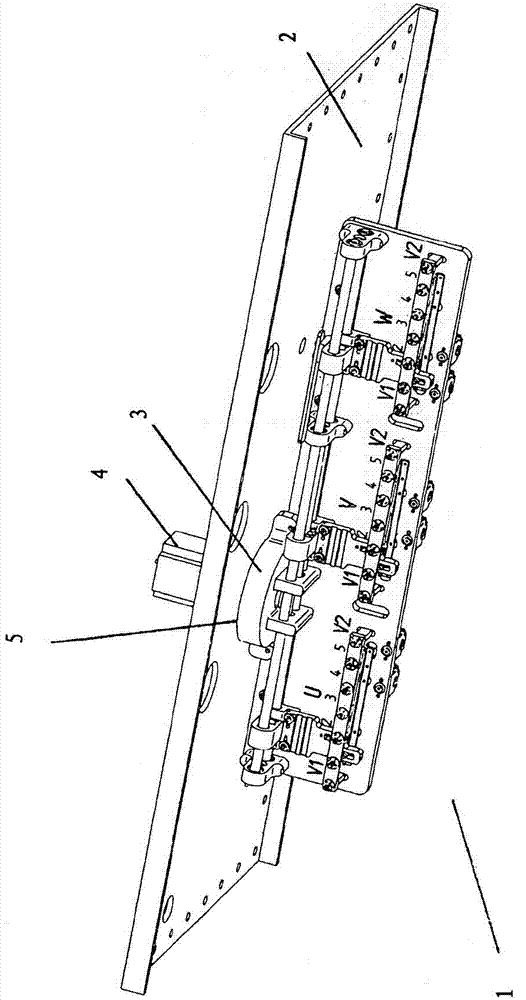

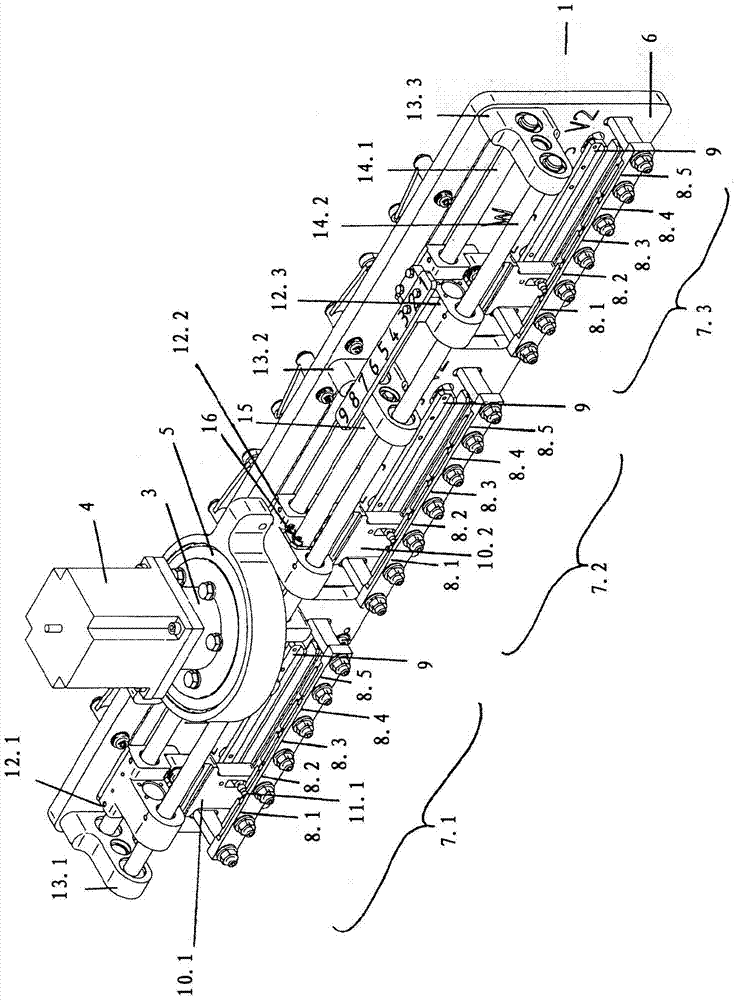

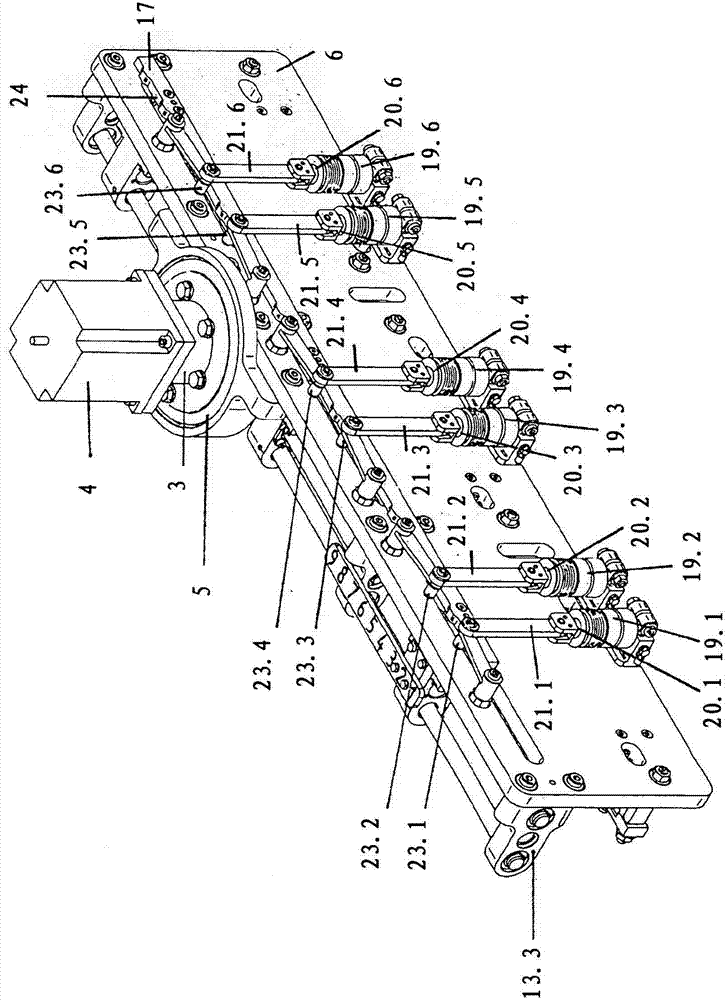

[0030] exist figure 1 The figure shows a perspective view of an on-load tap-changer 1 according to the invention, which is arranged directly below a transformer housing 2 of a tapped transformer, not shown in greater detail. A more detailed description of the components of on-load tap-changer 1 and their function can be obtained from the following description of the drawings. Such tapped transformers, which are well known from the prior art, comprise a transformer housing filled with insulating oil, in which at least one winding is arranged on an iron yoke. The winding is composed of a main winding and an adjusting winding, and a plurality of winding sub-joints are arranged on the adjusting winding, and these winding sub-joints form an adjusting area. Furthermore, the on-load tap changer 1 has a drive module 3 fastened on the underside of the transformer housing 2 , which interacts with a motor drive 4 arranged on the opposite outer side of the transformer housing 2 . In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com