Paper tube hot extruder with marking device

A scribing device and extruder technology, which is applied in the direction of paperboard winding articles, etc., can solve the problems of easy deflection of roll film and failure of roll film, and achieve the effect of avoiding roll film deflection and meeting alignment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The working principle of the paper tube hot extruder with marking device of the present invention is the same as that of the prior art, and the prior art can be referred to, so it will not be described again. The difference between the present invention and the prior art is that the marking The line device is described in detail below:

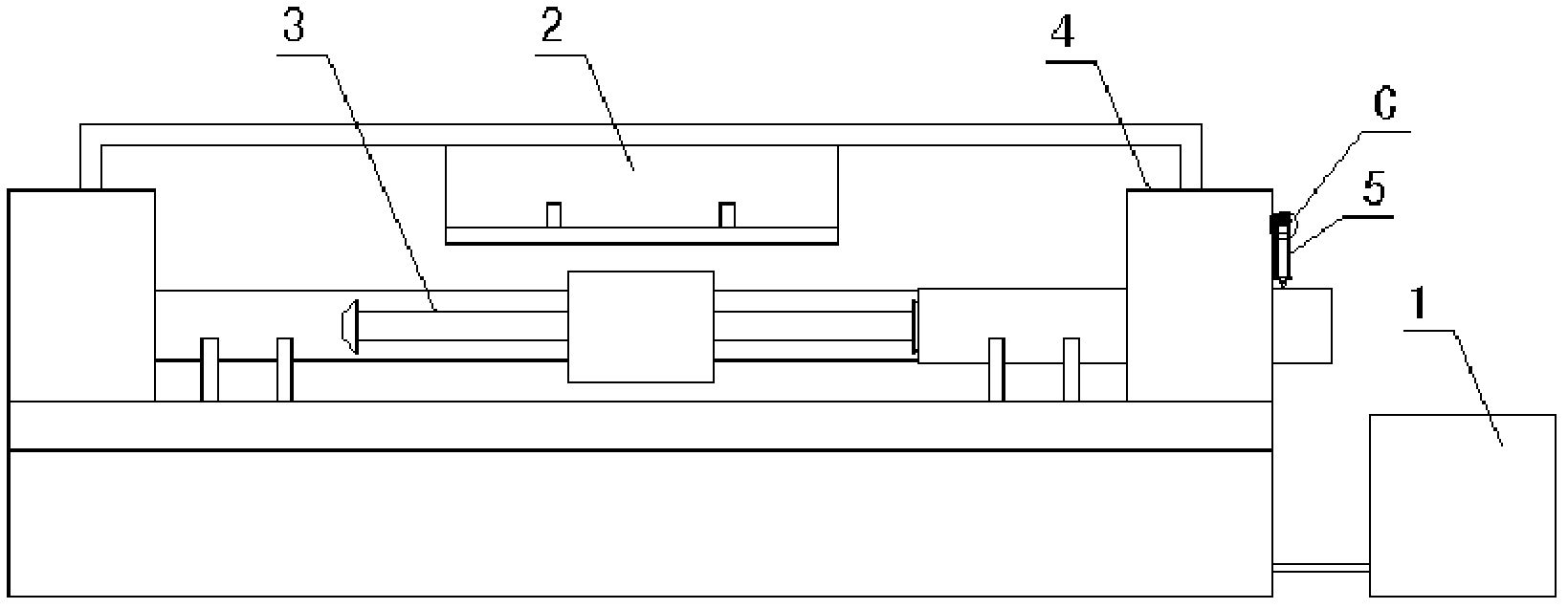

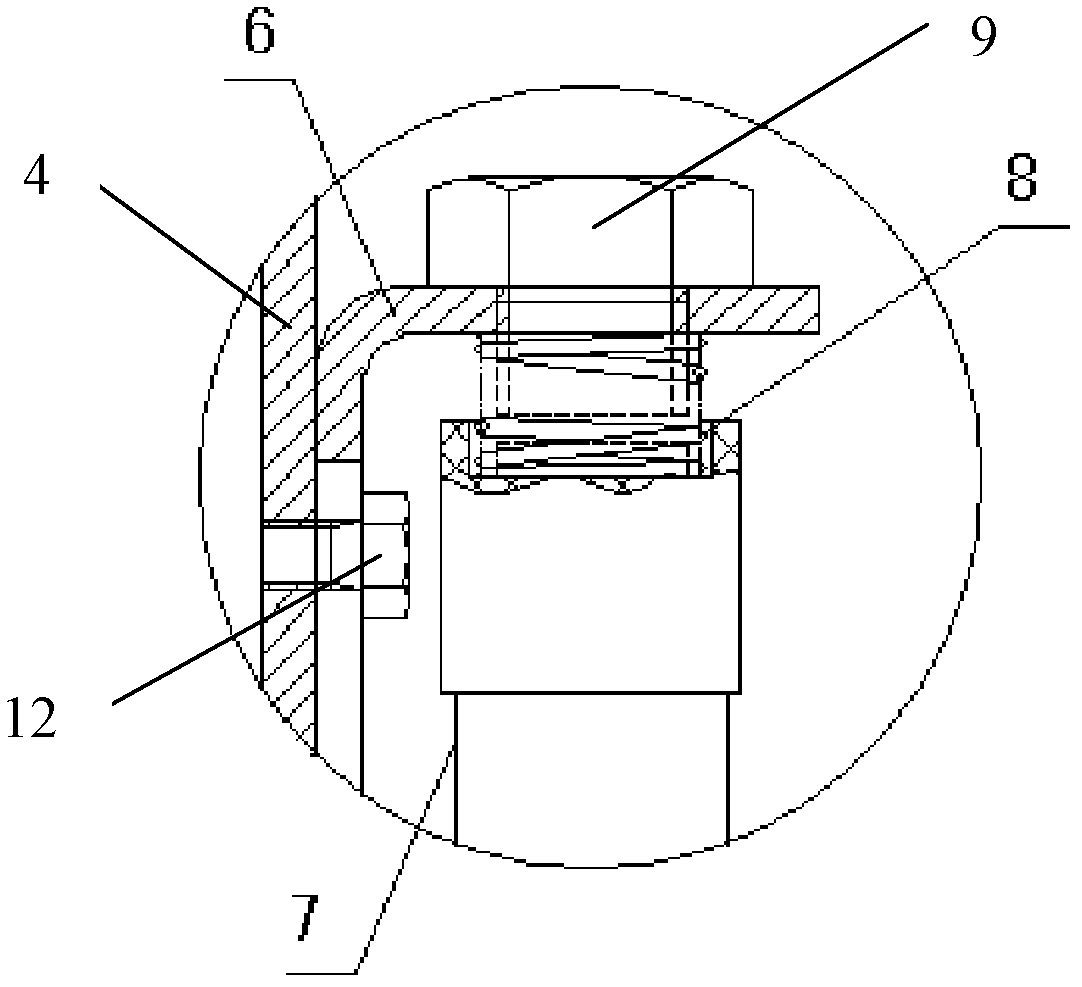

[0013] Such as figure 1 , 2 , 3, the paper tube hot extruder with marking device of the present invention comprises numerical control table 1, feeding mechanism 2, screw transmission mechanism 3, heating extrusion mechanism 4, at the output end of heating extrusion mechanism 4 A scribing device 5 that draws a straight line on the outer surface of the paper tube along with the output of the paper tube is provided.

