Piezoelectric swing yarn guide needle device for double-needle-bed tricot machine

A double-needle bed warp knitting machine and yarn guide needle technology, which is applied in warp knitting, knitting, textiles and papermaking, etc., to achieve the effects of improving aesthetics and comfort, increasing freedom, and overcoming technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

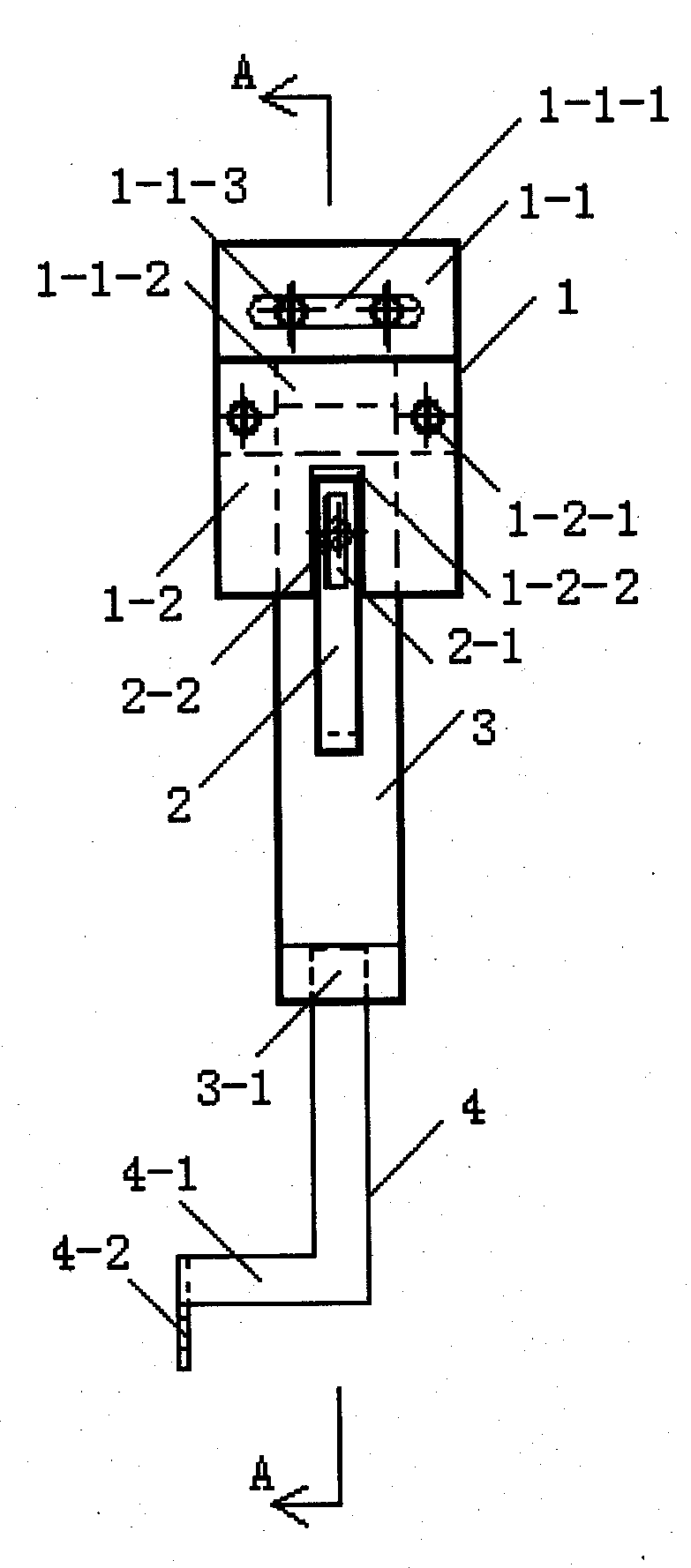

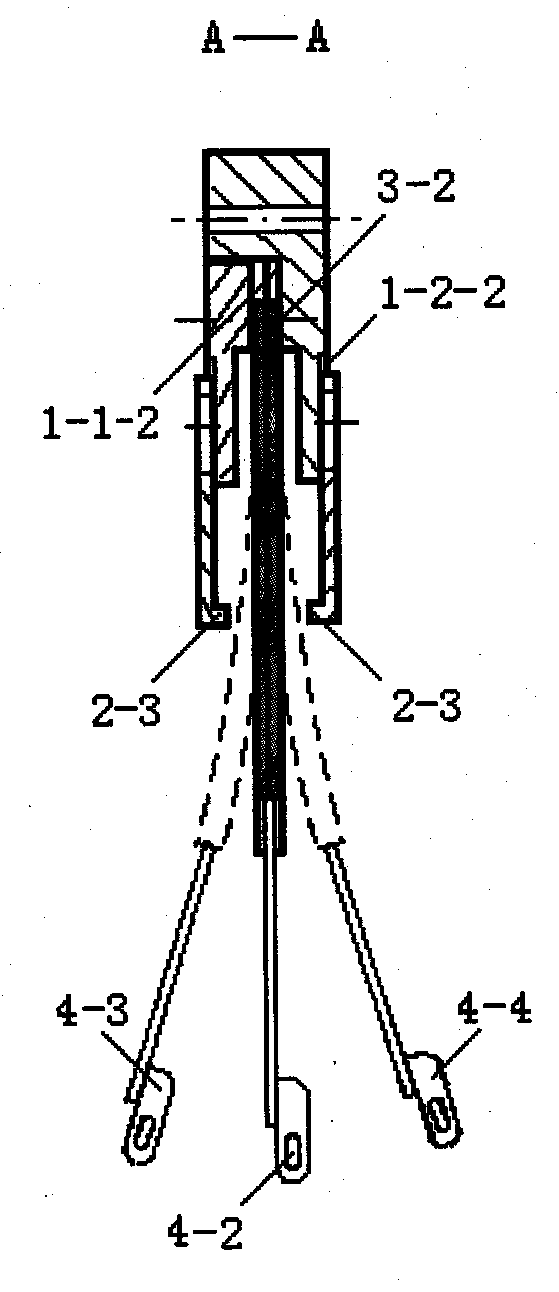

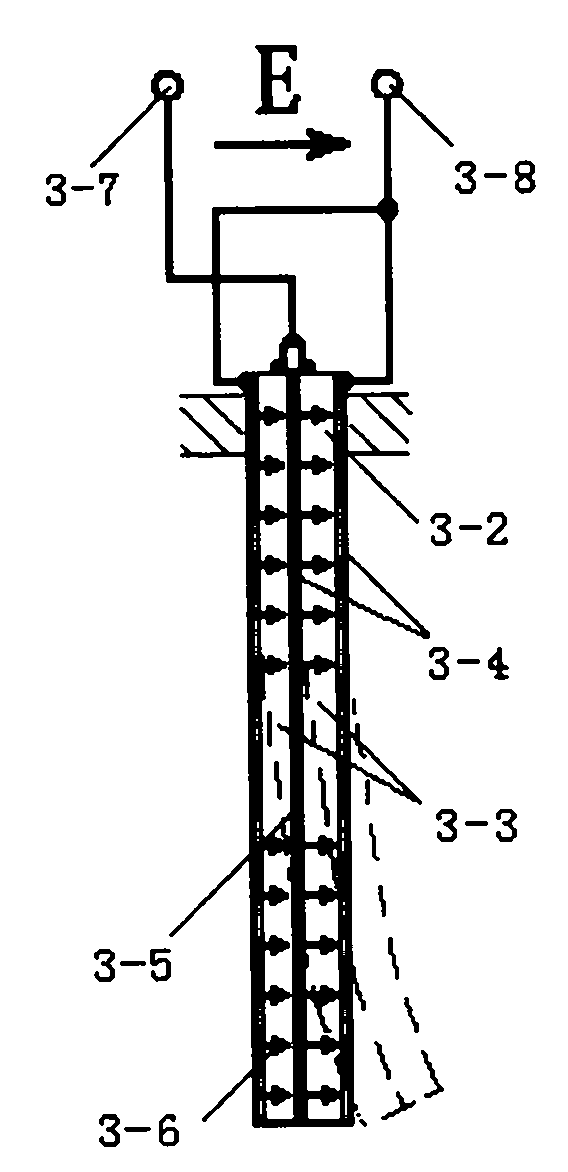

[0026] like figure 1 As shown, it is a schematic diagram of the front view of the piezoelectric type oscillating yarn guide device used for the seam on the right side. Composition of 4 yarn needles. like figure 2 shown, for figure 1 Middle A-A cuts to the sectional view, is inserted into the installation fixing screw 1-1-1 in the installation adjustment hole 1-1-1 and is fixed on the support base 1 on the comb plate (not shown in the figure) of the double-needle bed warp knitting machine. Base 1-1 and cover plate 1-2. The cover plate 1-2 is fixed on the base 1-1 by the cover plate fixing screw 1-2-1; the base 1-1 is provided with a swing plate chute 1-1-2, and the swing plate chute 1-1-2 The width is consistent with the width of the swing piece 3, the base 1-1 and the cover plate 1-2 clamp the swing piece 3 whose upper end is inserted into the swing piece chute 1-1-2 in the middle of the support seat 1, and the cover plate fixes the screw 1-2-1 clamping; the limit piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com