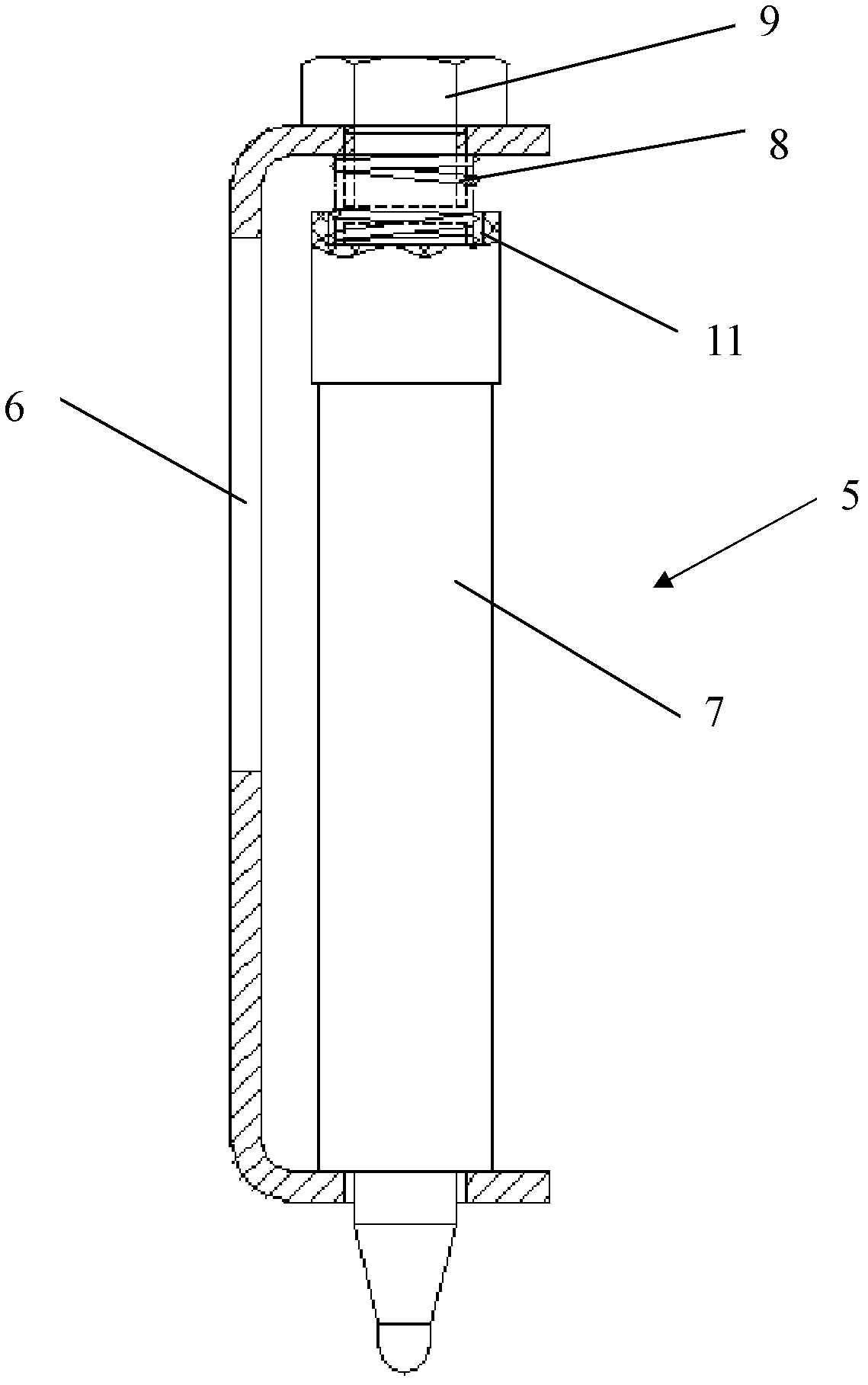

[0014] Specifically, the scribing device 5 includes a bracket 6, a scribing pen 7, a spring 8 and a bolt 9, and the bracket 6 is a half I-shaped of “[”, on three faces of the half I-shaped bracket 6 Form a through hole res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com